ATL/AFP

Ultralight carbon fiber/epoxy road bike from Kestrel

Kestrel is the first name in carbon fiber bikes, on the strength of a lengthy list of bike-industry firsts that include the first-ever production carbon fiber bike frame (1986) and first all-carbon mountain bike frame in 1988. Recently, the company unveiled a new version of its Talon SL road bike. At $3,699, it isn't

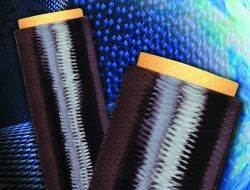

Read MoreAdvances in sizings and surface treatments for carbon fibers

As carbon reinforcements find new applications, unfamiliar processes and resin systems make sizing and treatment surprisingly hot topics.

Read MoreFiber Placement The Centerpiece Of NCAM

Cryogenic composites just one facet of Lockheed Martins National Center for Advanced Manufacturing.

Read MoreNew Equipment Brings Tape Placement Within Reach Of Smaller Shops

"Right-sized" automated tape laying head is simple and affordable.

Read MoreUkrainian Aerospace Developer Employs Clean Sheet Design

Antonov designs integral torsion boxes for highly loaded tail structures.

Read MoreTowpreg Proves Cost-competitive For Wound Pressure Vessels

Design group's new winding option streamlines new pressure vessel development.

Read MoreIsotruss offers amazing strength and material savings

The three-dimensional composite truss structure is the lightest and most efficient structural tube available.

Read MoreProven Performance In A Chemical Line Installation

EDO Specialty Plastics (Baton Rouge, La., U.S.A.) filament winds composite pipe and fittings for offshore facilities platforms and rigs. Founded in 1973 as Specialty Plastics and acquired by EDO in 1998, the company manufactures industrial fiberglass piping systems for the chemical, petrochemical and pulp and

Read MoreA Different, All-Composite Approach

Fiberglass Structural Engineering Inc. (FSE, Bellingham, Wash., U.S.A.) has patented its innovative concept for a hybrid fiberglass and steel platform. Approximately 50 percent of the volume of a conventional steel spar hull would be replaced by hollow filament-wound Eglass and vinyl ester tubes, from 10 ft to

Read MoreComposite Accumulator Bottles Perform In Service

A riser tensioning system for a TLP consists of a tensioning ring and framework, with four to eight hydraulic cylinders — each with an attached pressure vessel or “accumulator bottle” — to support and allow movement of the rigid riser pipe. Installed in the riser wellbay, this primary structural system is desi

Read More