Adhesives

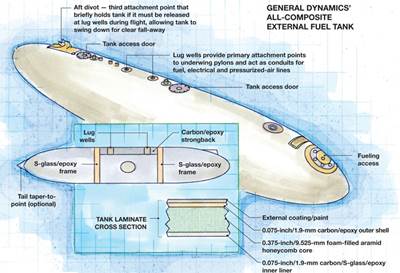

Carrier-capable, all-composite external fuel tank

Legacy product positions builder for a shot at an F-35 contract.

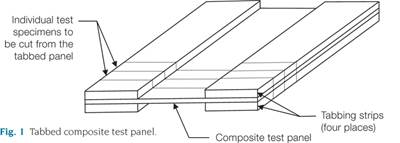

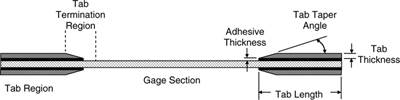

Read MoreTabbing composite test specimens: The how

The when and why of tabbing composite test specimens were the subjects of my previous column (see “Tabbng composite test specimens: When and why," under "Editor's Picks," at right), which included a discussion of tabbing materials, tab thickness and taper angle, and adhesive selection.

Read MoreJEC Paris 2011 highlights

The news from this annual Parisian in-gathering of composites professionals is heavily weighted toward automotive lightweighting.

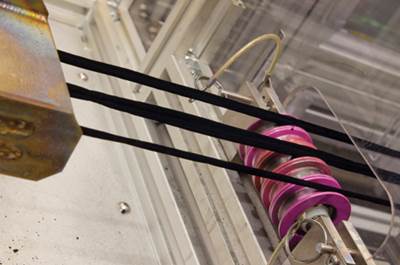

Read MoreNanotechnology: Into the realm of real

Fast, scalable process grows nanostructures directly on composite reinforcements for a “drop-in” use in volume production processes.

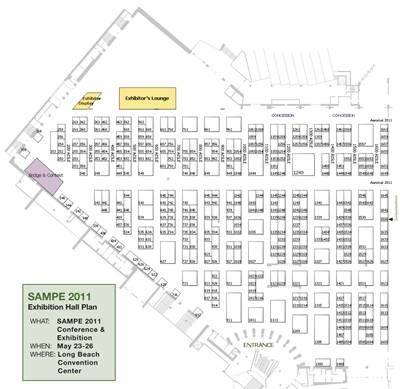

Read MoreSAMPE 2011 Long Beach Exhibitor List

This SAMPE 2011 Exhibitor List is accompanied by a feature-article preview and a brief description of SAMPE show-related events, listed at top right under "Editor's Picks."

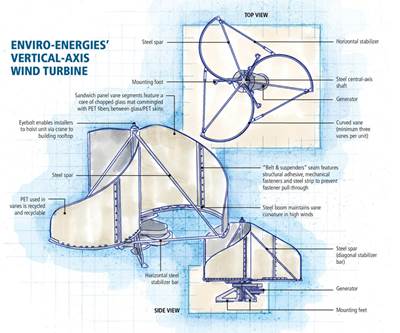

Read MoreSmall wind: Green energy gets greener

Kilowatt-rated vertical axis wind turbines supply green electric power where utility-scale turbines can’t.

Read MoreBlade repair: Closing the maintenance gap

Citing difficult work conditions, lack of OEM guidance and underdeveloped inspection technologies, those who service wind turbine blades seek remedial solutions.

Read MoreUnder the hood: Thermoplastics tackle tough jobs

Reinforced plastics save weight and cost, increase underhood productivity.

Read MoreTabbing composite test specimens: When and why

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses when and why test specimens must be protected by tabs.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read More