Thermal processing workflow software effectively monitors composite processing equipment

CAMX 2023: State-of-the-art, user-friendly PCS 2.0 showcased by Walton Process Technologies is an Industry 4.0 process control software for autoclaves, presses and ovens.

With 26 years of industrial software expertise, Walton Process Technologies (WPT, Mansfield, Texas, U.S.) celebrates the fifth year since its launch of PCS 2.0, the modern successor to the company’s proven process control software for composite processing equipment.

PCS 2.0 is said to take the best from WPT’s established solutions to create even more effective tools and insights to illuminate facility-wide process data. Coded with performant and scalable technologies, WPT is able to iterate quickly to meet customer requests and ensure satisfaction. PCS 2.0 runs a local web server to provide convenient and secure access to a user’s data — from any device and any location.

PCS 2.0 control all autoclaves, presses and ovens, in addition to performing automatic part quality inspections. A View Run screen provides users with run data from all cures, past and present. Pre-run warnings show a series of automatic system checks to ensure the run is configured as intended. Active segment metrics show the process controls still waiting to be satisfied and estimated time to completion. A maintenance and calibration mode track an equipment’s downtime due to preventative maintenance, machine down events and calibration. All features are accessible on any mobile device.

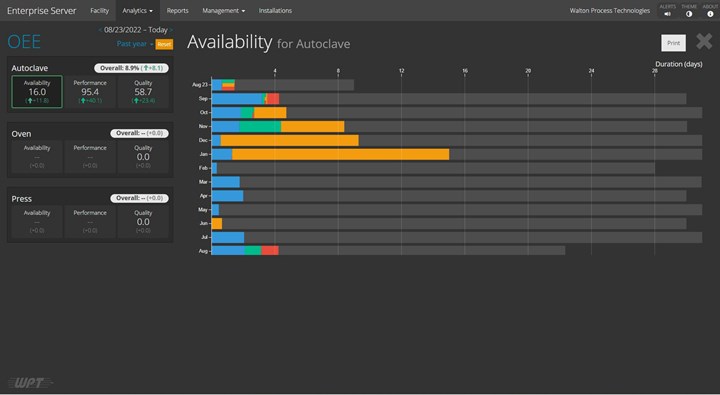

PCS 2.0 can be paired with the optional Enterprise Server, a locally hosted and centralized server for managing all run assets (i.e., users, part, cure and quality specification configurations), running reports and monitoring equipment statuses across the entire facility. This facility-wide monitoring access is convenient, secure and provides live progress of all equipment activities. Analytical features include overall equipment effectiveness (OEE) and queries for detecting performance issues.

The Enterprise Server, built on Microsoft .Net framework, can live on a computer, server, virtual machine or can be housed in an optional cloud hosting environment. The client and server applications use a Microsoft SQL Server. The customer also has the ability to connect to other SAP platforms. Restful APIs enable true IIoT and Industry 4.0 standards.

In addition, the software has been developed with many forms of communication and drivers to connect to existing equipment with older hardware technology. according to WPT. This allows the customer to modernize older autoclaves, presses and ovens without having to upgrade existing hardware, which can be very expensive.

Related Content

-

R&D focus underpins quality gelcoat offerings

CAMX 2024: HK Research strives for innovation and customer satisfaction through meticulously produced polymers, liquid pigments and specialty additives and customer support.

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

One-stop composites manufacturer, distributor

CAMX 2023: FiberGlass Coatings provides B2B and B2C and services to meet fiberglass and coating product needs.