Thermoformable Composite Panels, Part II

Preconsolidated sheet stock for load-bearing applications features continuous fiber - not only glass, but carbon and aramid as well.

In the world of reinforced thermoplastics, thermoformable composite panels for load-bearing applications are a relatively recent but fast-growing development. In structural and semi-structural composites applications, they were preceded by thermoplastic prepregs, which were developed to replace thermoset prepregs in niche aerospace applications. The resulting unidirectional tapes and semipregs featured continuous glass, aramid or carbon fiber reinforcements combined, early on, with engineering thermoplastics, such as polyethersulphone (PES) and polyetherimide (PEI) matrices and, more recently, with higher performing polyphenylene sulphide (PPS) and polyetherketoneketone (PEKK). But the expense of hand layup and the capital cost of machinery for automated manufacture (such as filament winding or automated tape laying equipment) have deterred growth. Thermoformable panels are helping suppliers overcome these barriers to product development and spur growth rates in the use of fiber-reinforced thermoplastics at a rate of 20 percent per year.

Unlike preconsolidated panels profiled in Part I (see CT April 2006, p. 36), structural-grade panels more closely resemble load-bearing thermoset advanced composites by employing continuous fiber reinforcement. Yet they represent a significant step forward compared to previous thermoset and thermoplastic technologies in that they shift responsibility for the fiber/resin ratio and fiber orientation or architecture to the panel manufacturer, freeing the part fabricator to focus on a smaller set of forming variables. This not only simplifies the fabricator's job but - because the panels can be mass-produced on automated production lines - increases the consistency and repeatability of finished reinforced thermoplastic components as well. Moreover, the fabricator's cycles are shorter, and finished products have greater toughness and impact resistance than thermoset composites and offer recyclability as well.

In the late 1980s, continuous fiber-reinforced thermoplastic sheet material was first used to form aircraft flooring for several European aircraft. More recently, structural parts made from thermoformed glass-reinforced PPS panels have been put to notable use on the wing leading edges of both the A340 and new A380 commercial airliners built by Toulouse, France-based Airbus Industrie (see "Thermoplastic Composites Gain Leading Edge on the A380," in CT's sister magazine, High-Performance Composites, March 2006, p. 50). These successes helped stimulate production of a number of similar products.

Structural Glass

Predominantly supplied as a unidirectional prepreg, Plytron, a polypropylene (PP) composite manufactured by Gurit (Flurlingen, Switzerland), also is sold in sheets formed from multiple layers of continuous glass/PP, with custom-tailored layup and fiber orientation. Currently, Glasseiden GmbH (Oschatz, Germany) supplies the fiberglass and Borealis A/S (Linz, Austria) provides the PP polymer. Both fibers and matrix were specifically developed for Plytron. Gurit is continuing Plytron optimization and development, with the help of these and other suppliers.

Typical layups are either 0°/90° or quasi-isotropic, but numerous stacking sequences are possible. Plytron sheets are consolidated and have a fiber content of 60 percent by weight.

Gurit markets Plytron as an alternative to commingled yarn products that combine glass and polypropylene fibers. Christophe Bourban, key account manager for Gurit Suprem, explains that Plytron preconsolidated sheet offers shorter cycle times than composites molded conventionally from raw fiber and resin - cycle times from 2 minutes to as little as 45 seconds can be achieved when stock is preheated between hot platens and then formed on a room-temp mold. Generally, thermoforming equipment heats parts to 185°C/365°F and applies 40 bar/4 Mpa pressure.

The one limitation may be with regard to part geometry. "If the part contains a deep draw or sharp curvatures, then slits in the material may be needed locally to ensure proper drapability," says Bourban. "However, parts have been produced with surprisingly good drapability at the cost of slightly longer cycle times."

Springs for high-quality Swiss bed manufacturer Bico are made using Plytron unidirectional plates, which are thermoformed and stamped. More than 5 million parts have been produced to date, with benefits including light weight, a virtually endless service life, and a competitive price. Plytron also has demonstrated its ability to offer Class A surface finish without additional and expensive surface treatment in automotive applications. BI Composites (Bridgtown, Cannock, U.K.) and MG Rover (U.K.) developed an automotive car hood, using a sandwich construction of PP nonwoven mat core and Plytron skins. "Advantages are the modest tooling costs, which allow for competitive pricing for small series of sport-version cars," says Bourban, adding that, in tests, "the use of PP near the heat radiated by the engine proved to be no problem, even for long-term service. This is possible due to the continuous glass fiber reinforcement. Unfortunately, MG Rover went bankrupt in 2005, so the bonnet did not become a commercial product."

To meet growing demand, Plytron production has been increased by a factor of five from 2004 to 2005 and further increases are planned for this year. The product is targeted for automotive components, such as floor panels, bumper beams and hoods, home appliances and pipe reinforcement as well as as local reinforcement in combination with GMT/LFT for high-volume applications. The product is currently available at a maximum width of 600 mm with an individual ply thickness of 0.27 mm. The sheet product can be supplied from 1,000 mm lengths to 440-meter rolls packaged on palettes. Future developments will include carbon fiber reinforcement and wider range of thermoplastics including polyamide nylon 6 (PA6), thermoplastic polyurethane (TPU), polyphenylene sulfide (PPS) and blends.

TWINTEX P PP is a consolidated plate made from TWINTEX commingled polypropylene (PP) and continuous glass fibers. TWINTEX commingled fiber was introduced in 1997 and is made by Saint-Gobain Vetrotex (Chambéry, France). The glass content is 60 percent by weight, and fiber reinforcement is either a balanced twill or plain-weave (4/1) fabric. Products include areal weights of 745, 935, 1,485, 1,870 and 2,970 g/m2. The recyclable material reportedly has excellent mechanical properties and its PP matrix lends it greater ductility and better dimensional stability in a wet environment than standard thermosets and other thermoplastics.

TWINTEX P PP is sold in standard widths of 104 cm or 152 cm (40.9 inches or 59.8 inches) and comes in rolls or cut-to-size plates. After preheating above the melt point of PP (180°C to 230°C/360°F to 450°F), TWINTEX thermoforms at various pressures, depending upon the exact forming process used: diaphragm - 1 bar to 8 bar (15 psi to 116 psi); thermo compression - 25 bar to 200 bar (363 psi to 2900 psi); sandwich thermo compression -1 bar to 5 bar (15 psi to 73 psi); or comolding with GMT or LFT as local reinforcement - 25 bar to 200 bar. TWINTEX also is now available with a thermoplastic polyester (PET) matrix.

TWINTEX reportedly has shown promise for thermoformable sandwich structures, featuring TWINTEX skins and either foam or PP honeycomb core. Produced as flat cored panels, they can be formed into shaped parts by low-pressure stamping. Textile coverings or carpets can be easily comolded during stamping for automotive interiors. Applications include the 4.2 kg/9.3 lb trunk floor developed by automotive systems manufacturer Peguform (Saint Marcel, France) for the Nissan (U.K.) Primera Estate. TWINTEX 935 g/m2 skins and polypropylene honeycomb core yield the specified stiffness-to-weight ratio. Peguform produces 100 parts per day using its patented Sandwiform molding process, in which carpet is comolded with the composite in a single step. Additionally, Jacob Composites (Wilhemsdorf, Germany) developed and manufactured 1,500 seat back structures for the BMW M3 CSL, using a sandwich of TWINTEX skins and polyether sulfone (PES) foam, with polyester carpet over-molded on one side in a one-step thermoforming process. The 5 kg/11 lb part offered more than a 50 percent weight reduction versus steel, as well as good acoustic insulation, excellent crash performance and low capital investment, due to the low-pressure molding process.

Plytron and TWINTEX also are marketed, in part, as effective local reinforcements for GMT and LFT compounds. For example, TWINTEX, a non-flowing material, can be selectively placed in specific local areas, in combination with either GMT or LFT, which are flowable materials, enabling the two systems to work together. The end-result is a part with integrated ribs, which have the necessary high section modulus, all in one-step molding.

Advanced Composites

Developed initially for aerospace applications, the following two products were developed as a more cost-effective alternative to the labor-intensive hand layup of thermoset prepregs. "A limiting factor of thermoset composites is the costly and complex autoclave process," explains Willem van Dreumel, director of research and development at Ten Cate (Nijverdal, The Netherlands). "Many smaller components like ribs, brackets and curved panels, are very suitable for thermoforming technologies, which offer a typical four-minute cycle time at a very low cost compared to autoclaved products."

Ten Cate developed the basic technology for Cetex continuous fiber-reinforced thermoplastic laminates in the 1980s, in cooperation with Delft University (Delft, The Netherlands). Standard Cetex products feature PEI or PPS matrices with glass, carbon or aramid fabric reinforcement. Glass is supplied by PPG Industries (Pittsburgh, Pa.) in the U.S., while the carbon fiber is sourced from Toray-Soficar (Abidos, France). PEI is supplied in granulate form by GE Plastics (Pittsfield, Mass.) and PPS is supplied as film by Amcor (Ghent, Belgium) and as granulate by Ticona (Kelsterbach, Germany). Sheets are typically 3.8m by 1.3m (12.5 ft by 4.3 ft) and range in thickness from 0.2 mm to 50.0 mm.

Thermoforming guidelines for carbon fiber/PPS Cetex sheets recommend preheating at temperatures between 300°C and 330°C (572°F and 626°F), with tool temperatures of approximately 180°C/356°F, at a forming pressure of 40 bar/580 psi.

According to van Dreumel, there are roughly 1,500 different part numbers in Cetex PEI or PPS composite on Airbus aircraft. This number is expected to grow significantly with many thermoplastic composite parts on the new Boeing 787 and the development of the Airbus A350.

Ten Cate also supplies the material for the A380 engine air intakes made by Airbus France. "The air intake is an innovative no-splice design made possible by the use of thermoplastics. The acoustic liner is manufactured as a single barrel, vesus the traditional two to three panels, which removes the acoustic disturbance caused by the spliced joints, giving the A380 a very low noise profile," says van Dreumel.

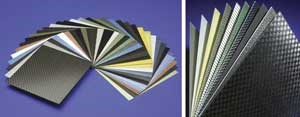

TEPEX dynalite, developed by Bond-Laminates (Brilon, Germany), is available as semi-preg or preconsolidated sheet. The sheet stock is available in a wide variety of combinations of glass, carbon and/or aramid fibers and PP, TPU, PPS, and polyamide (PA 6/Nylon 6), PA 12, PA 4,6 and PA 6,6 matrices. Sheets are consolidated in a double-belt laminating press, resulting in products with less than 2 percent void content and fiber volumes ranging anywhere between 35 and 55 percent, in thicknesses as thin as 50 mm to as thick as 6.0 mm, and may include up to 20 layers. "The dynalite materials offer customized layup, varying reinforcement type, thickness and fiber volume to satisfy the cost and performance requirements of a specific application," says Bond-Laminates' managing director Joost van Lindert. "It is our philosophy to solve many application development issues by optimizing the material rather than leaving the developers to maneuver around engineering compromises with the standard materials."

Bond-Laminates also produces a TEPEX flowcore product, which consists of long fibers (30 mm to 50 mm or 1.18 inches to 1.97 inches), similar to traditional GMT materials, with the difference that they are based on engineering resins. For example, TEPEX flowcore 102-RGR/PA6 is a commercial-grade product with random glass reinforcement (RGR) and PA 6 matrix.

"These materials are often combined with dynalite to enable the molding of stiffeners and ribs along a continuous fiber-reinforced structure," says van Lindert. The TEPEX dynalite material (fabric-reinforced) and the TEPEX flowcore material (random-fiber reinforced) both come in sheet form, are heated and placed in the mold together. The material size is slightly smaller than the final part size. The flowcore material flows to the edges of mold cavities and fills the rib and stiffener shapes in the mold. "It is very cost-effective, as it eliminates the cutting procedure after molding a part, which also reduces the cutting waste to virtually zero." TEPEX flowcore materials are intended for automotive and industrial structures for which technical requirements cannot be met by glass/PP, GMT or injection molded thermoplastics.

"Most TEPEX materials have cycle times of 30 to 60 seconds, depending on the level of automation the customer has installed," says van Lindert. "The main variable is the cooling time of the thermoplastic matrix in the tooling." TEPEX dynalite fiberglass-reinforced and carbon fiber-reinforced polyamide 6,6 composite laminates require forming temperatures between 280°C and 300°C (536°F and 572°F), and consolidation pressures of 5 to 100 bar (73 psi to 1,450 psi). He notes that molding temperatures for PP- and TPU-based products range from 190°C to 300°C (374°F to 572°F). TEPEX can be supplied in a maximum width of 1,350 mm/53.2 inches in lengths limited only by transportation requirements, or in customer-specified sheet sizes.

The dynalite glass/PP and glass/PA6 are used mainly in automotive applications replacing aluminum for cost and weight savings. Glass/TPU and carbon fiber/TPU are primarily used in orthopedic and sporting goods applications, offering superior performance, compared to unreinforced plastics. Carbon fiber/PA 66 dynalite was developed for structural sporting goods and helmet shell applications, and PPS materials are being used in aircraft interiors at lower cost than traditional thermoset composites. Dutch Thermoplastic Composites (Lelystad, The Netherlands) is thermoforming 0.2-mm to 5.0-mm-thick (0.01-inch to 0.20-inch) sheets of Tepex carbon fiber/PPS to replace aluminum in lumbar and thigh supports, armrest table covers and shields for video screens. The Tepex lumbar support weighs around 150g/5.3 oz, saving 130g/4.6 oz versus the aluminum part at 280g (9.9 oz). This cuts roughly 72 kg/158 lb per aircraft in a 555-seat configuration on the Airbus A380. Other applications include an advanced composite sandwich material applied in the new generation of Bowers & Wilkins loudspeakers and a high performance ski boot developed by Rossignol-Lange, using overmolded TEPEX dynalite/TPU (see photo p. 32).

New to the market is Porcher Industries' (Badiniéres, France) line of preconsolidated thermoformable and weldable sheet stock. The sheet stock is made from its PiPreg reinforced thermoplastic prepreg material, available in either unidirecitonal or woven E- and S2-glass, carbon, or aramid fibers impregnated with any one of a number of high-performance thermoplastic resins, including PEEK, PPS, PEI, TPU and polyamide 12. Reinforcement, resin, fiber orientation and fiber/resin ratio can be tailored to the end use. Benefits include increased composite parts manufacturing speed and the possibility of making prototypes and pre-series in low quantities.

Cored & Core-like Panels

Using a single-step manufacturing technology, FITS Technology (Driebergen, The Netherlands) produces lightweight, high-strength, high-stiffness FITS (Foamed In-situ Thermoformable Sandwich) panels, featuring an isotropic PEI foam core bonded to continuous fiber-reinforced PEI faceskins. FITS was initially developed in a Delft University research program. "The goal was to make a product having an airy core with solid surfaces, similar to the excellent structural design of bones," notes FITS managing director Martin de Groot.

One of the initial targets for FITS is replacement of traditional aramid honeycomb cored sandwich panels in overhead storage bins on commerical aircraft. Roughly 25 percent of aramid-cored panel weight comes from potting compound, paint, inserts, and decorative surface film. For FITS panels, this drops to only 5 percent. "FITS cannot compete with aramid on its own because the honeycomb core is so lightweight," says de Groot. "However, FITS can compete if you take advantage of its its potential to eliminate ... potting of fastener holes and waiting for potting compound to cure before installing fasteners." In FITS panels, thermoplastic fastener inserts can be installed via ultrasonic welding, offering dramatic time and cost savings. "So with FITS, you start with a higher weight panel, but end up with a lower weight finished part at a much lower cost for high-volume applications," de Groot maintains.

FITS panel thus meets all end-use part requirements and offers a 5 to 50 percent weight savings at a very significant reduction in final part cost, says the company. If the weight and cost reduction demonstrated for overhead storage compartments were extended to other interior components - cargo ceilings and floors, cabin floors and components for galleys and trolley carts - the total savings per aircraft could be significant, says de Groot. Reportedly, FITS panels meet all flammability and smoke toxicity requirements for aircraft interiors and have greater damage tolerance and peel strength than honeycomb-cored sandwich panels.

Typical thermoforming temperatures for FITS are 330°C to 350°C (626°F to 662°F), which is a little lower than the glass transition temperature of the PEI facings. Forming pressure is around 0.321 Mpa/47 psi, depending on the density of the in-situ PEI foam. A heated die or tool is used for shaping followed by a consolidation die or tool, which is kept at a temperature below the melt temperature of the thermoplastic faceskins. The process can include in-mold decoration: Faceskins can be colored white or receive a transferred decoration - using a printed paper technique.

A wide variety of faceskins are available in addition to PEI, including PES and polyphenylene sulfone (PPSU). Facings are reinforced with style 7781 fiberglass fabric impregnated to a fiber content of 32 percent by volume, but may also use aramid and carbon fibers. Top and bottom faceskins are typically 0.7 mm/0.7 inch thick and faceskin layups per panel can be 1 ply top/1 ply bottom, 1 ply top/2 plies bottom and 2/2. FITS panels are manufactured with a thickness of 5 mm to 25 mm (0.2 inch to 1 inch) and a density of 85 kg/m3 to 150 kg/m3 (5.3 lb/ft3 to 9.4 lb/ft3).

Rail-Lite thermoformable long glass fiber-reinforced thermoplastic (LFRT) sheet is supplied by Azdel Inc. (Southfield, Mich.), a joint venture of GE Advanced Materials (Pittsfield, Mass.) and PPG Industries. Rail-Lite is made from GE's Ultem PEI resin. During processing, the glass-reinforced PEI resin expands, lending the matrix a foam-like character that provides desirable sound absorption and heat-insulation properties. Additionally, about half its volume is air, making the material very lightweight - about half the specific gravity of aluminum and fiberglass panels of similar or equivalent strngth and stiffness. Additionally, PEI is inherently fire retardant, enabling it to char when exposed to flame, emitting very low levels of smoke.

Rail-Lite forms the structural component of HushLiner FR acoustic panels produced by Azdel partner and acoustic/thermal insulation specialist American Acoustical Products (Holliston, Mass.). The proprietary five-layer sandwich panels are designed for use as contoured acoustic ceiling panels. The panel's top layer is a perforated solvent-, stain- and graffiti-resistant Indura GT decorative laminate film, developed by Schneller Inc. (Kent, Ohio) for contoured railcar interior surfaces. Metro-North Railroad, the third-largest commuter railroad in North America, is using HushLiner FR as a replacement for traditional acoustic ceiling panels in its passenger railcars. The panels comply with the ASTM flame and smoke standards mandated by the U.S. Federal Railroad Assn. (U.S. FRA 49 Code of Federal Regulations [CFR] Part 238) for train passenger cars and locomotive cabs, as well as Germany's DIN5510, Part 2 S4/SR2/ST2 rating. Azdel is marketing Rail-Lite into rail interior components such as window masks, ceiling panels, seat backs, arm rests, tray tables, stowage bins, valances, and partitions. GE Advanced Materials also has formed a joint development agreement with the largest OEM supplier of train interiors in China, which plans to use multiple grades of Rail-Lite in its passenger train interiors.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More