RTP Co. expands line of conductive compounds

RTP Co.’s CCX Conductive Masterbatches can be formulated with carbon nanotubes, carbon black, stainless steel fiber or dissipative polymer technology.

The housing for this external computer storage disk was molded from an RTP Co. conductive compound formulated with carbon nanotubes to meet strict ESD protection requirements, and to achieve dimensional stability and low particulation. Source | RTP Co.

RTP Co. (Winona, Minn., U.S.), a global custom-engineered thermoplastics compounder, has expanded its line of conductive compounds to include new CCX Conductive Masterbatches, designed as safe, productive and reliable solutions for environments that are prone to electrostatic discharge (ESD).

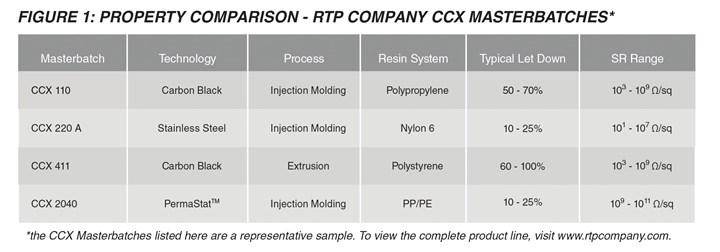

CCX Conductive Masterbatches are available in a variety of resin systems, and can be formulated with one of four additive technologies: carbon nanotubes, carbon black, stainless steel fiber or PermaStat dissipative polymer technology. Figure 1 compares the properties for each material and process.

Source | RTP Co.

Stainless steel fiber CCX Masterbatches are created using the company’s long fiber manufacturing process, and are said to enable the highest level of conductivity, providing EMI shielding for sensitive electronics, colored parts and components, or FDA-compliant applications. Available in most resin systems, they are said to exhibit similar shrinkage and mechanical performance as the unfilled base resin, which makes them suitable for injection molding and compatible with existing molds and tooling.

Carbon nanotube CCX Masterbatches can be used in high-purity applications, and are said to have almost no effect on shrinkage or mechanical properties compared to the unfilled base resin. The carbon nanotubes, when incorporated into a thermoplastic, are said to provide highly uniform ESD protection and/or electrical conductivity at a low loading level.

Carbon black CCX Masterbatches are also reported to have similar isotropic shrinkage, strength and stiffness to the unfilled base resin, and are designed to be an economical method for introducing versatile, high-performance conductivity to a plastic part.

PermaStat CCX Masterbatches are formulated for applications that require permanent antistatic or static dissipative performance. These masterbatches reportedly can be used in most resins with processing temperatures below 520°F (270°C). They provide uniform dissipative performance, full colorability and transparency in some resins, while said to retain or even enhance the impact performance of the base resin. Additionally, they are said to be suited to intrinsic safety applications and can meet the surface resistance requirements of the ATEX directive. They are compatible with injection molding or extrusion equipment.

.jpg;width=70;height=70;mode=crop)