Search Results

Showing 551 – 560 of 1113 results

Composite materials are engineered combinations of two or more distinct materials, merging their individual properties to create a new material with enhanced characteristics. Typically composed of a reinforcing phase (like fibers or particles) embedded within a matrix (often a polymer, metal, or ceramic), composites leverage the strengths of each component to achieve superior strength, stiffness, lightness, or other desirable attributes. Their versatility extends across industries, from aerospace and automotive to construction and sports equipment, where their tailored design and exceptional properties offer solutions for high-performance applications.

Recycling in composites manufacturing is an evolving endeavor aimed at addressing sustainability challenges. Unlike traditional materials, composites often pose recycling complexities due to their multi-component nature. However, innovative techniques are emerging to tackle this issue. Methods like pyrolysis, mechanical recycling, and chemical processes are being developed to efficiently recover valuable components from composite waste, such as fibers or matrix materials.

Adhesive additive technology is reported to make composite parts easier to dismantle, maintain and recycle.

High-end design furniture is 3D printed from bio-based, eco-friendly materials for aesthetic and sustainable home product options.

Staying true to the roots of its racing class, FLOKI 6.5 is built entirely from bio-based/recyclable raw materials without compromising on performance or processability.

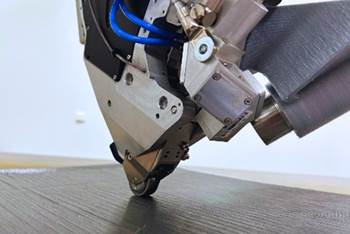

This compact cell brings together 3D printing, AFP and milling aided by a comprehensive software program, further simplifying the manufacture of complex thermoplastic composite aerostructures in the future.

CW interactive webinar will explore refueling stations, conformable tanks, Type IV glass fiber pressure vessels and in-vessel sensors for process and lifetime monitoring.

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Additive manufacturing with bio-based, 100% recyclable feedstocks reinforced with wood can reduce construction time by six months and cut costs by 25-50%

Graduate and undergraduate students interested in sharing their work on innovative thermoset composite technologies can submit abstracts by April 19, 2024, and posters by April 26.

Recently announced composites events news includes new events and speaker abstract deadlines from the ACMA, AIMPLAS, KRÜSS, Polynt-Reichhold and SPE.

Gift your boss, coworker, employees, family members or even yourself this holiday season with one of these 20 composites-related ideas.