Search Results

Showing 1 – 10 of 35 results

Portland State Aerospace Society, incorporating CRP Technology’s GFRP composite materials and SLS 3D printing, sent its CubeSat nanosatellite into low Earth orbit in 2021, where it continues to operate successfully.

CFRP has become key to targeting efforts in reusing components like rocket stages, as well as the development of reusable hypersonic testbeds and spaceplanes, for increasing space commercialization.

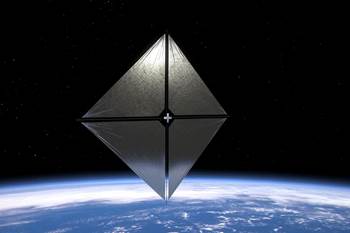

NASA ACS3 system made of flexible polymer and carbon fiber materials has successfully deployed its boom system, shows potential for future space operations.

The CAPSTONE CubeSat is scheduled for launch from Virginia, U.S. in 2021.

The composites-intensive Alpha launch vehicle will be used in NASA missions to deliver payloads such as CubeSats.

GTNANO ANT, validated through multiple Phase I-III SBIR/STTR projects, are compatible with a wide range of composite materials and processes, demonstrating ILSS, toughness and fatigue resistance.

RWC built and delivered solar array substrate panels from trace/lead-integrated skins that enable direct integration with solar cells, saving weight and time.

The carbon nanotube/epoxy combination is being evaluated for the fabrication of mirrors on cubesats for planetary space exploration and Earth observations.

This sidebar to the September 2016 feature story on the emerging commercial space industry focuses on Habitats and CubeSats.

Sunlight-based propulsion system, supported by carbon fiber-reinforced booms, will undergo weeks-long testing to demonstrate and verify its capabilities.