Search Results

Showing 41 – 50 of 99 results

Polymeric phosphorus-based additive solution brings fire retardance and sustainability to Recron FS fabrics, enabling safe, responsible end-use applications.

The fiber processing and composites manufacturing facility will ramp up INCA’s production of highly refined short and long fibers to substitute increasingly scarce balsa wood in boats, wind turbine blades, rail and automotive.

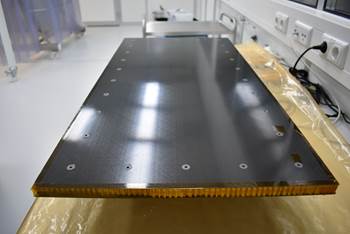

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

The Carbon Fibre Circular Alliance (CFCA) brought together OEMs and technical partners to reclaim short carbon fibers from end-of-life sports equipment, realign into continuous prepreg tapes and remanufacture into new equipment.

Launched SusWIND program aims to establish a viable circular supply chain to tackle the main challenges of legacy and future composite blades in the U.K.

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

Offering liquid and thermoplastic composites molding, LCA-weighted simulation, full testing to validate materials/process data cards, CCC’s digital life cycle approach unites manufacturing, microstructure, part property map and structural analysis.

A 10-partner consortium has received funding for a three-year R&D project aiming at commercialization of sustainable techniques for recycling wind blades.

In part 1 of a two-month column, IACMI chief technology officer Uday Vaidya reflects on the organization’s efforts to reduce the embodied energy of composites.