DLR develops concept for final assembly line with artificial intelligence

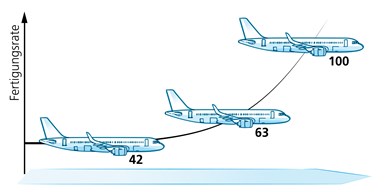

High-rate production enabled by pre-selection of assembly-ready components, without manual compensation measures, based on neural network training.

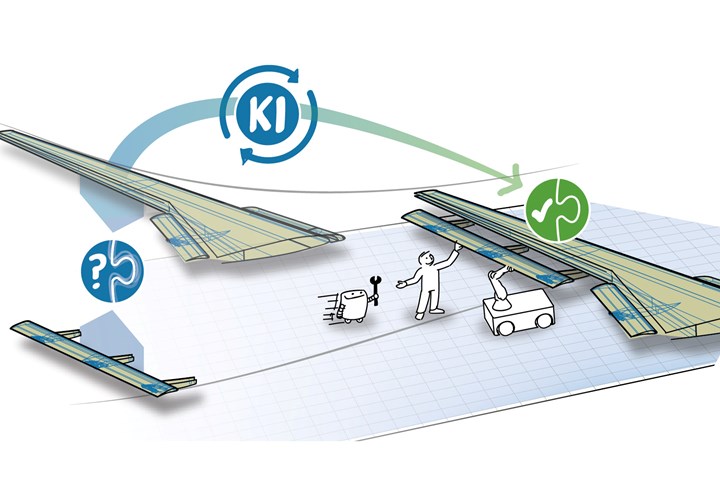

A final assembly line with artificial intelligence (künstliche intelligenz, or KI) can be implemented, with assemblability guaranteed at all times. Photo credit: article by Dr. Ing. Lennart Weiss, Institute for Composite Structures and Adaptive Systems.

In a 2021 article by Dr. Ing. Lennart Weiss, of the DLR Institute for Composite Structures and Adaptive Systems (Braunschweig, Germany), manual compensation procedures — for example, shimming —and the resulting delays are a thing of the past. Each assembly can be joined immediately using artificial intelligence, because a clever pre-selection of the components reduces excessively large tolerances at the connection areas. Even high-rate production is possible thanks to the “plug and fly” principle. DLR envisions the complete introduction of this expert system into series production.

Independent assembly decision

In an expert system, the artificial intelligence selects individual parts that can be assembled independently. The connection dimensions and their tolerances determine whether the components can be assembled. The neural network evaluates the recorded parameters, draws on its "experience" and signals a positive or negative assembly process. The neural network achieves empirical values through so-called monitored training cycles (supervised learning). This often requires a large number of independent assembly scenarios or data points. The greatest challenge is the limited availability of this training data for assembly processes in the final assembly line.

Computer-aided for small batch sizes

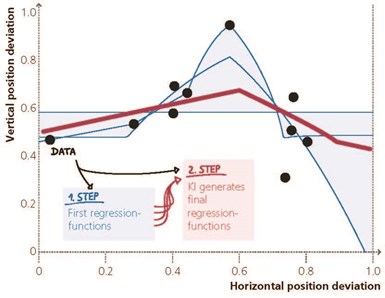

First and second step regression functions, where AI (shown here as KI for künstliche intelligenz) generates the final regression functions.

A two-stage process solves the problem in dealing with small lot sizes. Thefirst step of the process consists of training several neural networks. They represent various preselected approach functions. Their training for the best possible regression of the data points leads to the first "experiences". However, the influence of the preselection of shape functions on the regression result is too great. Therefore, in the second step, the algorithm is free to generate its own approach function based on its “experiences” from the first step and to carry out the training with this again.

The algorithm learns from its training experience and independently determines a regression function that is sufficiently predictive even for small batches. The artificial intelligence runs through this computer-aided process after each assembly, so that the wealth of experience grows with each positive or negative assembly process. This improves the prediction quality of the expert system with each assembly process carried out.

The learning expert system enables economical high-rate production based on the “plug & fly” principle. Complex compensation measures and downtime in the assembly line are a thing of the past. The expert system evaluates, in real-time, specific component information, such as tolerances at joints and provides presettings for guaranteed assembly as a recommendation for action to the assembler. Photo Credit: 2020 article by Dr. Ing. Lennart Weiss, DLR.

The learning expert system accompanies the final assembly line in series production. The knowledge gained can be used both for new flexible assembly concepts in the factory of the future and for a new construction philosophy for the designer of the future.

This article follows on from Weiss’ 2020 article, “Flexible Cooperation - with a learning expert system for intelligent assembly”.

Related Content

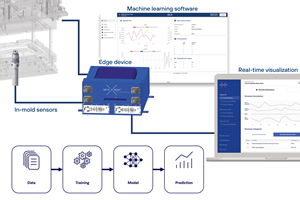

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MoreCom&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.

Read MoreAitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

Read MoreST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: A&P, Cincinnati, OH

A&P has made a name for itself as a braider, but the depth and breadth of its technical aptitude comes into sharp focus with a peek behind usually closed doors.

Read MoreModeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read More

.jpg;maxWidth=300;quality=90)