Toray nanoalloy technology develops new flexible and toughened polymer

New polymer combines PA6 with polyrotaxane and retains high thermal resistance, rigidity and strength with a bending fatigue limit that is 15-fold that of conventional polymers.

Photo Credit: Toray Industries

Toray Industries, Inc. (Tokoyo, Japan) announced on Jan 21. that it has created a new polymer that retains the high thermal resistance, rigidity and strength of polyamide 6 (PA6) while delivering a bending fatigue limit that is 15-fold that of conventional polymers. Prospective applications include automotive, appliances and sporting goods.

PA6 resin typically incorporates a flexible elastomer to resist fatigue and optimize the lifespan. The tradeoff, however, is that this lowers PA6’s thermal resistance, rigidity and strength. In order to develop a new materials that offers all of these desirable properties, Toray says it focused on polyrotaxane, a polymer which has a sliding molecular bond, or whose structure moves in response to external forces.

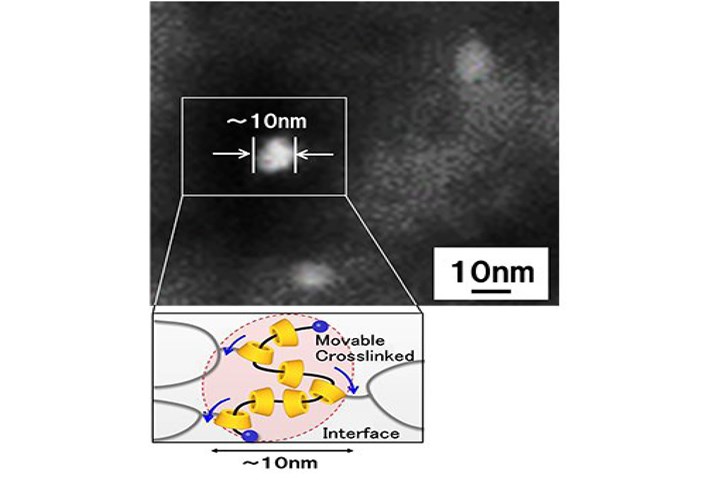

Drawing on proprietary Nanoalloy microstructure control technology, Toray says it maximized the effectiveness of polyrotaxane by dispersing it amongst the 10-nanometer crystals of PA6. The resulting flexible stress-dispersion mechanism led to the creation of the new polymer. Tests at the SPring-8 synchrotron radiation facility in Japan confirmed that the new polymer suppresses changes in the crystal structure of PA6 when subjected to external forces.

Toray looks to initiate full-fledged sample work in fiscal year 2021 while cultivating applications in diverse industrial materials fields.

Related Content

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Composite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.