Search Results

Showing 21 – 30 of 34 results

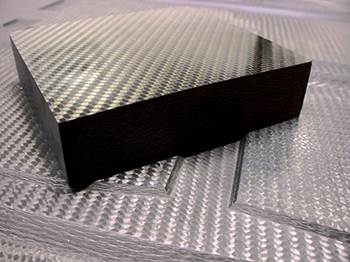

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

MIT evolves liquid biomaterials into a new approach for sustainable engineered composite structures.

This abundant, renewable resource shows promise as an alternative to PAN for low-cost, functional carbon fibers.

Permanent or removable, these hollow thermoplastic cores broaden industry offerings.

As interest grows in composite battery covers and trays, composite materials suppliers work to meet current and future needs of automakers, battery module producers.

Multiple trends support composites advances in this huge but fragmented market.

A demonstration of large-format 3D printing delivers parts for an excavator cab, from CAD data to ready for assembly, in only five hours.

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here's a guide to selection.

Thermoset resin formulators seek environmental benefits as customers demand reduced cost and increased performance.