Ceramic Matrix Composites

AMULET project funds 24 projects in composites, CMCs, metals

Trans-European project finalists for first open call identify material and process innovations in building, aerospace and aeronautics, energy and automotive sectors.

Read MoreCVD Equipment received $3.7 million aerospace order for production coating system

The CVI system will be used to manufacture ceramic matrix composite (CMC) materials for aerospace gas turbine engines.

Read MoreHeat resistance testing provides insight into preventing carbon fiber-reinforced UHTC degradation

Japan-based researchers use an arc-wind tunnel to better understand carbon fiber-reinforced ultrahigh-temperature ceramic matrix composites oxidation resistance in high-temp, inert atmospheres.

Read MoreEU-funded webinar highlights high-performance material and component innovations

Online, international event taking place Nov. 15, 2022 is open to industry, presents six EU-awarded projects and their first results, among them CEM-WAVE for CMC.

Read MoreNCC successfully demonstrates AFP manufacture of CMC parts

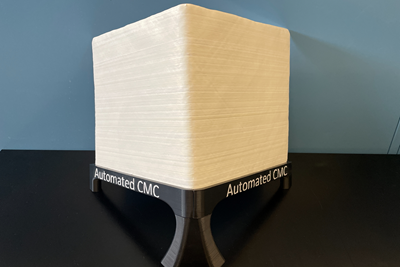

Core Research program adapts existing AFP technology and identifies optimal deposition parameters using a novel 3M towpreg material for wider CMC use.

Read MoreL&L Special Furnace commissions high-temp box furnace for CMC parts

Multi-layer, high-temperature insulation, enables temperatures up to 1,700°C under partial atmospheric pressure for CMC parts production to be used in military and aerospace applications.

Read MoreLockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Targeting current and future needs in hypersonic and aeronautics applications, Lockheed Martin Skunk Works’ Allcomp team is increasing and digitizing its capabilities in ceramic matrix composite (CMC) materials and parts fabrication.

Read MoreAxiom partners with NIAR ATLAS for oxide-oxide CMC research

Partnership breaks cost and process scalability barriers through the development of oxide-oxide CMC prepreg using AFP technology.

Read MoreRATH prepares for production of advanced oxide ceramic fiber for CMC

New facility in Germany is part of regional supply chain and vision to lead green energy transition using CMC, supported by German government and Composites United’s Ceramic Composites network.

Read MoreMulti-composite thrust chamber aims to boost rockets, reduce cost for New Space economy

Black Engine uses new, microporous CMC liner for transpiration cooling and multiple lightweight composites in modular design that offers increased lifetime and lower maintenance versus current launch vehicle engines.

Watch

.jpg;maxWidth=300;quality=90)