Biomimicry is shaping sustainable design and innovation in a variety of fields. Burrs (top left) inspired Velcro, the kingfisher (top right) informed the design of Japan's famous bullet train and is aiding in channeling incoming wind for turbine blades, takeaways from the mantis shrimp (bottom left) are producing more durable materials and an office complex in Zimbabwe has an internal climate control system originally inspired by the structure of termite mounds (bottom right). Photo Credit: Getty Images.

Bio-inspired designs, supported by nature’s 3.8 billion years of evolution, have demonstrated their advantage in functionalized materials and complex, optimized structures. They are particularly useful in the field of composites manufacturing, where properties such as stiffness, damage tolerance, fatigue resistance, electrical conductivity, self-healing and bonding, just to name a few, are often sought after but not always easy to combine. There are examples, however. Think of wind turbine blades with serrated leading edges imitating a whale fin’s tubercles for improved aerodynamics. Or the sharklets on the wings of most commercial aircraft today, inspired by dorsal fins on the Great White shark.

Humans have taken design cues from nature for thousands of years. Leonardo Da Vinci’s early flight schematics which led to the invention of the parachute, Velcro and bullet trains are a few examples of bio-inspired, human-made structures and parts that have spanned the ages. It wasn’t until the late 1960s, however, that the concept of biomimicry was coined by American academic and inventor, Otto Schmitt. It was further popularized by Janine Benyus in her 1997 book, “Biomimicry: Innovation Inspired by Nature.” Benyus is also co-founder of the Biomimicry Institute (Missoula, Mont., U.S.) and the bio-inspired consultancy Biomimicry 3.8 (formerly the Biomimicry Guild).

Biomimetics, or biomimicry, is generally defined as the design and production of synthetic materials, structures and systems that are modeled on biological entities and processes. While some definitions portray biomimicry as a way to “mimic” or “copy” nature, its true intention is emulation — using structures observed in nature to inform and improve man-made products. There is also the practice of applying biological materials (think bio-derived natural fibers) into synthetic systems to achieve biomimetic properties.

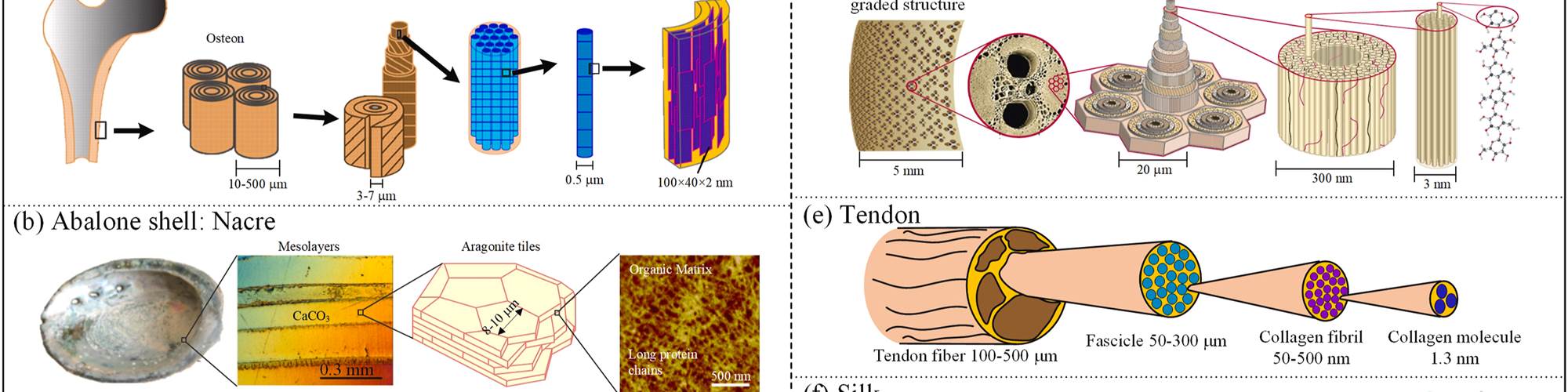

Hierarchical structures of bone, nacre, a crab carapace, bamboo, tendon and silk. Photo Credit: Reprinted from Composites Science and Technology, Vol 214, 2021, 108970, Yuli Chen,Yong Ma,Qifang Yin,Fei Pan,Chaojie Cui, ZuoqiZhang, Bin Liu, “Advances in mechanics of hierarchical composite materials,” p. 2. Copyright 2007 with permission from Elsevier

As an interdisciplinary methodology, biomimicry can be and has been applied in many fields, particularly because of the sheer number of diverse and complex biological systems available. It should come as no surprise then that the composites industry has its own hand in this field. Much found in nature already consists of the marriage between two or more constituent materials — such as wood and insect cuticles — making fiber-reinforced composites a good fit for biological emulation.

In this article, CW presents a few case studies that highlight how biomimicry is being applied to composite materials design. Part 2 of this feature, which will appear in an early 2023 CW issue, will delve further into current and emerging composites manufacturing processes inspired by nature’s production of complex components and structures.

Considerations when designing for biologically informed concepts

Nature, in many cases, presents us with materials that are anisotropic, says Fedor Antonov, CEO of Anisoprint (Luxembourg). “Thus, they are like many fiber-reinforced composites, having different properties in different directions. Structures like wood, fly wings and certain water lily pads have developed elegant, load-optimized structures in response to their environment. And what we see in nature are living tissues, living materials … all of which have actually developed into multiscale hierarchical composites.” Here, Antonov refers to natural structures that consist of fibers like cellulose and collagen (a protein), but are organized in different directions at each geometric scale, from nano to macro, in order to achieve a high level of performance and/or multifunctionality in an efficient way. “From the point of view of nature,” explains Antonov, “where everything is governed by the principals of minimum energy, it doesn’t make sense to create structures that are heavy and require a lot of it [energy].”

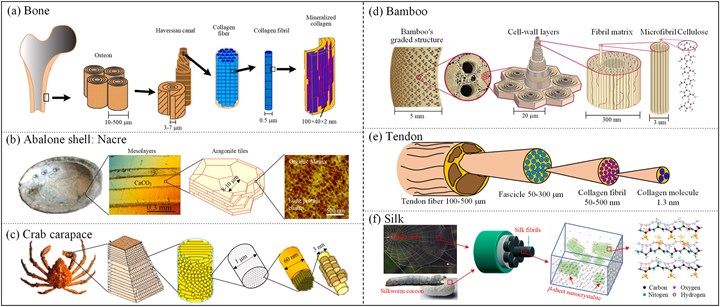

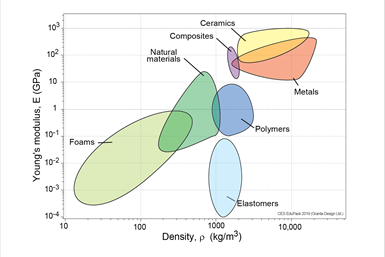

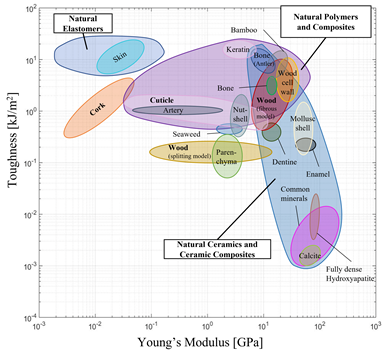

There are a few distinct differences that set apart the design strategies of synthetically engineered materials, like composites, and natural materials. The construction of biological structures is limited to the resources immediately available — lightweight elements such as hydrogen, carbon, nitrogen, oxygen, phosphorous and sulfur — whereas engineered materials have a wider range of elements to choose from. While the natural conclusion to draw from this is that more variety means more capabilities to emulate biological designs and processes, in reality, it can turn into a hindrance because engineered materials are not always able to use certain elements in the same way. Nature also does not often have access to high-temperature/high-pressure processing techniques to produce its structures, at least not quickly (coal and diamonds require millennia). Rather, unlike synthetic materials processing, biological structures are created under mild conditions (ambient temperatures and pressures). These considerations often affect human emulation of the hierarchical structures found in nature.

Whereas humans strive to build stiff and strong, long-life composite structures that resist damage, the elements and processes used by organisms — organized more for survival and reproducibility — actually allow and control damage through stable crack propagation and/or self-repair mechanisms. This is not to say that nature is more simplistic — rather, it makes maximum use of available materials to create astonishingly complex structures and systems with unique mechanical, thermal and/or optical properties using minimal energy and resources. This is indeed an approach to be emulated in composites’ current quest for improved sustainability.

Ashby diagram comparing Young's modulus versus density in a range of natural and synthetic materials (top) and Ashby diagram comparing the toughness and Young’s modulus of natural materials (bottom). Photo Credit: Chart created using CES EduPack 2019, ANSYS Granta ©. Copyright 2020 Granta Design (top), Dr. Lorenzo Mencattelli, “Learning from nature: Bio-inspiration for damage-tolerant high-performance fibre-reinforced composites” (bottom)

The way in which materials are made, naturally or mechanically, also affects design. Nature is governed by the simultaneous growth of the material and the organism through self-assembly, a process in which a disordered system of components forms an organized structure/pattern according to specific, local interactions between each component. Moreover, even after production, these structures are able to remodel and adapt their hierarchy according to environmental changes. Plants, for example, are able to structurally adapt mechanisms related to water storage, shade and protection against predators, depending on the temperature of their habitat.

Alternatively, engineers must select a material and then fabricate the part according to parameters set forth in the design, and the structure must meet all environmental stresses throughout its lifetime without changing. The demands of the engineer’s production environment are also different; nature is not concerned about rate, cost and production volume the same way as industry.

Emulating hierarchical design

Hierarchical design, referenced above, is common in nature. It involves an arranged system of distinct tiers from the nano to macro level that each provide their own series of functions

Even with this example, our understanding of hierarchical composites is still in its early stages. It still represents an area where our lack of maturity in composites design compared to nature affects humans’ ability to apply biological design principles.

For example, “When you start to make high-performance composites, the basic building block you have is a carbon fiber, which is seven microns,” says Kunal Masania, an associate professor in additive manufacturing of biologically inspired composites at Delft University of Technology (TU Delft, Netherlands) and founder of the Shaping Matter Lab. “From there you can change the design by orienting them any way you want, filling in with resin … but natural materials, they’re working on a nanometer scale, so it’s three orders of magnitude smaller.” Masania says nature tends to work at this scale due to the biological processes that drive production, as the building blocks are made from living cells.

Something like the architecture of wood or bone, while molecularly simple, is more complicated structurally, and thus, still difficult to emulate. “Wood fibers, which are cellulose fibers, are hollow,” he says. “The fibers go in the general direction of stresses and also transverse to the wood grain. So you have primary wood fibers, but you also have fibers that connect all across, and all of the fibers have little holes in the cells called ‘pits’ which connect to each other. Their whole structure is completely interpenetrated, and to copy that is a great challenge.”

The Shaping Matter Lab is an interdisciplinary research group in the Faculty of Aerospace Engineering at TU Delft that focuses on three key areas: Bio-inspired composites (i.e., applying natural design principles to create synthetic materials); biologically fabricating composites from raw materials such as living cells and biomaterials; and digital fabrication of hierarchical composites — using data to inform additive manufacturing (AM) processes.

“For the past 50 years, we [the composites industry] were trying to figure out how to make them [composites] more understandable, more reliable,” Masania says. “Now, what’s becoming more important is thinking about end of life, reuse and making composites more circular in addition to adding more life-like functionality.”

To realize biologically fabricated composites, Masania’s team uses existing bulk natural materials such as wood or natural plant fibers to create semi-finished products that can then be processed into structural composites. He says that through this practice, composites have been made that have stiffnesses of up to 70 GPa and strength up to 600 MPa, “better than conventional metals and glass fiber composites and much more sustainable for the future.” Application-ready examples can be found through Bcomp’s (Fribourg, Switzerland) use of flax natural fibers in automotive parts and Bambooders’ (Amsterdam, Netherlands) sustainable approach to bio-based technical fibers made from bamboo.

Bottom-up assembly, top-down shaping

The Shaping Matter Lab also takes a bottom-up approach, beginning with basic building blocks and letting nature inform the structure of the materials. Constantly motivated by a focus on light weight and strength, Masania has studied the hierarchical complexity of materials like nacre, bone, wood and spider silk.

“In bone [for example] you usually have a solution of ions which are captured into a cell, metabolized in a process called biomineralization and these precipitates are deposited as mineral tissue additively,” Masania points out. “The same thing is true in a plant cell. In a plant cell, you will see a cellulose synthase complex, which is an enzyme that produces cellulose which is also deposited layer by layer. What is always common is this bottom-up assembly on a nanoscale level combined with top-down shaping of the cells.”

Masania and his team combine bottom-up self-assembly with top-down shaping using AM. In addition to providing key advantages compared to some other conventional composites manufacturing methods — “complexity for free,” short lead times, reduced processing steps and less waste — the AM fabrication process also seems to fit the bill when it comes to biomimicry, because nature’s building strategy often is AM.

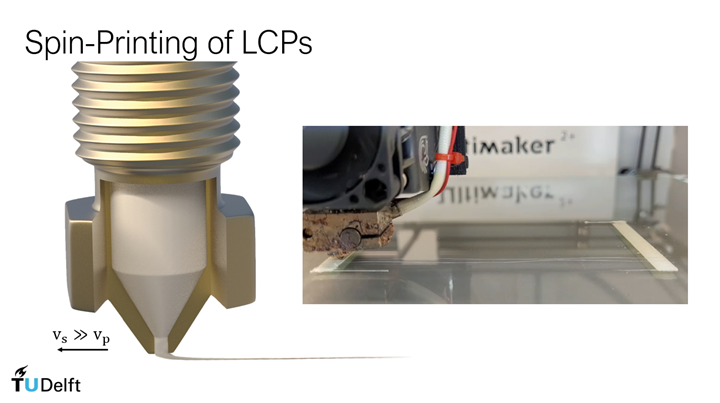

Spin-printing is a fused filament fabrication (FFF) 3D printing method demonstrated here using a thermotropic liquid crystal polymer (LCP) that undergoes molecular alignment during printing. The process involves three steps: printing (the molten polymer), transition (from print to spin) and spinning (of the fibers in the air). Photo Credit: TU Delft

One project that exemplifies this approach was aimed to combat the weakness and low stiffness of polymers using extrusion-based 3D printing. Specifically, spin-printing — a fused filament fabrication (FFF) printing method — was used to exploit directed-assembly and self-assembly of liquid crystal polymers (LCPs) to study the role of anisotropy and porosity and apply these microstructural designs to large structures.

Hierarchically structured, LCPs are very basic molecularly and are locally arranged in an isotropic orientation. “They have a very special trick to them that was established in the ‘80s,” Masania explains, “that when you apply heat to thermotropic LCPs, and you apply shear or elongational stresses, you’re able to molecularly orient the materials. So, we were able to take a material which has similar properties to traditional polymers and through the hierarchical structure and orientation in 3D printing we were able to elevate the mechanical properties. This was astounding because it’s only a polymer, but just by molecular alignment, we can get something which is outperforming glass fiber composites by a lot in terms of strength and it’s about 10 times stiffer and stronger than PEEK [polyetheretherketone].”

Moreover, in combination with the shaping freedom of 3D printing, the self-assembling polymer enables engineers to follow stress paths in objects explicitly, such as to reinforce holes. For example, the open-hole strength using the self-assembling, 3D-printed polymer is reported to be around 370 MPa, with stiffness of 25-30 GPa compared to the relatively low strength and stiffness of the original isotropic material. The technology is now being commercially exploited by startup NematX AG (Zürich, Switzerland) for a range of functional parts for industrial, aerospace and medical applications.

A similar investigation into AM was done at Tsinghua Berkeley Shenzhen Institute (Berkeley, Calif., U.S.). Using graphene as a model building block, the lab successfully fabricated multiscale structures with tailorable features spanning seven orders of magnitude in size — from nanometers to centimeters — via a 3D-printed, template-directed assembly method. Specifically, digital light processing (DLP, a vat polymerization-based 3D printing technique) was used to customize the structure at the meso- and macroscale, and self-assembly was used to tailor the structure’s nano- and microscale structures. This careful structure control at different scales produced a material with ultra-low density (≥0.08 mg cm-3) and ultra-high stiffness. This method is said to not only prove control of multiscale hierarchical graphene structures with high complexity, but “can be applied to other polymers or nanoparticle colloidal dispersion systems.”

Another approach, through the Water-Based Digital Fabrication project, developed by the Mediated Matter Group at the Massachusetts Institute of Technology (MIT, Cambridge, Mass., U.S.) Media Lab, applied a robotically controlled, multi-chamber extrusion system to deposit biomaterials like chitosan, derived from the natural polymer chitin, to create complex structures with anisotropic properties, multifunctionality and the potential for structural self-assembly. Fabrication trials described include a 50-centimeter-long structure inspired by dragonfly wings (see “Solution-based digital composites fabrication”).

Designing for damage tolerance

As demand increases for composites solutions that better tolerate damage, including failure mechanisms initiated by compression, biomimicry becomes an increasingly important source of inspiration. Design motifs in nature — including fibrous, helical, gradient, layered, tubular, suture and overlapping — all share a similar mechanism for damage tolerance. They dissipate energy via shearing between brittle materials; they also provide crack diffusion, crack deflection, crack arrest, pull-out mechanisms, friction, crack twisting, plastic deformation and crack blunting.

According to Richard Trask, professor of Advanced Materials in the University of Bristol’s Department of Aerospace Engineering, compression is “a massive Achilles heel for composites.” Much of his work has focused on ways to absorb energy and increase damage tolerance. “What we’re trying to figure out is if there is a way of changing the matrix material and/or the fiber, that is more akin to what we see in nature,” he says.

In partnership with Imperial College London, the University of Bristol is spearheading this initiative through a £6.2 million program grant from the UK Engineering and Physical Sciences Research Council (EPSRC), a five-year project begun in 2019. NextCOMP is tackling the challenge of composites performance in compression through the study of biological systems, “both to address practical limitations of current materials, and as a demonstration of the value of quantitative hierarchical design” found in nature. Mechanical modeling, resin systems, fiber platforms, ply level and bundle systems, and in-situ mechanical studies are the various levels in which project partners will demonstrate, observe and present findings, spanning applications from marine and automotive, to aerospace and the health care sector.

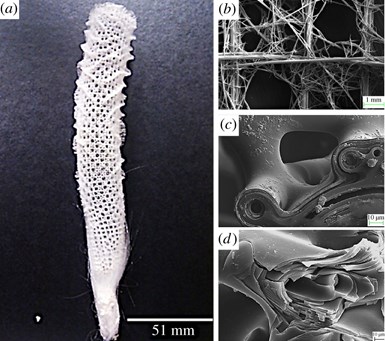

(a) Euplectella aspergillum cylindrical lattice skeleton (b, c) scanning electron microscopy (SEM) images of the organism's lattice-like interior and (d) an SEM image indicating the creation of crack-stopping and crack-deviating mechanisms. Photo Credit: "The structural efficiency of the sea sponge Euplectella aspergillum skeleton: bio-inspiration for 3D printed architectures," K Robson Brown, D Bacheva, RS Trask - Journal of the Royal Society Interface, 2019

Another project, supported by the UK EPSRC and sponsored by Airbus (Toulouse, France), studied a hexactinellid marine sponge, E. aspergillum, to inform the design of a lightweight fuselage that could be optimized against certain loads. Assessment of whether the sponge’s design features could be transferred to new architectures through AM was also considered. Previous work done by researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), in “Mechanically robust lattices inspired by deep-sea glass sponges,” characterized a sea sponge’s skeletal system as having diagonally reinforced square lattice-like structures in a checkerboard pattern. These lattices are able to withstand higher performance loads than traditional lattices without buckling, and offer a 20% increase in overall structural strength.

Trask and his team evaluated the skeletal lattice in an in-situ compression fixture using micro-computed tomography (μCT), characterized its hierarchical organization and generated a 3D representation for testing through finite element (FE) models to determine its replication capacity through 3D printing.

“The sea sponge is like a series of individual strands that are fused together. And that means you can allow the strands to deviate into different load paths. And when you try to subject it again to either a flexural bending load or a compression load, these points of contact [in the lattice] start to break. Each time they break, they eventually give you the flexibility to absorb more and more energy,” Trask says.

He notes that the strands, which vary in length and diameter, also contribute to damage absorption. “The sponge uses different lengths and diameters to control the regions which fail and hence can restrict the damage to select regions to allow the sponge to survive the attack and rebuild the lattice,” he adds.

According to Trask, while the specimens created “showed a similar initiation and propagation failure pattern to E. aspergillum, the macroscopic deformation behavior was altered to a more damage-tolerant, quasi-brittle failure mode. To my mind, there is still a need for further investigation to really bottom-out the reasons why.” Moreover, directly mimicking the material construction and design features were found to be beyond the current advances in AM. However, he acknowledges the considerable potential the results suggested.

Helicoid for improved damage tolerance

Like the overlapping design of nacre or lattices found in marine sponges, helical or coiled features are some of the most common structures found in biomaterials on a microscopic and macroscopic level. Organisms have evolved to use the helicoid to benefit from the significant performance improvements that this structure provides. These helicoidal structures are being explored and commercialized by Helicoid Industries (Indio, Calif., U.S.) through a family of patents and extensive knowledge and understanding of the technology.

In CW’s article, “Creating stronger composites through nature-inspired, Helicoid designs,” Dr. Lorenzo Mencattelli, director of R&D for Helicoid Industries explains that a helicoid’s constituent materials “are organized differently at each level to provide uniquely lightweight yet damage-tolerant structures.” Helicoid Industries, through its exploitation of raw materials, processes and applications — including carbon, glass and natural fiber-reinforced polymers (CFRP, GFRP, NFRP) — has demonstrated that its Helicoid technology is able to:

- Delay catastrophic failure by 74% (with thin-ply CFRP).

- Reduce localized dent depth by 50% (with aerospace-grade CFRP under low-velocity impact).

- Increase impact strength by >40% (measured for CFRP, GFRP and flax FRP).

- Improve residual compression strength after impact (CAI) by 20% and reduce notch sensitivity (OHT) with aerospace-grade CFRP.

- Improve impact fatigue of carbon fiber polypropylene composites by >40%

- Promote a more extensive use of natural fiber composites by demonstrating that bio-inspired hybrid Helicoid architectures made of 80% flax (by mass) and 20% glass achieve a similar perforation energy of conventional full (100%) glass fiber laminates.

The next steps are to work with producers in numerous industries with products for various applications to embed Helicoid structures to enable cost-effective manufacturability and scale-up.

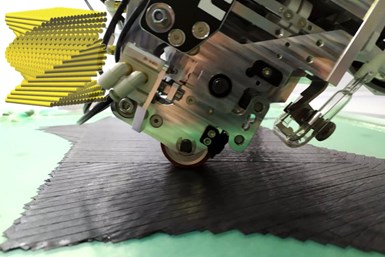

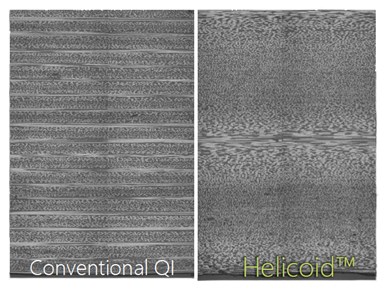

Using automated fiber placement (AFP), Helicoid Industries is able to tailor the rotation of each ply in a composite laminate, enabling improved structural integrity and better resistance to damage (top). This is illustrated in the micrograph (bottom), which depicts a conventional quasi-isotropic laminate versus Helicoid laminates. Photo Credit: Helicoid Industries

The commitment of Helicoid Industries to develop more sustainable composites is also underpinned by a recent SBIR awarded by the Department of Energy (DOE) in collaboration with Michigan State University (East Lansing) and its Vehicle Composite Center, targeting the use of biomimicry and Helicoid technology to enhance performance of natural fiber composite materials.

“We are very pleased to play an active role on the DOE’s pathway to decarbonizing America’s transportation,” Mencattelli says. “Natural fiber composite materials are already playing a crucial role for a more sustainable transportation industry. Through biomimicry, we can unlock the potential to deliver unsurpassed performance of these materials, opening new avenues for high-volume and high-performance green vehicle technologies. Our SBIR grant will accelerate Helicoid Industries’ ongoing development for a more sustainable transportation industry, to ultimately demonstrate the benefits of biomimetic composite innovation and technology in natural fiber composite products.”

Helicoid Industries CEO Chad Wasilenkoff notes several manufacturing processes that can make composites using the Helicoid technology, including automated fiber placement (AFP), hand or automated layup and filament winding — the latter of which the company has used to fabricate shafts, tubes and pressure vessels using glass, aramid and carbon fiber, all using various resins. 3D printing helical designs using continuous fiber-reinforced composites has also been explored on a lab scale level and is “a great match for additive manufacturing technologies,” but further evaluation is still ongoing and has yet to be commercialized.

For high-volume, high-rate manufacturing applications that require processing of dry fibers coupled with infusion processes, Helicoid is also collaborating with leading noncrimp fabric (NCF) suppliers to develop tailorable Helicoid multiaxial NCF preforms to partially embed Helicoid technology in a “single ply” to provide a cost-effective solution. Helicoid is also collaborating with a Tier 1 automotive part manufacturer in the U.S. that will use Helicoid multiaxial fabrics to create demonstrators for an EV underbody protective panel expected to be released in Q4 2022.

Regardless of whether it’s protection against rain erosion in the leading edge of wind blades, enhancing load-bearing structures for automotive (e.g., EV battery enclosures), improving the structural integrity and energy absorption in high-performance sporting goods and motorcycle helmets, or superior perforation resistance for composite blades for aircraft propellers and jet engines, “Helicoid composite laminates are able to outperform conventional solutions,” Mencattelli contends. “Highlights from numerous case studies show the wide range of applications that can benefit from Helicoid technology and are continuing to unlock its disruptive potential.”

The not-so-distant future

While the mechanical properties of biomimetic composites may not always exceed those of engineered synthetic materials, it’s clear that nature-inspired composites have a place in the future of this industry, even if more for inspiration than replication. In fact, emulation being the key goal of the biomimetic discipline, inspiration has been a common trend. “We have more synthetic materials to choose from than nature does ,” Trask emphasizes, “and we operate in a different kind of loading regime. And yet when we borrow structural ideas from nature, we suddenly expect them to behave the same way. I subscribe to the view that we are inspired by [nature], but can extend and can move forward with other ideas.”

“Biomimicry should never aim at copying forms, features or systems found in nature,” Mencattelli notes. “This is often a misconception that leads to using biomimicry in the wrong way. Rather, biomimicry should consist of understanding the relation between certain features/behaviors associated to structures/systems found in nature and their function. That is the greatest gift that we can get from observing nature. At that point, it is the engineer who has to understand how to apply that same structure-function relationship to enhance an engineering application.”

Part 2 of this article will delve deeper into composites manufacturing processes that have the potential to make bio-inspired structures a reality.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreRead Next

Bionic design: The future of lightweight structures

Biomimicry evolves into a systematic design process for optimizing efficient, lightweight structures.

Read MoreHyundai Motor, Supernal unveil eVTOL vehicle cabin concept

Concept details — such as CFRTP material incorporation, a biomimetic design and a focus on safety — provide a first look at how Hyundai integrate its mobility capabilities to develop commercial urban, regional air vehicles.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More