Autoclave

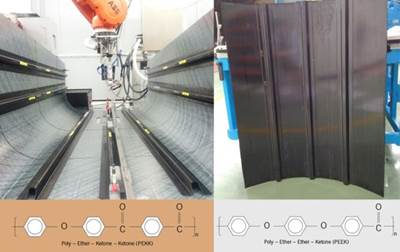

PEEK or PEKK in future TPC aerostructures?

Which is better for in-situ consolidated thermoplastic composite primary structures? Materials play a part as to whether a one-step or two-step process will prevail.

Read MoreThermoplastic composites: Past the tipping point?

The manufacturing world watched a decade ago as automatically placed thermoset composite tapes replaced aluminum in commercial airframes and made composites a household word in markets around the world. Has the time come for thermoplastic composite tapes to make a similar impact?

Read MoreSmarter molding with Smart Cauls

Spintech’s Smart Caul technology can be used to create internal mandrels, bladders for hollow parts or any irregular male layup tool shape involving a sharp angle or corner.

Read MoreVELOX, c-m-p develop hot-melt, solvent-free prepreg technology

VELOX GmbH has partnered c-m-p GmbH to develop a new hot-melt, solvent-free prepreg impregnation technology targeted toward automotive and sports equipment applications using autoclave or out-of-autoclave (OOA) processes, including compression molding.

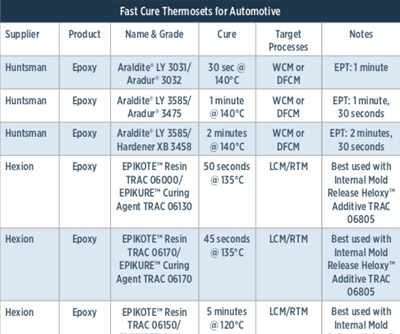

Read MoreFast and Faster: Rapid-cure resins drive down cycle times

New systems include sub-1-minute cures ideal for higher automotive production volumes.

Read MoreEmployment opportunity: Manufacturing Engineer

Qfix is seeking a Composites Manufacturing Engineer responsible for overseeing all manufacturing processes employed in composite production.

Read MoreMatrix Composites accredited by Nadcap

Matrix Composites, Inc. reports it will appear on the Qualified Manufacturers List (QML) for composites as a Nadcap accredited company.

Read MoreFive highlights from JEC World 2018

It’s not Spring without a trip to Paris, France for the JEC World 2018 composites conference. It’s become a very big show, and thus, offers some big announcements and some developing trends.

Read MoreQuickstep and ATR Group announce composites manufacturing partnership

Partners poised for strong presence in European market.

Read MoreJEC World 2018 preview: Solvay

Solvay (Hall 5, L42) is featuring composite materials and specialty polymers through several applications, including resin infusion for aerospace primary structures, Double Diaphragm Forming (DDF) rapid part manufacture, rapid-cure prepregs and Recyclate Molding Compound (RMC).

Read More