Search Results

Showing 371 – 380 of 1112 results

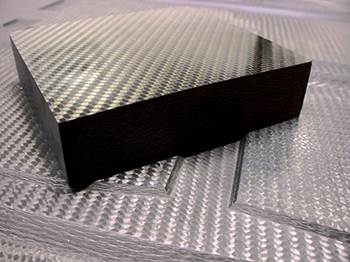

Composite materials are engineered combinations of two or more distinct materials, merging their individual properties to create a new material with enhanced characteristics. Typically composed of a reinforcing phase (like fibers or particles) embedded within a matrix (often a polymer, metal, or ceramic), composites leverage the strengths of each component to achieve superior strength, stiffness, lightness, or other desirable attributes. Their versatility extends across industries, from aerospace and automotive to construction and sports equipment, where their tailored design and exceptional properties offer solutions for high-performance applications.

Recycling in composites manufacturing is an evolving endeavor aimed at addressing sustainability challenges. Unlike traditional materials, composites often pose recycling complexities due to their multi-component nature. However, innovative techniques are emerging to tackle this issue. Methods like pyrolysis, mechanical recycling, and chemical processes are being developed to efficiently recover valuable components from composite waste, such as fibers or matrix materials.

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

There is some hope on the near horizon for reclaiming carbon fibers from the estimated 40 to 60 percent scrap volume that results from the manufacture of automotive CFRP.

Compared to lauan rainforest plywood, INCA’s BioPanels are reported to reduce carbon emissions, waste production and water consumption.

Glass fiber-filled rPET suitable for high performance and structural applications using 3D pellet printing/fused granulate fabrication (FGF).

Frazer Barnes, managing director of ELG Carbon Fibre (Coseley, UK), joins CW Talks: The Composites Podcast to discuss his and his company’s work developing carbon fiber recycling technologies, and the fiber reinforcements that result.

New Toray development holds promise for advanced batteries, gas-separation technologies for fuel cells.

Topics identified for the Tech Hub include composite materials, decarbonization technologies, robotics and automation.

Decommissioned composite wind turbine blades will be recycled into cement production to replace raw material needs, while still enabling a net-positive environmental impact.

Lorenz and IVW collaborate on a sheet molding compound (SMC) that can accommodate sunflower seed shells, reeds and other natural fibers and fillers.

A European consortium is developing a recyclable, sorted fiber composite material made of polyethylene that is suitable for load-bearing components.

.jpg;maxWidth=350;quality=70)