Search Results

Showing 31 – 40 of 91 results

The advantages of building aircraft structures with composites, compared to metal, include light weight, high specific strength, superior fatigue properties, damage tolerance and the absence of corrosion.

Upcoming space event

Explore the technologies, materials and strategies used by composites manufacturers working in the evolving space market. Learn more about CW Tech Days: New Space Applications

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Themes at the forefront of JEC World 2024 included solutions for mobility applications and sustainable materials, technologies and processes for composites manufacturing.

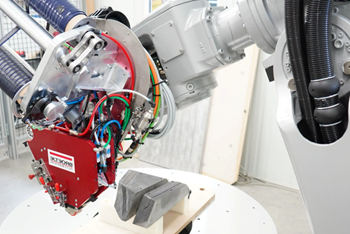

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Mobilized by numerous thermoplastics programs, an innovation center and a new strategic plan, Daher advances its dedication to lighter, stronger aerostructures to meet decarbonization goals.

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

HexPly M51 prepreg and HiFlow HF610F-2 resin add to Hexcel’s delivery of faster cure cycles and thus higher production build rates.

The NCC, alongside partners Loop Technology, Coriolis and Güdel, are on track to deliver dry fiber deposition rates exceeding 350 kilograms/hour, seven times more than standard aerospace rates.

As this year comes to a close, CompositesWorld is taking some time to reflect on what the year held for those in the composites industry. Take a look at the most popular articles of 2021.

With COVID in the past and passengers flying again, commercial aircraft production is ramping up. The aerocomposites supply chain is busy developing new M&P for an approaching next-generation aircraft program.

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.