Anisoprint

9 avenue des Hauts Fourneaux

Esch-sur-Alzette, L-4362 LU

7 495 142 57 31

info@anisoprint.com

anisoprint.com

About Anisoprint

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Anisoprint Supplies the Following Products

- 3D printing

- Continuous fiber/thermoplastic resin

- Continuous fiber/thermoset resin

- Fused deposition modeling

- Large format

- Other additive manufacturing

- Small format

Editorial, News, and Products

-

People in composites: November 2024

Take a look at this month’s new hires and promotions in the composites industry from Exel Composites, Thermwood, Volocopter, Anisoprint, TPI Composites and SGL Carbon.

-

Anisoprint opens office in China, scales up continuous fiber 3D printer production

With a new location in Shanghai, and a shift in management roles, Anisoprint is looking forward to rapid growth in Chinese, European and U.S. markets, further aided by funding rounds.

-

Anisoprint expands global presence with Shanghai office

New office located in the Additive Manufacturing Technology Centre enables Anisoprint’s expansion into the Asia-Pacific region.

-

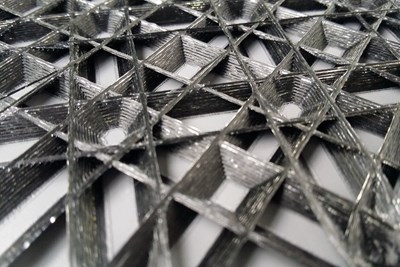

Drawing design cues from nature: Designing for biomimetic composites, Part 2

As biomimetic design continues to inform composites manufacturing, technologies like 3D printing, tailored fiber placement, braiding and filament winding prove strong candidates for making these structures a reality.

-

Anisoprint R&D team begins 3D printing center at Jacobs University Bremen

Established research environment to comprehensively upgrade CFC technology, explore new composites methods, formulations and designs.

-

Drawing design cues from nature: Designing for biomimetic composites, Part 1

Biomimicry is an interdisciplinary methodology that can inform composites design and manufacturing via use of more effective and sustainable materials, structural fabrication and technological practices.

-

Anisoprint partners with Jacobs University, SIT to establish composite 3D printing ecosystem

On-campus continuous fiber 3D printing based in Bremen, Germany, fosters research, education and technology transfer through materials development, process and design method improvement.

-

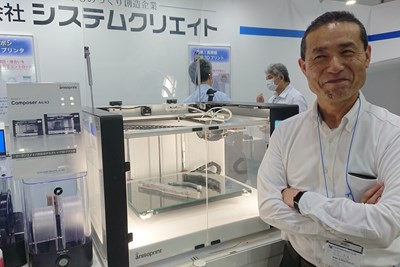

Anisoprint expands global presence, announces exclusive partnership with Systemcreate

Systemcreate is a technology provider that will now exclusively distribute Anisoprint’s continuous fiber coextrusion technology and Composer system in Japan.

-

Anisoprint signs MOU for space-based continuous fiber 3D printing

Continuous fiber co-extrusion (CFC) technology capacities in orbit and for the deployment of additive manufacturing have been demonstrated and validated.

-

Anisoprint enters North America Market with distributor Top 3D Shop

The continuous fiber 3D printer startup will be introducing desktop and industrial anisoprinting solutions, Composer and PROM IS 500, to a new market, beginning at RAPID + TCT 2022 in May.

-

3D printing on the moon: Anisoprint chosen for Start-up Space Program

During SSP, Anisoprint will work to develop composite fiber 3D printing in close-to-zero gravity conditions.

-

Anisoprint launches Clear PETG, CFC PETG for continuous fiber 3D printing

Anisoprint provides Composer 3D printer users and novice customers a new formulation material that produces stable and reliable quality results.

-

Anisoprint introduces industrial 3D printer, invites beta users

PROM IS 500, the company’s large industrial 3D printer to date, is capable of using both high-temperature polymers and fiber-reinforced composites, with adjustable manufacturing volumes and flexible fiber trajectories.

-

Anisoprint, Bosch Rexroth join forces for industrial continuous fiber AM capabilities

Anisoprint’s first generation of industrial printers, PROM IS 500, is powered by Bosch Rexroth’s MTX, a tried-and-proven CNC system for industrial 3D printing technologies.

-

Anisoprint continuous fiber co-extrusion technology powers lunar rover vehicle

Carbon fiber-reinforced wheel mount and control arm design reduces lunar rover weight to as low as 24 and 64 grams, respectively.

-

Anisoprint, Additive Flow launch full-scale topology optimization software for composites

Additive Flow’s FormFlow software enables users to optimize geometry smoothly through all phases of the design process. The tool is compatible with Anisoprint’s slicing software, Aura, for composite 3D printing.

-

Anisoprint launches Aura 2.1 slicing software for continuous fiber 3D printing

New features include “masks” giving users greater control over fiber reinforcement in an easy-to-visualize manner.

-

Skoltech optimizes pultrusion process productivity

The institute analyzed the influence of pulling speed on the structural characteristics of L-shaped profiles, analyzing the interconnection between a variety of characteristics.

-

Anisoprint launches 3D printer for continuous fibers

The Desktop Anisoprinting package comes with tailor-made plastic filament materials, verified printing profiles and a comprehensive training course.

-

3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

-

3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

-

Composites suppliers, fabricators respond to coronavirus

Companies across the composites industry supply chain share how the COVID-19 pandemic is affecting their businesses, and how they are available to help.

-

Composite 3D printing allows damage detection in aerospace and construction

Using Anisoprint 3D printers, a materials research center in the Netherlands has developed 3D-printed composite parts with self-sensing functionality.

-

Anisoprint launches ProM IS 500 industrial 3D printer

ProM IS 500 is said to be the first industrial printer for continuous fiber-reinforced high-temperature plastics.

-

Anisoprint, Polymaker collaborate to enable flexibility in composite 3D printing

The combination of Anisoprint’s 3D printing systems and Polymaker’s plastics offers a range of mechanical and chemical properties for composite part production.

-

Advancing additive manufacturing to exploit anisotropy

Anisoprint posits continuous fiber composites, not metals, as the material for optimized AM structures.