Aerospace

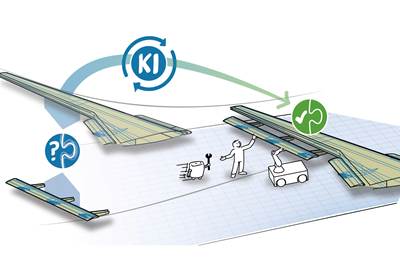

DLR develops concept for final assembly line with artificial intelligence

High-rate production enabled by pre-selection of assembly-ready components, without manual compensation measures, based on neural network training.

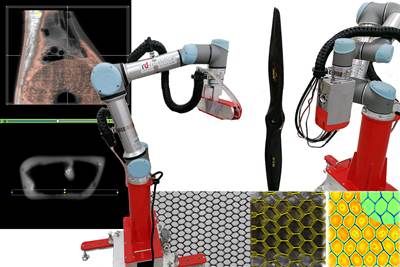

Read MoreRobotic computed tomography – removing NDT barriers for composites

Radalytica uses collaborative robots, ultra-sensitive X-ray photon detectors and the ability to combine CT with ultrasound, surface profiling and other inspection methods to optimize composites part quality, production and reduce cost.

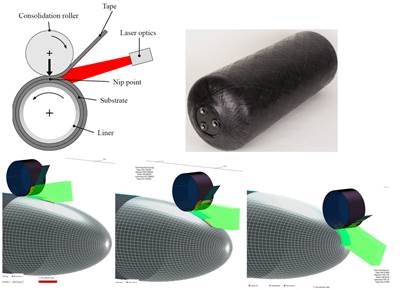

WatchOTOMcomposite develops software for Composites 4.0 production using laser-assisted tape placement and winding

Optical thermal optimization model (OTOM) software enables inline monitoring and control for improved part quality and reduced production time and cost of in-situ consolidated thermoplastic composites and Type IV pressure vessels.

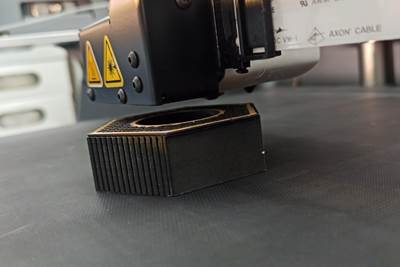

WatchMarkforged launches aerospace-ready traceable composite materials

Onyx FR-A and Carbon Fiber FR-A materials meet FST requirements, come with traceability and adhere to specifications approved by the National Center for Advanced Materials Performance (NCAMP).

Read MoreCobra supports new production concept for composites-intensive VETAL tailsitter drone

Cost-effective composite tooling and a scaled-up production line target durability, production rate and price parameters for the VETAL’s carbon fiber flying wing airframe.

Read MoreComposites in aircraft fuselage — now and in the future

What do some of the challenges of composites use on the 787 teach us about composites use on next-generation aircraft?

Read MoreSkye Aviation orders 15 Bye Aerospace eFlyer 800s

Aircraft leasing company to purchase from the company that developed the composites-intensive eFlyer 2 for an all-electric aircraft fleet.

Read MoreCAMX 2021 exhibit preview: Helicoid

Designed for toughness and impact resistance, Helicoid Industries’ biomimetic fiber distribution technology, Helicoid, enhances performance of composite parts.

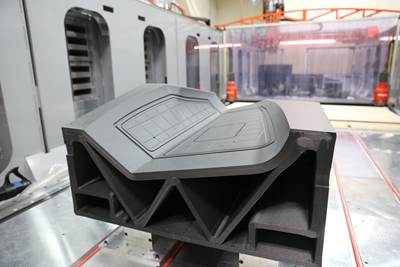

Read MoreCAMX 2021 preview: Ascent Aerospace

Tooling specialist Ascent Aerospace is emphasizing recently installed capacity to produce tools, molds and fixtures via large-format additive manufacturing at its Santa Ana, Calif., U.S., location.

Read MoreMaCoIMA project to develop the potential of composites additive manufacturing

The MaCoIMA (Innovative Composite Materials from Additive Manufacturing) project aims to develop new composite and hybrid materials for use in high-performance sectors such as advanced mechanics and aeronautics.

Read More