Additive Manufacturing

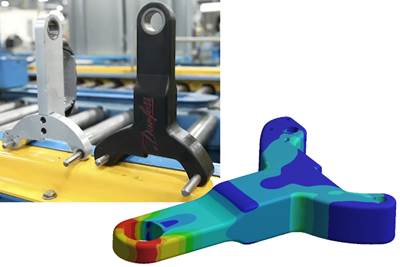

How to validate 3D-printed composite part performance

Integrated Computational Materials Engineering (ICME) workflow simulates composite material performance to speed development, optimize performance and reduce costs for a redesigned 3D-printed CFRP bracket.

Read MoreMakerBot 3D printing platform offers expanded advanced composite materials portfolio

Available through MakerBot Labs, the newly qualified 3D printing materials are ideal for demanding engineering applications that require high strength and heat resistance.

Read MoreRoboze raises funds for composites industrial 3D printing platforms

A diverse pool of domestic and international investors aid in the further acceleration of R&D for ultra-precise 3D printing of carbon fiber PEEK and other polymers.

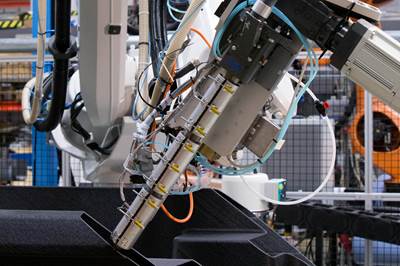

Read MoreAdaxis raises €1 million to combine 3D printing, industrial robotics

AdaOne software platform to be launched in 2022 supports automated, large-scale 3D printing with metals, plastics, composites and concrete to advance large-scale manufacturing.

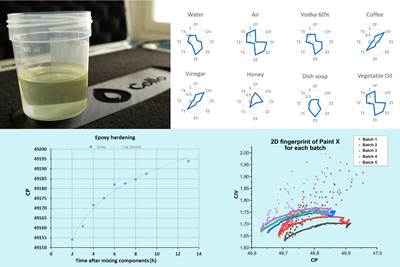

Read MoreFingerprinting liquids for composites

Collo uses electromagnetic sensors and edge analytics to optimize resin degassing, mixing, infusion, polymerization and cure as well as monitoring drift from benchmarked process parameters and enabling in-situ process control.

WatchCaracol obtains AS/EN 9100 certification for large-scale, robotic-mounted 3D printer

Italy-based large-scale AM specialist secures accreditation to produce aerospace parts. The company is currently scaling up production of various aircraft, launcher and satellite components.

Read MoreArris Composites announces Sustainable Consumer Products Program using Additive Molding technology

Oval bezel demonstrator for consumer electronics has sub-millimeter features, out-performs metal, is antenna transparent and more than 50% of the matrix comes from a renewable plant source.

WatchThermwood receives 32 granted additive manufacturing patents

New patents add to the company’s broad selection of already-patented LSAM equipment.

Read MoreAuburn University make strides in advancing bio-based polymers and fibers for 3D-printed home construction

Interdisciplinary project utilizes biomaterial waste for sustainable composites development to produce resilient buildings with a low carbon footprint.

Read MoreCollaboration agreement with Kanfit expands Massivit 3D into defense market

The Massivit 10000 printer will be installed at Kanfit’s facility and used by customer beta testers to produce large-scale molds, production tools for carbon fiber and fiberglass parts.

Read More