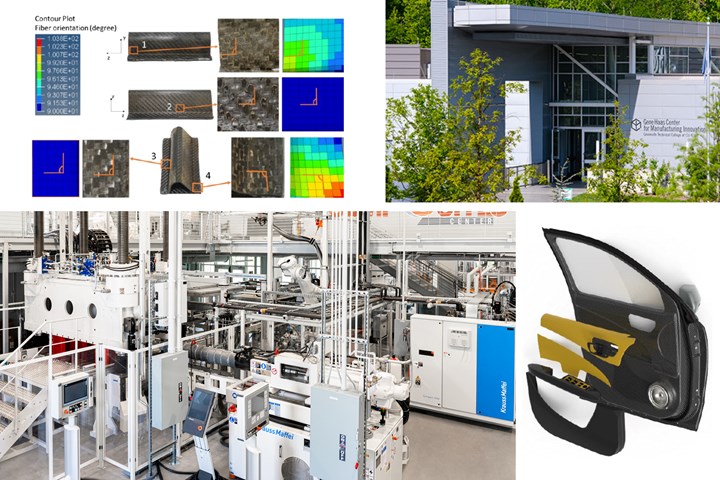

The Clemson Composites Center is housed inside the Center for Manufacturing Innovation (CMI) building (top right) on the 260-acre CU-ICAR campus. It offers expertise in simulation (top left), an integrated manufacturing cell for prototyping composites (bottom left) and is a key partner in the Lightweight Thermoplastic Composites Door project (bottom right). Photo Credit, all images: Clemson Composites Center,CU-ICAR, Clemson University

The Clemson Composites Center (CCC) is a research, innovation and development facility with state-of-the-art equipment and infrastructure dedicated to working with industry to develop, transform and commercialize cost-effective, efficient and sustainable technologies for lightweight composites. It offers services in composites design, materials and product testing and manufacturing. Its advanced research spans multiple disciplines including carbon fiber-reinforced polymer (CFRP) composites, thermoplastic composites, IIoT-enabled composites 4.0, multi-material manufacturing and joining, ultra-lightweight composites and composites informatics.

Clemson University and equipment supplier Krauss Maffei (Munich, Germany) will be hosting an advanced composites symposium, CCC facility commissioning and demonstration on May 26-27, immediately after the SAMPE conference (May 23-26, Charlotte, N.C., U.S.). For more information, contact cuicar@clemson.edu.

Established in 2018, the CCC is operated by full-time engineers and

The Clemson Composites Center (CCC) sits within the Center for Manufacturing Innovation (CMI) building (bottom) on the 260-acre CU-ICAR campus (top).

technicians, offering 6,500 square feet of production space within the Center for Manufacturing Innovation (CMI) building on the 260-acre campus of the Clemson University International Center for Automotive Research (CU-ICAR, Greenville, S.C., U.S.). “CU-ICAR is a public private partnership pursuing automotive research in many different areas including electric propulsion, autonomy, connected vehicles, robotics, vehicle dynamics and sustainability,” explains Srikanth Pilla, director of the CCC. “We are located on the CU-ICAR campus, but we are a stand-alone entity, dedicated solely to composites.”

“Our infrastructure at CCC is uniquely set up to take fundamental R&D and lab discoveries and build these into technologies which can be readily implemented in industry,” says Pilla. “We also offer a center where industries can work with us directly for any kind of prototype or demonstration projects. They can come to us for assistance with design, including how to actualize new concepts or develop part requirements. Small and medium enterprises (SMEs) that don't have a manufacturing entity of their own can also use the CCC as their manufacturing arm, including prototyping, low-rate initial production and small serial production.”

Although the CCC is pursuing research projects from next-gen CFRP parts for aerospace to biobased foams and cellulose nanocrystals for more sustainable, injection molded Class A automotive parts, Pilla notes its four major focus areas are manufacturing, testing, modeling and simulation and sustainability/circularity.

Manufacturing

The CCC’s versatile manufacturing capability includes a unique, integrated composites cell featuring a 1,000-ton press for molding thermoset, thermoplastic or hybrid parts with an impressive array of process choices:

- HP-RTM, C-RTM

- Thermoforming

- Wet compression molding

- Compression molding of prepreg and SMC/BMC

- Injection molding, structural foam injection molding

- Overmolding (insert/outsert molding)

- Polymer-metal hybrid molding

This cell also includes injection, dosing and infrared heating equipment. In addition to the integrated composites cell, the CCC has a lab-scale compounding line for thermoplastics and a pre- and post-fabrication lab for composites materials handling, cutting and post-production machining and finishing.

Testing

“Our testing encompasses the full spectrum of composites mechanical property testing,” says Pilla. This includes environmental cycling and accelerated aging tests as well as dynamic impact testing with high-speed camera recording. The lab also features 2D and 3D digital image correlation (DIC) used to measure and visualize full-field 3D displacement and strain on plastics, composites and metal samples. It also offers differential scanning calorimetry (DSC) and thermogravimetric analysis (TMA) to measure thermal transitions, stability and coefficient of expansion for polymers and composites. “We also use a diffuse laser flash tester to measure the thermal conductivity of materials,” adds Pilla, “and we have rheometry and melt flow instruments to characterize viscosity and viscoelastic properties. We have what is necessary to support the industry’s testing needs and offer testing from coupon level to a sub-component level.”

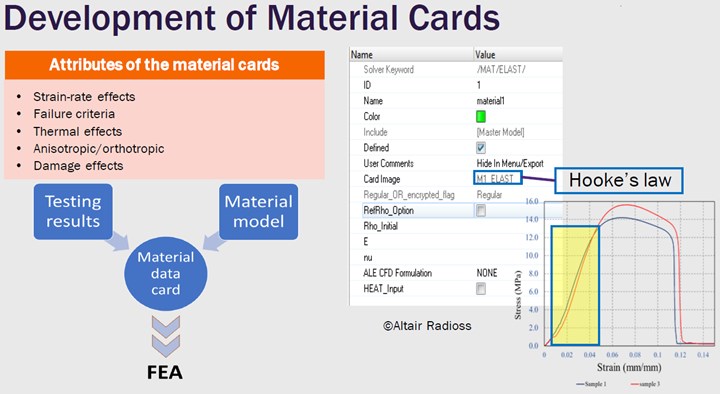

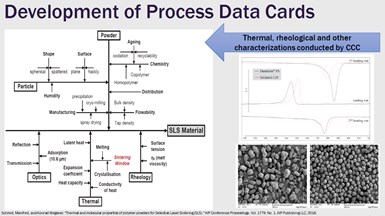

Modeling and Simulation

CCC’s testing capability works hand in hand to support its modeling and simulation, including expertise in the development of material cards for FEA and other analyses. “We are gathering material as well as process data and can also characterize the final product and its performance,” notes Pilla.

He explains that CCC’s modeling and simulation activities range from helping with the design of a component to supporting analysis, including manufacturing process simulations to help understand if the product design can be manufactured efficiently using certain processes. “We have a lot of capabilities for process simulation,” he says. “And then we can also do any kind of microstructure analysis or FEA analysis to understand whether the product and fabricated design meets the performance requirements.”

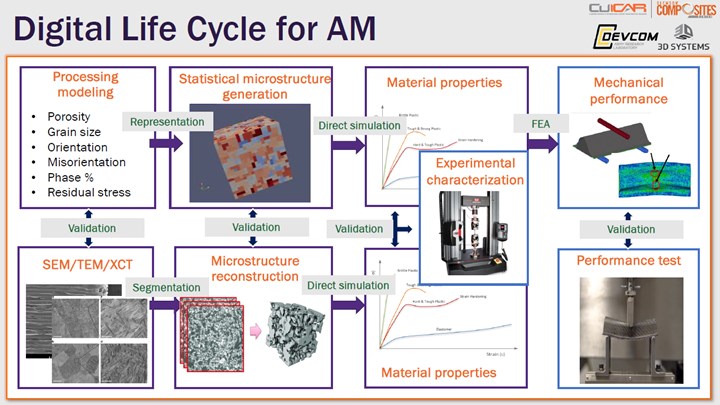

“We can also build a digital life cycle that can virtually simulate the whole product life before you actually invest in product fabrication,” he continues. “For this, we design the product, its entire manufacturing process simulation and microstructure. We can then tell whether the final design is meeting the performance requirements. Once you gain confidence in the product performance, then you can invest in tooling for manufacturing prototypes.”

Digital Life Cycle

“Through our digital life cycle approach,” says Pilla, “we offer a kind of integrated virtual system, where the manufacturing, microstructure, property map and final part structural analysis are all tied together.”

Why is this significant? “Let’s say a company has designed a composite vehicle door and they want to run it through FEA,” says Pilla. “They input the design into the FEA software and then assign the material properties from their library of material data cards that has been constructed from coupon testing. They take the coupon level properties, apply those for the entire design and run the simulation.

But, in our opinion, that is a crude methodology because, for composites, the fiber orientation and alignment in the as-manufactured door are different than in the material test coupons. This is because the door has some complex geometries, and all of the features in the large part are not captured accurately in a coupon.”

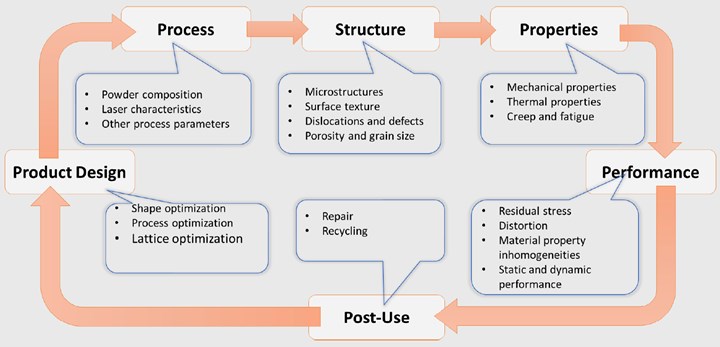

“In our approach, we first run the design through four analysis steps: process, structure, properties and performance,” explains Pilla. “After that, we validate these four different steps at a coupon level and then update all of the models for simulation at a sub-component level. We then validate the sub-component leve simulations and update the models again so we can simulate the final component, as manufactured, with complex geometry. When we do this, we have high confidence that our entire digital lifecycle is now validated and updated to meet the complexity in the final component. We then have a much higher confidence in the results compared to relying only on a coupon level study.”

Digital Life Cycle with recyclability

“So, within our Digital Life Cycle, we look at the process, the structure, the properties and the performance — and all of that is what we're used to seeing,” says Pilla. “But where we haven't seen a lot of simulation is in recycling and then inputting those results back through to the optimization of the product design and manufacturing.” He notes that this ability to simulate repair and recycling is not embedded in the CCC Digital Life Cycle virtual system but is evaluated in an add-on module and then input back into the integrated approach.

“We have what is called an Inverse Design Module, which is outside the digital life cycle domain,” he explains. “Let’s use the vehicle door example again, where the door needs to meet certain federal regulations and metrics. Based on these criteria, there is a certain stress-strain map that the door must conform to in a crash situation. Based on that stress-strain map, we understand how to select the appropriate manufacturing process, and that determines the microstructure, etc. So, instead of going from bottom up, we go from top down — an inverse design process. And when we do this, we can add repair and recycling, where we have materials that are recyclable.” This add-on module takes into consideration the material selection, and for repair, it also takes into consideration the assembly of the part. The CCC currently evaluates several recycling methods, including chemical recycling (solvolysis), thermal recycling (pyrolysis) or simple mechanical recycling.

Digital Life Cycle with life cycle analysis

The CCC has developed a new version of DLC, which is called integrated LCA DLC, where LCA stands for life cycle assessment. “In this version,” explains Pilla, “when we do the material selection, we automatically do lifecycle assessments for those materials in parallel to the DLC being completed. Then this parallel information is fed into the simulation at the performance level. For example, we will investigate material A in terms of LCA and then the entire manufacturing and then these two are basically now integrated. There is also a cost assessment that is done for material A so that we can now evaluate three metrics — cost, performance and environmental impact — between multiple materials. This enables us to decide which material is best, either based on the combination of these metrics, or we can weight one metric over the others. This is an integrated LCA DLC analysis, and it is embedded within our Inverse Design Module.”

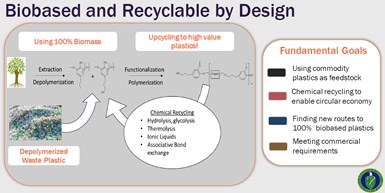

Bio-based and recyclable composites

The fourth focus area at CCC is sustainability and circularity. Although CCC works quite a bit with biobased materials, it also advocates designing materials for recyclability. “This means that you design the materials from scratch with recyclability in mind, so that your components are inherently recyclable at the end of their service life,” says Pilla.

“For example, we make the same polyurethanes that are commonly used in automotive composites, but ours can be chemically recycled at the end of their service life. We achieved this by designing the polyurethane chemistry with embedded bonds that can be readily broken apart during the chemical recycling process. We are designing this at the oxygen and hydrogen-based level groups.” The end result is that the composite materials can be more easily disassembled and reclaimed. The CCC is also making electric vehicle batteries out of more sustainable, biobased materials and looking at nanocellulose additives for foamed composites in ultra-lightweight vehicle components.

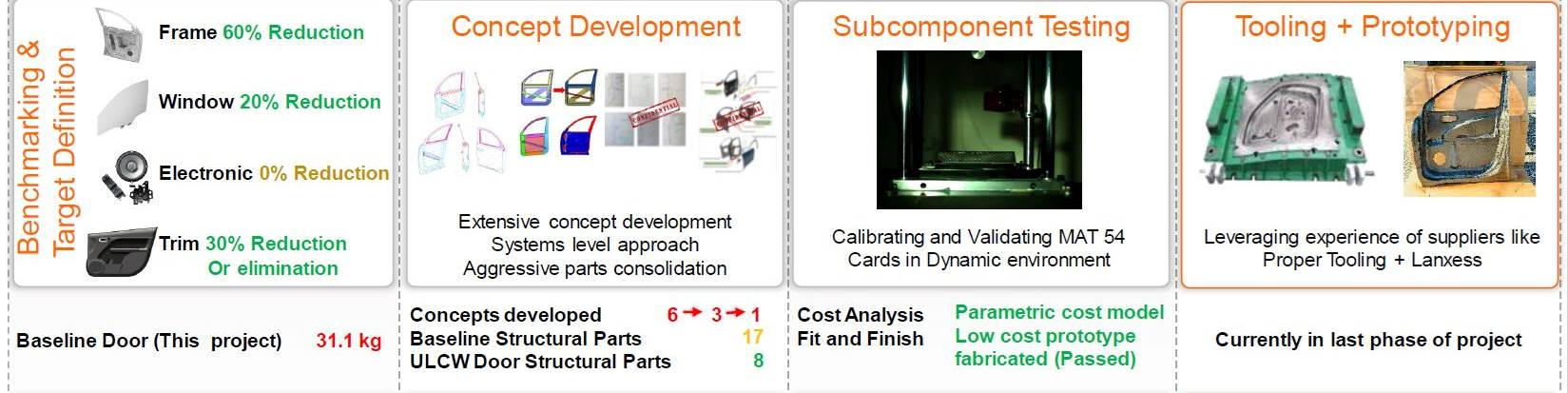

Ultra-lightweight composites door project

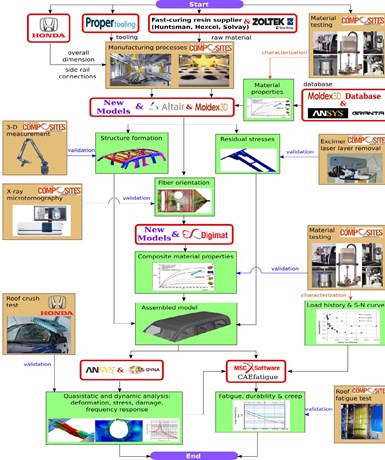

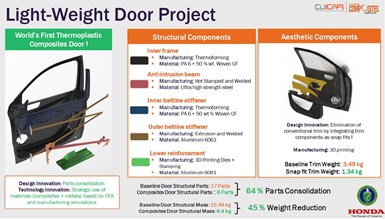

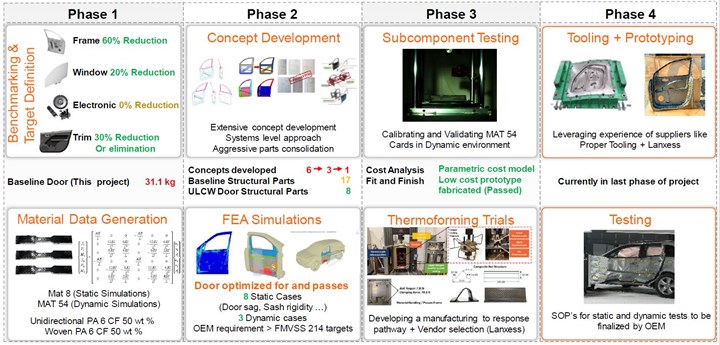

As described in the 2019 CW blog, “Thermoplastic door a first for automotive composites”, this project, funded by the Dept. of Energy, included the CCC and partners Honda North America, University of Delaware (Newark, Del., U.S.), thermoplastics supplier Lanxess USA (Pittsburgh, Pa., U.S.) and Proper Tooling (Warren, Mich., U.S.).

Its objectives included:

- 50% weight reduction vs. metal baseline

(18 kilograms vs. 32 kilograms) - No compromise on performance targets

(e.g., crash, durability, NVH) - Maximum cost increase of $5/pound weight saved

- Scalability to production volume of 20,000 vehicles/year

- At least 95% recyclability per European regulations

The image below shows the work packages completed by CCC. As shown above, the lightweight door retained steel for the anti-intrusion beam and used aluminum for the outer beltline stiffeners and lower reinforcement, but composites were adopted for the inner structure frame (most of the assembly shown above) as well as the inner beltline stiffener. Both used polyamide 6 thermoplastic polymer reinforced 50% by weight with woven carbon fiber. This design reduced the door’s structural mass from the steel baseline of 15.4 kilograms down to 8.4 kilograms (a 45% improvement) and consolidated 17 parts down to 6 (a 64% improvement).

The structural composite parts for the lightweight door were made using compression molding with matched metal molds made by Proper Tooling. Manufacturing trials are scheduled to being on May 16 and the project is to be completed in November 2022. A paper on thermoforming of these components was published in the April 2022 issue of the journal Composites Part B: Engineering.

Related Content

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

Read MoreDesigning an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More