Aerospace

Thermoformable Composite Panels, Part II

Preconsolidated sheet stock for load-bearing applications features continuous fiber - not only glass, but carbon and aramid as well.

Read MoreNondestructive Testing Broadens Its Scope

Automation and integration of advanced NDT methods lead to faster, more accurate flaw and damage detection.

Read MoreLaser Imaging Material Speeds Aircraft Parts Into Production

A simple product is having a significant impact on composites fabrication at the Boeing Phantom Works' Accelerated Digital Design and Manufacturing (ADDM) group in St. Louis. RegiStar, a trademarked laser-imageable tape from Rohm and Haas Electronic Materials (Marlborough, Mass.), was developed as a marking system for

Read MoreSky's The Limit For Composites-intensive UAVs

Market growth is being spurred primarily by post-9/11 combat actions, homeland security and natural disasters.

Read MoreMcDonnell Douglas composite cryotanks — a personal history

Composites industry veteran Bob Hartunian looks back on a bold effort in 1987 to develop a thermoplastic composite cryotank for hydrogen storage. It gets complicated.

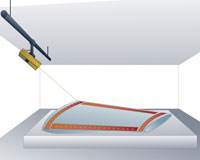

Read MoreRapid Fiber Preforming On A Large Scale

A proven alternative to open molding of big parts.

Read MoreRobot streamlines finishing of composite antenna covers

Sparks Fiberglass' (Rock Island, Ill.) first order for 50 8-ft/15.2m long fiberglass antenna covers for cellular telephone towers in 1998 kicked off a growth period for the company, in which manufacturing space quickly became scarce. When the company moved to a larger facility, it began looking for alternatives to the

Read MoreTesting cross-ply vs. unidirectional composites

Dr. Don Adams follows up his previous column on tensile testing with a discussion of such testing when confronted by two difficult-to-test laminate configurations.

Read More