Covestro LLC

1 Covestro Circle

Pittsburgh, PA 15205 US

844-646-0545 | 412-413-2000

covestro.com

About Covestro LLC

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Covestro LLC Supplies the Following Products

- CAD/CAM/CAE design

- Foam core, polyurethane

- Materials analysis

- Other casting resins

- Polycarbonate

- Polyurethane (PU)

- Product design

- Urethane

Editorial, News, and Products

-

Covestro signs investment agreement with ADNOC

Agreement supports ADNOC’s public takeover offer to all of Covestro’s shareholders, all of which will become a foundation for ADNOC’s performance materials and specialty chemicals business.

-

Covestro invests in renovations, technical upgrades to U.S. HQ

Covestro LLC is investing $40 million in an array of modernization and technical upgrades to its Pittsburgh location, aiming to renovate its existing polyurethane R&D facilities and improve equipment and machinery.

-

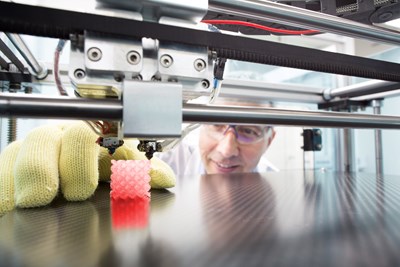

Covestro sells additive manufacturing business to Stratasys

Originally announced in August 2022, the sale includes 3D printing materials solutions, employees, R&D facilities and offices across Europe, the U.S. and Asia.

-

People in Composites: January 2023

Beyond Gravity, Wisconsin Oven, Exel Composites, Corebon, Strongwell, Hexcel, Norco Composites and many others in the industry have announced updates to company personnel.

-

Covestro, Arcesso Dynamics launch solid-surface manufacturing solution Arfinio

First use of reaction injection molding (RIM) on aliphatic polyurethanes enables complex, lightweight and seamless designs and new property combinations.

-

AZL Aachen with 46 industry partners successfully complete multi-material battery casings project

Multi-material solutions, including consideration of composites, open up high potential for cost and weight savings for battery casings, with follow-up projects to come in 2022.

-

SPE Automotive Division names 36 finalists for annual Automotive Innovation Awards Gala

Category and grand award winners selected by the Blue Ribbon judging round Oct. 1 will be announced during the gala on Nov. 10, 2021. Submissions are described below.

-

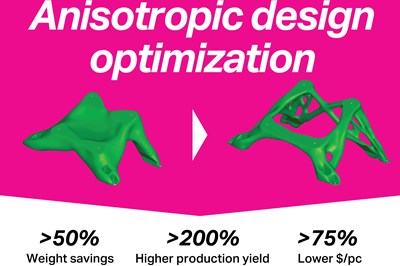

Covestro and ParaMatters develop anisotropic optimization software for composites

Designers and engineers can use the new optimization tool to obtain the most optimal part design based on material deposition and fiber orientation.

-

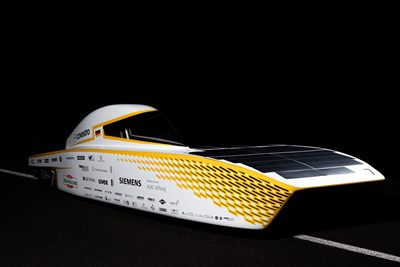

Covestro extends cooperation with Sonnenwagen Aachen team for international solar car races

Covestro to remain the main sponsor until 2023 and fund the development of two new sustainable solar cars for future races incorporating bio-based raw materials and recycled plastics.

-

Resin shortages continue to affect composites supply chain

Power outages caused by mid-February’s U.S. winter storms led to immediate shortages from Gulf Coast petrochemical companies. Fabricators continue to report shortages.

-

New 3dpbm market analysis division presents AM industry study results

Analysis of composites additive manufacturing performed by the new market analysis and consultancy group shows the market generating $10.6 billion in yearly revenues by 2030.

-

Covestro machine developed for direct infusion of polyurethane rotor blades

Covestro’s tailor-made Baulé machine enabled production of a 64.2-meter-long polyurethane turbine blade.

-

Covestro provides sustainable composite material for Toyota electric concept car

Components of the Toyota LQ will be made from a new kenaf fiber-reinforced polyurethane foam composite material.

-

Presidium launches fast-cure, high-strength resin system

Presidium USA is introducing to the composites manufacturing market the RevoTherm line of resin systems that offer low viscosity, fast cure and high strength in finished parts.

-

Thermoplastic composites incorporated into vehicle seatback concept

Covestro’s Maezio carbon fiber-reinforced thermoplastic composites were used to develop a lightweight, sustainable seatback concept for a Chinese car manufacturer.

-

3D filament winding enables vehicle seating concept

Multi-company collaboration uses xFK in 3D and additive manufacturing to develop an ultra-lightweight seat for hypercars and future mobility platforms.

-

BÜFA to distribute Covestro's Maezio UD tapes

Covestro enters into a distribution agreement granting BÜFA Thermoplastic Composites distribution rights for Maezio thermoplastic unidirectional) tapes.

-

Tuning the running shoe

Continuous fiber-reinforced thermoplastic composites enable high-performance athletic shoe components.

-

Continuous fiber-reinforced thermoplastics data added to CAMPUS database

The new data, which will be released in October, is the result of an ongoing material standardization and characterization effort led by German reinforced plastics company AVK.

-

Covestro delivers first order of polyurethane resin for wind blades

Covestro’s polyurethane infusion resin was developed to help the wind power industry meet the growing demand for longer wind blade designs.

-

AZL production system wins JEC Innovation Award

AZL’s UItra-Fast Consolidator Machine, winner of the JEC Innovation Award 2019 for Industry/Equipment, will be the subject of further research into commercialization of the machine.

-

Covestro and EconCore collaborate on FST-optimized honeycomb core and panels

The collaboration aims to optimize the FST performance of honeycomb panels for public transportation applications, including railway and aerospace.

-

Covestro highlights convergence of technology and composite materials at Consumer Electronics Show

Supplier of Maezio continuous fiber thermoplastic composites will host wearable tech and gaming accessories companies at CES 2019.

-

Pultrusion picks up speed in automotive applications

Pultrusion is one of the most cost-effective processes for manufacturing high-volume composite parts.

-

Fast manufacturing of tailored composite blanks

AZL and 12 partner companies have completed a research project to develop a new machine prototype allowing increased speed for manufacturing tailored composite blanks.

-

Covestro launches Maezio continuous fiber thermoplastics

Covestro (Leverkusen, Germany) has trademarked its continuous fiber-reinforced thermoplastic (CFRTP) composite materials as Maezio.

-

SPE ACCE 2018 preview

Mobility composites are expected to draw an international crowd to this annual Motor City gathering.

-

Pultruded composites market growing, says EPTA

The European Pultrusion Technology Association (EPTA, Frankfurt, Germany) has published an in-depth report on its highly successful 2018 conference, held in Vienna on March 1-2, 2018. The 12-page document, World Pultrusion Conference 2018: Attractive Long-Term Prospects for Pultruded Composites, is available to download from the EPTA website.

-

Continuous fiber thermoplastics are smart for world’s largest appliance manufacturer

Haier uses Covestro CFRTP in Casarte line of “smart” air conditioners

-

Covestro to provide materials to “Sonnenwagen Aachen” team for solar race

The material manufacturer supports the development of a solar-powered electric car with material donations, technical service and as a gold sponsor.

-

Polyurethane’s processing speed, properties enable bigger blades

Decade-long development effort reaches key wind energy cost-reduction milestone using epoxy-besting infusion resin.

-

Cored glass/PU speakers, tabletops impress

Sandwich panels provide music, sound masking sans weight.

-

Covestro is working on housing for refugees in Germany

The model house in Bergisch Gladbach, Germany is made of self-supporting prefabricated elements with Covestro’s polyurethane core.

-

Cooperating on new-generation ground transport

CompositesWorld's editor-in-chief Jeff Sloan shares his observations about the mixture of excitement and anxiety about the future of composite in the auto industry on display at the recent Thermoplastics Composites Conference for Automotive (TCCA), held in the Detroit suburb of Novi, MI, US.

-

Covestro kicking the tires on polycarbonates for automotive

Although development work has only just begun, the company's Makrolon polycarbonate, in a carbon fiber-reinforced composite, is proving highly impact resistant and offers a Class A surface.

-

Covestro helps produce Asia’s first rotor blade made from polyurethane

The 37.5m-long rotor blade was fabricated with a special polyurethane infusion resin from Covestro and glass fiber mats from Chongqing Polycomp International.

-

Ushering in a new era for windows … and more

Superlative stiffness and thermal efficiency could make this highly glass-filled pultruded polyurethane insert a construction industry go-to material of choice.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

What do PU/carbon spars and the Valencia lighthouse have in common?

Saertex reinforcements, infusion, speed of fabrication and long life.

-

Form + function = Classy chassis

Sandwich-composite chassis components double as structural and styling elements, reducing cost of ownership.

-

Solar Impulse 2: Pulse on the future

Not yet through their ‘round the world flight, this superlight solar plane’s airframe-proven materials are already destined for higher callings.

-

Thermoplastic honeycomb cores: Tough insulated sandwiches

Foam-filled nylon/polyester fabric yields sandwich panel cores with excellent mechanicals, durability, thermal insulation.

-

Green resins: Closer to maturity

As more players approach the market, R&D expands, but overall market growth in the composites arena is still slow but steady.

-

CAMX 2015: Automotive, military innovations and on-floor demos

ACMA’s and SAMPE’s second combined event featured plenty of new products and thought-provoking conference sessions for the composites industry.

-

Opportunities for composites at AIA 2015

Key trends and new products on the floor at this year's American Institute of Architects show.

-

Pultruded polyurethane pallets

Composite solution transforms wooden consumable into profit-generating asset.

-

CAMX 2014 show report

Bigger, better and more inclusive than any previous U.S. composites trade event, the inaugural show turns North American eyes forward to the future.

-

Architectural composites: Rising to new challenges

In North America, Europe, the Middle East and Down Under, architects and engineers are finding composites are a good fit in groundbreaking applications.

-

Pultruded window: Glass/polyurethane prototype wins award

Deceuninck Group NV (Hooglede-Gits, Belgium), is at the forefront of composite window frame design and innovation, as evidenced by its recent award for a large, prototype window designed to open like a door.

-

CAMX offers unprecedented new product access

CAMX 2014, Oct. 13-16 in Orlando, Fla., promises to be North America's largest ever composites trade show and conference. As a result, exhibitors are coming to the event with a wide array of new and existing materials, machinery, software and technology designed to help make composites fabrication faster, easier and more adaptable. CompositesWorld has been gathering information from CAMX exhibitors about what they will be featuring and introducing in their booths. This week's CAMX newsletter offers a preview of some of what you will find on the show floor.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Processing within the PUR cure window

Composite Spray Molding enables volume production of fiber-reinforced polyurethane sandwich structures for auto interiors. Are Class A exterior parts next?

-

Business and busy-ness

CT editor-in-chief Jeff Sloan returns for JEC Europe 2014 in Paris with observations about several intriguing composites industry trends.

-

LFI process: Molding strong and attractive spa enclosures

Dynasty Spas (Athens, Tenn.) finds a composite alternative to wood hot tub surrounds in a polyurethane (PU)-based long fiber injection (LFI) solution implemented by Romeo RIM Inc. (Romeo, Mich.).

-

Pultruding polyurethane: Sheet pilings break boundaries

High-pressure pultrusion process creates polyurethane composite sheet pile system with the strength and stiffness to compete with steel.

-

The evolution of infusion

As resin infusion continues to infiltrate composites, fabricators across the market spectrum drive materials and process developments in pursuit of process control.

-

Pultruded windows: Rising high?

New pultrudable glass fiber/resin formulations enable window manufacturers to break in to commercial architecture and build market share in residential construction.

-

COMPOSITES 2012 Highlights

As ACMA’s annual conclave convened in North America’s gambling capital, show exhibitors and attendees placed their bets on better days.

-

SPE ACCE 2011: Growing again

The Society of Plastics Engineers’ 11th conference on automotive composites fields a top slate of speakers and attracts its largest crowd.

-

Small wind gets big

Massive growth, complex blade designs reopen challenging market in wind energy niche.

-

COMPOSITES 2011 Product Showcase

Composite Technology magazine's review of the goings-on at COMPOSITES 2011, this year’s edition of the American Composites Manufacturers Assn.’s (ACMA, Arlington, Va.) annual trade show and conference (Feb. 2-4, Greater Ft. Lauderdale Convention Center, Fla.).

-

Interior innovation: The value proposition

OEMs and Tier suppliers ask materials and molding processes to go “green” and do more for less.

-

Composites 2010 Product Showcase

The ACMA’s Las Vegas exhibition reflected an industry in recovery.

-

Structural polyurethanes: Bearing bigger loads

The versatile polymer shows new strength (and other advantages) in pultrusion and core materials applications.

-

CNTs ride a rising tide of nanotech optimism

Dr. Louis Pilato offers facts, figures and comment on the growing utility of carbon nanotechnologies in composites applications.

-

The key to CNTs: Functionalization

An emerging supply base is integrating carbon nanotubes into commercial products that enable composites manufacturers to optimize part performance.

-

Composites fuel growth of fuel cell technology

Composite components in hydrogen fuel cell systems help handle higher heat and reduce stack size.

-

On the waterfront: Composite marine piles build on success

Composite sheet pile competes against heavy-gauge steel while composite round piles enhance their position in the market and target wider acceptance in structural applications.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

COMPOSITES+POLYCON 2009 Showcase

Despite the deepening recession, composites pros returned to the show in its new time slot to explore the wealth of products and services collected here.

-

Resin systems update: The greening of thermosets

Thermoset resin formulators seek environmental benefits as customers demand reduced cost and increased performance.

-

Polyurethane long fiber technology (LFT) replaces wood in spa surround

To many consumers, the thought of a relaxing soak in a hot tub is mighty appealing — but the thought of spa maintenance, particularly replacing rotted wood in the spa's cabinet-like enclosure, probably isn't. For spa manufacturer Clearwater Spas (Woodinville, Wash.), that reality and the fact that building decorativ

-

Composites Polycon 2007 Showcase

Tampa show attendance is up despite slow economy. ACMA reschedules 2008 show.

-

JEC Composites 2007 Product Showcase

This year’s Parisian exhibition provides key evidence of the composites industry’s unprecedented breadth and technical sophistication.

-

Multishell process streamlines intake manifold

Mann + Hummel Automotive Inc. (Bloomfield Hills, Mich., U.S.A.) recently reengineered its production process for the air intake manifold on General Motors' four-cylinder, 2.2-liter Ecotec engine, replacing lost-core molding techniques with faster, less expensive "multishell" technology. Mann + Hummel now injection