Additive Manufacturing

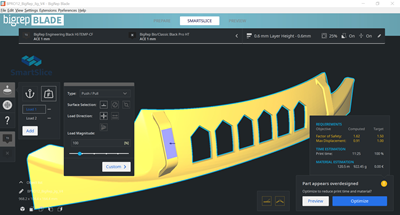

BigRep, Teton Simulation partnership integrates SmartSlice into large-format 3D printing

High-quality, production-level parts capability now available for large-format 3D printing, with current compatibility with BigRep PRO HT and HI-TEMP CF filament materials.

Read MoreSuprem launches continuous fiber-reinforced thermoplastic brand tailored to AM

Filaprem materials feature high quality, exceptional fiber/matrix distribution and low porosity.

Read MoreCreating stronger composites through nature-inspired, Helicoid designs

Helicoid Industries claims 50% increased toughness, impact strength and reduced material, weight and cost versus quasi-isotropic “fail-safe” designs.

Read More3D-printed continuous fiber dental reinforcements enter clinical trial

Hi-Fiber, partnering with Malo Clinic, is a dental reinforcement brand producing continuous glass fiber dental structures using Moi Composites’ CFM technology for a natural smile.

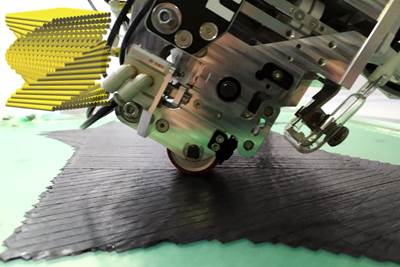

Read MoreNREL explores novel manufacturing approach for next-generation wind turbine blades

3D printing of thermoplastic blades enables thermal welding and improves recyclability, offering the potential to reduce turbine blade weight and cost by at least 10%, and production cycle time by 15%.

Read MoreScandinavian-inspired Japanese furniture brand debuts customized carbon fiber lounge chair

Mishima’s lounge chair frame is constructed via AM from a single piece of continuous carbon fiber, originally developed for the rigors of aerospace.

Read MoreScheurer Swiss commissions composite geo-alarm system to detect natural disasters

Carbon fiber-reinforced 3D printed inserts with glass fiber insulation are bonded to carbon tubes with fast-cure epoxy. The alarm system itself is mounted in areas like rock crevices to detect vibration and movement.

Read MorePurdue University composites center opens large-scale additive lab, seeks consortium partners

Purdue’s Composites Manufacturing and Simulation Center (CMSC) cut the ribbon on the Thermwood LSAM Research Lab, which partners can access with Purdue’s ADDITIVE3D simulation module.

Read MoreMVP releases new model of RAM system for thermoset materials

New large-format AM machine model, RAM 48, maximizes production efficiency and enables custom build dimensions when fabricating thermoset materials.

WatchAIM3D multi-material 3D printer targets precise, cost-effective polymer processing

Extrusion 3D printer offers considerably faster build rates and can print up to three different materials in parallel for metals, ceramics and high-temperature plastics such as PEEK and PPS with or without fiber filling.

Read More

.jpg;maxWidth=300;quality=90)