Automotive

Deadline reminder for the Lightweight Open Innovation Challenge

Innovators have until February 1st to submit their innovative lightweight solutions to two categories: materials and manufacturing.

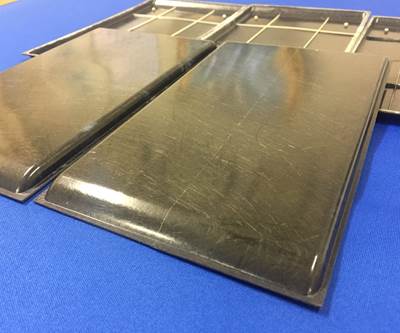

Read MoreFold-to-form CFRP battery boxes, HP-RTM wishbones

Williams new EV platform demos 223 composite forming process and £20 suspension arms using recycled carbon fiber.

WatchHybrid composite materials: tailoring for specific performance

I received a link to an interesting technical paper presented at CAMX by AGY (Aiken, SC, US). It got me thinking about hybrid composites.

Read MoreELG's new CARBISO product on display in Japan

ELG Carbon Fibre Ltd (Coseley, West Midlands, UK) will be exhibiting for the first time at the Automotive World Show in Tokyo from January 17-19, 2018. The company will introduce its trademarked CARBISO range of recycled carbon fiber products for high volume, automotive applications.

Read MoreA range of new products from Huntsman

Huntsman Advanced Materials used the 2017 CAMX show to showcase new products from its Advanced Materials and Huntsman Polyurethanes divisions, including advanced composite resin systems and adhesives.

Read MoreSulzer Mixpac introduces spray coating dispensing system

Sulzer Mixpac USA Inc., a provider of two-component adhesive dispensing systems, now offers the trademarked portable MIXPAC MixCoat Spray, a member of the MIXPAC MixCoat cartridge-based two-component dispensing system family.

Read MoreDriving down costs: Technologies to follow in 2018

Cost drives most decisions about composites use, but most innovation now focuses beyond material cost.

Read MoreCAMX 2017: Highlights from the floor

3D printing and nanotechnology developments promise to cut time and cost in composite structures production while recycling and sustainability continue to grow in importance.

Read MoreCarbon Fiber 2017 final highlights

Applications and enabling technologies for carbon fiber promise new market penetration – challenges notwithstanding.

Watch

.jpg;maxWidth=300;quality=90)