Tepex thermoplastic composites demonstrate fire resistance for EVs

Bond-Laminates’ continuous-fiber-reinforced thermoplastic composite has passed flammability tests for car interiors.

Bond-Laminates’ Tepex continuous-fiber-reinforced thermoplastic composite materials have structures designed to resist fire without flame-retardant additives. This is a result of tests conducted by the Lanxess subsidiary partly in cooperation with external testing institutes.

“The tests also showed that our composites are highly suitable for structural components and housing components in high-voltage batteries for electric vehicles, which, for safety reasons, need to have excellent flame-retardant properties,” says Dr. Stefan Seidel, head of Research and Development at Bond-Laminates. “The materials here present a lightweight alternative to aluminum. They enable cost-effective component solutions thanks to the cost-reducing integration of functions and simple processing in the hybrid molding method without the need for rework.”

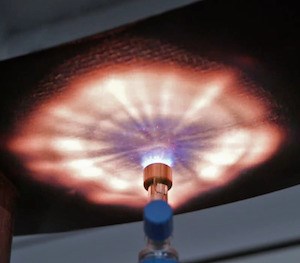

Non-flame-retardant Tepex variants were tested in a fire pan test in which the specimen lies flat over a tub of burning fuel and is exposed to the fire directly for 70 seconds and less directly for 60 seconds. This test is a realistic reflection of the fire situations Tepex might face in typical applications such as underbody paneling components, Bond-Laminates says.

With electric vehicle powertrains in mind, Bond-Laminates has tested the fire behavior of overmolded, polyamide 6-based Tepex. A “HiAnt carrier” was used. This is a U-shaped profile made of Tepex, the inside of which is reinforced with crosswise ribs made of various polyamide 6 types such as Durethan, with or without a flame-retardant package. The specimen is exposed to a 900 °C flame in six positions for between 30 seconds and five minutes, including on the polyamide ribs and areas that have not been overmolded.

“Using non-flame-retardant Tepex with a flame-retardant injection molding material offers a very substantial safety margin for the design of flame-retardant components. We see enormous potential for this material combination to be applied in high-voltage battery components such as housings and partitions, but also in floor plates for inductive battery charging systems,” says Seidel.

Tepex with inherent flame-retardant properties exhibit:

• Fabric structure and high fiber content prevent flames from spreading

• Flame-retardant product variants with UL 94 V-0 classification

• Suitable for use in flame-resistant high-voltage battery components and inductive charging

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.