Braiding

Wind Blade Manufacturing, Part I: M and P innovations optimize production

As demand for wind turbines reaches unprecedented levels, rotor blade manufacturers explore new production strategies, including automation and blade segmentation.

Read MoreHigh-Volume Preforming for Automotive Application

More than a dozen parts for four Aston Martin models are mass produced in France using Ford Motor Co.'s optimized Programmable Preforming Process and resin transfer molding.

Read MoreComposites and Polymer Concrete Refine Mining Processes for Nonferrous Metal

Cost-effective alternatives to steel-reinforced concrete offer corrosion-resistant acid tanks to electrolytic refinery operations.

Read MoreStructural health monitoring: Composites get smart

New initiatives are mainstreaming real-time monitoring systems into composites on aircraft, wind blades and other critical performance structures.

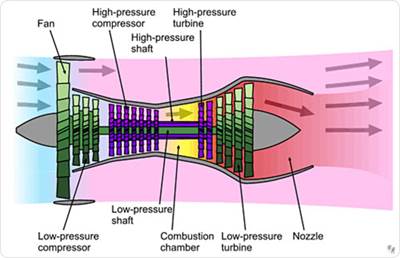

Read MoreAviation Outlook: Composites in commercial aircraft jet engines

Airlines' need for fuel-efficient flight provides the thrust behind composite lightweighting strategies in jet engine manufacturing.

Read MoreSAMPE ’08 technology showcase

Billed as the world’s largest advanced materials trade event, SAMPE’s 2008 Symposium and Exhibition returned to Long Beach.

Read MoreBuilding Bridges to Bridge and Building Rehab Markets

Despite a lack of standardization and education in the civil construction sector, these innovators use carbon and steel fibers to reinforce the business case for composites.

Read MoreMarket Trends: This industry is ready to explode

I recently was invited to speak at the COMPOSITESWORLD Carbon Fiber Conference, held Dec. 5–7, 2007, in Washington, D.C. As usual it was a successful gathering of fiber manufacturers and users. As a consultant to the composites industry, I’ve tracked carbon fiber supply and demand for years. Some of you might remember

Read MoreAligned discontinuous fibers come of age

Discontinuous but aligned carbon fibers are proving formable and formidable in high-performance, compound-curvature applications.

Read MoreTooling Update: New dimensions in tooling

Nanoenhancements, out-of-autoclave strategies and low-pressure RTM headline efforts to increase mold quality and productivity and cut tool cost.

Read More

.jpg;maxWidth=300;quality=90)