Adhesives

Tooling for composites: Evolutionary trajectory

New technologies and improved methods keep up as tools get bigger and more complex and toolmaking gets ever more challenging.

Read MoreTooling boards improve processes

In the composites industry, many parts are the product of one-off or few-of-a-kind production programs. In response, tooling material suppliers today provide an increasing variety of relatively inexpensive materials grouped under the heading of tooling board.

Read MoreSAMPE 2011 Long Beach Product Showcase

Huge show, huge new product offerings … huge success.

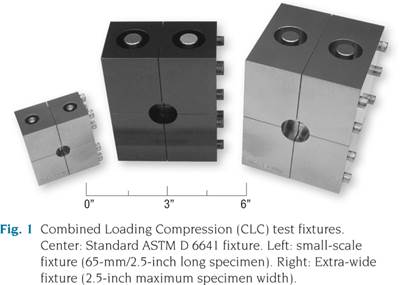

Read MoreThe Combined Loading Compression (CLC) test method

Dr. Don Adams discusses the relative merits of the ASTM-adopted combined loading compression (CLC) test method.

Read MoreHigh-speed press cure for high-speed racers

Trapped tooling and compression molding bring cocuring efficiencies to previously autoclave-cured, aerodynamic fins and planes.

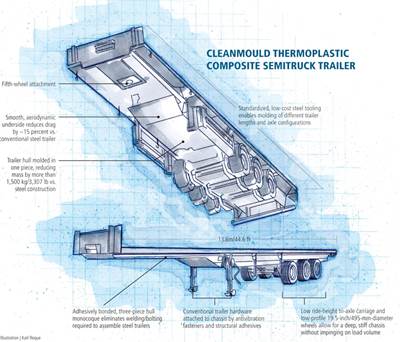

Read MoreThermoplastic composites: Sustainable transport

Cyclic PBT oligomers used to mold Class 8 semitrailer bed via vacuum-bag processing.

Read More3-D preforms: Fast, efficient blade-root manufacture

To expedite the blade root manufacturing process for wind turbine blade manufacturers, 3TEX Inc. (Cary, N.C.) has developed RapidRoot, a 3-D preform.

Read MoreWind blade manufacture: Opportunities and limits

At CompositesWorld's 2011 Wind & Ocean Energy Seminar, held April 13-14 in Portland, Maine, Stephen Nolet, principal engineer/director of innovation at TPI Composites Inc. (Scottsdale, Ariz.) briefed the audience on TPI’s view of blade design and manufacture.

Read MoreSAMPE 2011 at a Glance

This article is a sidebar to the main story on SAMPE's 2011 Convention and Exhibition, which will be held in Long Beach, Calif., May 23-26. To read the main article, click on "SAMPE 2011 ....." under "Editor's Picks" at right.

Read MoreThermoplastic composites: Primary structure?

Yes, advanced forms are in development, but has the technology progressed enough to make the business case?

Read More