Roboze raises funds for composites industrial 3D printing platforms

A diverse pool of domestic and international investors aid in the further acceleration of R&D for ultra-precise 3D printing of carbon fiber PEEK and other polymers.

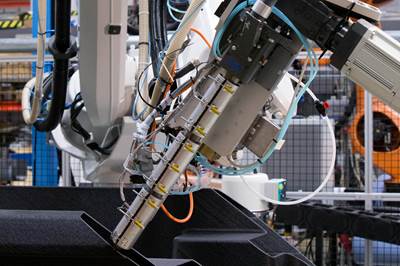

Photo Credit, all images: Roboze

Roboze (Houston, Texas, U.S.), known for its industrial 3D printing of high-performance polymers and composites for the aerospace, transportation, energy and medical industries, has announced successful company investment by a group of international investors, including Nova Capital (holding company of financial investments headed by Paolo Merloni, executive chairman of Ariston), Lagfin (Campari Group Holding), Andrea Guerra (former CEO of Luxottica, now CEO of LVMH Hospitality Excellence), Luigi De Vecchi (chairman EMEA at Citi), Roberto Ferraresi (CEO of The Equity Club), Luca Giacometti (CEO of Galileo SPAC), Denis Faccioli (CEO of Tecres SPA) and others.

The group joins the existing pool of investors, including Alfredo Altavilla (president of Ita Airways), Boris Collardi (former CEO of Julius Baer), Diego Piacentini (former senior VP of Amazon), Federico Faggin (inventor of the microprocessor) and Equiter SPA (investment fund held by Intesa San Paolo and Compagnia di San Paolo).

“This further fundraising will accelerate our momentum in the U.S. and will enhance our investments in research and development [R&D]. Specifically, the funding will assist in the creation of new super material in our Italian R&D center, where we are building a new chemistry laboratory,” says Alessio Lorusso, founder and CEO of Roboze. “We are honored to have a group of investors of this caliber, who strongly believe in the vision of Roboze and in the change of production paradigm that our technology is enabling by replacing metals and producing parts without wasting raw materials.”

Carbon fiber-reinforced PEEK CubeSat.

Founded in 2015, Roboze specializes in metal replacement 3D printing. Its patented, ultra-precise 3D printing technologies — Argo 1000, Argo 500 and Roboze One + 400 Xtreme — are equipped with a heated chamber, enabling the rapid production of end-use parts made from composites such as polyetheretherketone (PEEK) and carbon fiber-reinforced PEEK with high accuracy and repeatability.

Moreover, Roboze says its platforms create a circular and sustainable production model, reducing transport and related CO2 emissions, delivering parts just in time and on demand and avoiding unnecessary waste. Roboze currently works with GE Aviation (Cincinnati, Ohio, U.S.), Bosch (Gerlingen, Germany), Airbus (Toulouse, France) and other global organizations across aeronautics, space, energy/sustainable energy, medical, manufacturing and more to design and create end-use parts.

Roboze is currently working with industrial manufacturing giant, Siemens Energy (Munich, Germany), to create on-demand parts manufacturing and sustainable warehousing.

“We think additive manufacturing is playing a key role in digitalization and cost out in the energy sector. At Siemens Energy we evaluated many companies and found that Roboze technology for high-temperature polymers has met our engineering qualification and expectations. As a result, we acquired our first machine and look forward to expanding our relationship with Roboze,” says Andrew Bridges, service frame owner at Siemens Energy.

According to the company, 2021 was also year of momentous growth. The organization’s global team now exceeds 100 people, and the company is implementing an aggressive hiring plan in 2022 across the U.S., Italy and Germany with plans to hire 60 “super experts” within the next 12-18 months. Thirty of those hires will be in the U.S., specialized in materials science, chemistry, business development, aerospace, medical devices, field and applications engineering.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Adaxis raises €1 million to combine 3D printing, industrial robotics

AdaOne software platform to be launched in 2022 supports automated, large-scale 3D printing with metals, plastics, composites and concrete to advance large-scale manufacturing.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More