Search Results

Showing 11 – 20 of 449 results

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Multiple methods advance toward faster robotic welds using new technology for increased volumes and larger aerostructures.

The International Conference and Exhibition on Thermoplastic Composites on Oct. 9-10, 2024 features top speakers and sessions on novel TPC technologies and applications in automotive, aerospace, hydrogen and more.

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Clean Sky 2 HELACS project aims to enable improved recycling of composite components at aircraft end of life.

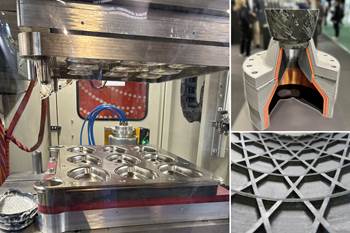

Incorporation of FiberForm advances NIAR ability to convert metallic components to fiber-reinforced thermoplastic versions in cargo aircraft.