Ceramic Matrix Composites

GE Aviations opens CMC facility in Alabama

The $200 million facility will manufacture silicon carbide (SiC) materials used to manufacture ceramic matrix composites (CMCs), for GE and LEAP aircraft engines.

Read MoreEpisode 8: Ryan Huth, GE Aviation

Ryan Huth, manager of ceramic matrix composites (CMC) production at GE Aviation’s Asheville, NC facility, talks about CMC technology, GE Aviation's CMC parts production and the future of both.

ListenGE starts GE9X certification testing

As the second GE9X engine begins testing at the Peebles Test Operation (PTO) in Ohio, assembly of the third and fourth GE9X engines is well underway at GE Aviation’s headquarters in Evendale, Ohio.

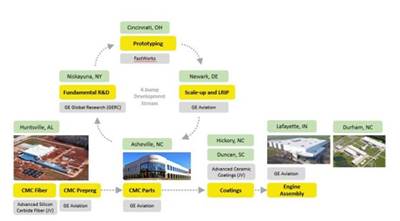

WatchVertically integrated CMC supply chain

GE Aviation's new ceramic matrix composite supply chain includes fiber, prepreg and unprecedented parts production facilities, plus a strongly tied 4-bump development stream.

Read MoreGE Aviation's CMC parts facility in Asheville, NC

CW's first-hand look at ceramic matrix composites production.

Read MorePlant Tour: GE Aviation, Asheville, NC, US

An avant-garde approach to unprecedented CMC parts production.

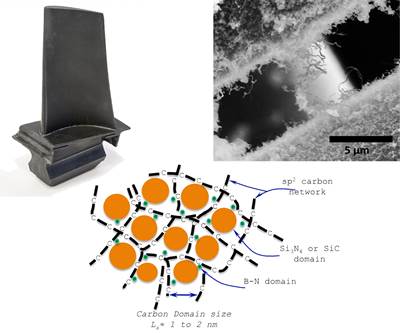

Read MoreCeramic matrix composites: Hot engine solution

Disruptive designs for composites operation in 1093°C zones.

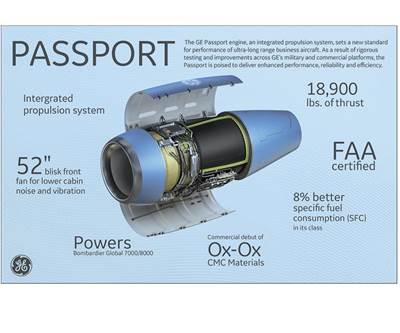

Read MoreCommercialization of CMCs and developments for next-gen performance

As industrial production of parts begins, new developments offer promise for higher-temperature and more damage-tolerant ceramic matrix composite (CMCs).

Read MoreGE Aviation making progress on CMC facilities in Alabama

$200 million Huntsville operation to produce up to 20 metric tons of material a year.

Read MoreThree new 3D printing technologies for composites

Fiber-reinforced composite tooling, ceramic matrix composites (CMCs) and woven fiber composites are all now the realm of 3D printing.

Watch