ATL/AFP

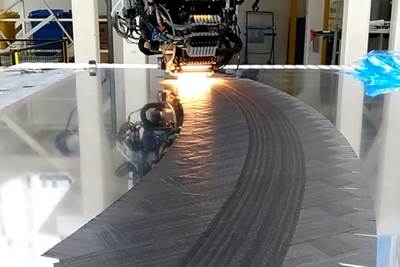

AFP tow steering comes of age, Part 1: Current state

It used to be enough that AFP systems could precisely and quickly place and cut multiple tows to build complex aerostructures. Now, fabricators need those tows steered, and the tighter the radius, the better.

WatchAVK announces winners of 2020 Innovation Awards

Several sustainable composite innovations were recognized and awarded in the Innovative Products/Applications, Innovative Processes and Research and Science categories.

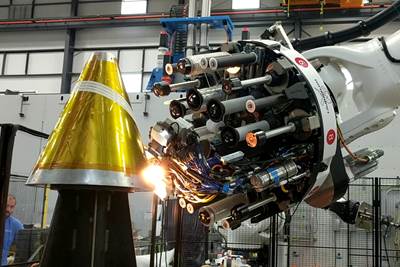

Read MoreFirefly Aerospace to automate composite rocket production with Ingersoll AFP machine

The company plans to transition manufacture of its Alpha and Beta all-composite launch vehicles to automated fiber placement starting in 2021.

Read MoreMoving forward on the Multifunctional Fuselage Demonstrator (MFFD)

Clean Sky 2’s MFFD program continues to move toward its goal of delivering a welded, thermoplastic composite fuselage demonstrator using next-generation manufacturing processes.

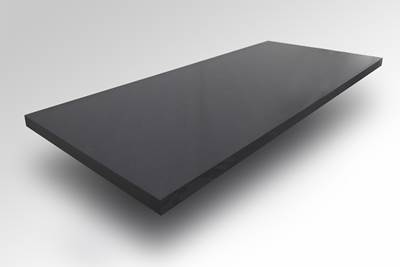

Read MoreVictrex, Daher, attain next-gen thermoplastic aircraft panel milestone

The developed panel is a 176-ply laminate, 32-millimeter-thick composite structure and uses Victrex AE 250 PAEK-based thermoplastic composites.

Read MoreLeveraging towpreg to reduce the cost of CMC

High-denier, spread-tow Nextel 610 fiber and novel alumina matrix enable AFP production of Ox-Ox ceramic matrix composites.

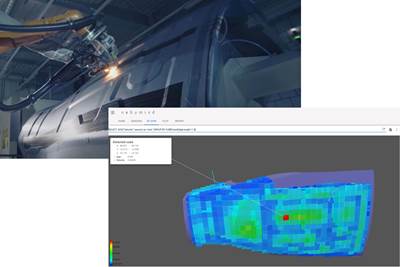

Read MoreUsing sensor data to improve composite parts and processes

nebumind software builds digital twins from manufacturing data to trace defects, compare manufactured parts, qualify processes, develop tolerance windows for process monitoring and more.

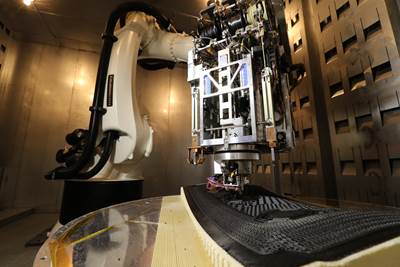

WatchCombining AFP with 3D printing for flexible parts production

Electroimpact creates a multifunctional manufacturing cell for complex, aero-quality continuous fiber composite parts.

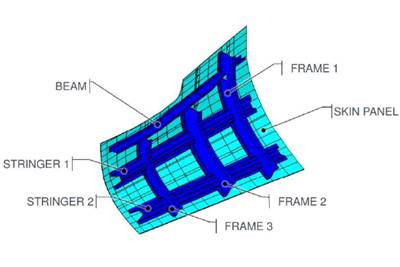

WatchFRAMES: Full-scale thermoplastic composite aircraft rear-end demonstrator

Clean Sky 2 project led by ESTIA-Compositadour will develop enabling technologies for optimum rear fuselage and empennage.

Read MoreAddcomposites and Effman partner to provide AFP cells for SMEs

Aim is affordable, enclosed composites manufacturing cells for many different processes (AFP, grinding, buffing, sanding, drilling) in North American market.

Watch

.jpg;maxWidth=300;quality=90)