PRF Composite Materials releases RP542-4 toughened prepreg system for UD and woven fabrics

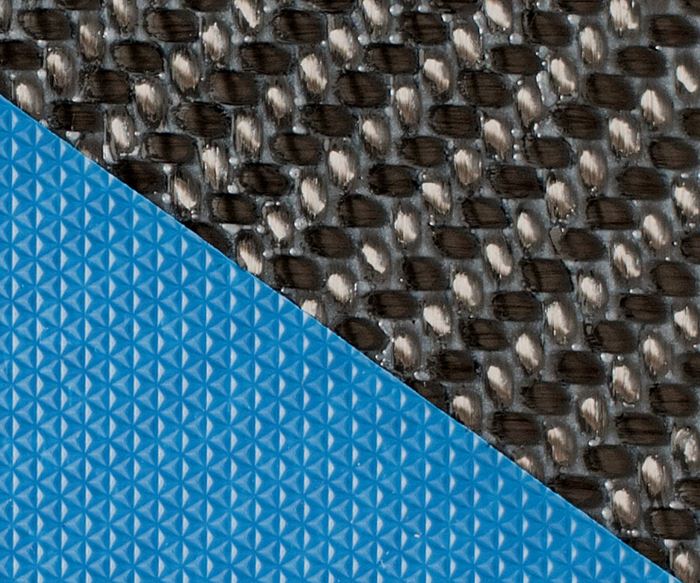

PRF Composite Materials’ RP542-4 is its latest epoxy prepreg system for unidirectional and woven carbon fiber fabrics.

PRF Composite Materials (Dorset, U.K.) introduces RP542-4, its latest epoxy

prepreg system for unidirectional (UD) and woven carbon fiber fabrics. RP542-4 has been designed as an intermediately toughened system to complement the company’s RP542-1 and super-toughened RP549 systems.

According to the company, the system has exhibited excellent tensile, compressive, flexural and interlaminar properties through mechanical testing, and has shown a coefficient of thermal expansion (Tg) of 138°C after curing at 120°C. The onset Tg can reportedly be improved by 20°C to 120°C after postcuring at 140°C for 2 hours. The system has an outlife of 60 days at 20°C. RP542-4 is available on 300-gsm and 600-gsm unidirectional carbon fiber as well as on a variety of fiber types in PRF’s range of high-quality woven fabrics.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

.jpg;width=70;height=70;mode=crop)