Ceramic Matrix Composites

GE Aerospace awarded demonstration contract for NASA HyTEC project

Turbofan engine small core technology development with CMC-coated components targets enhanced fuel efficiency in single-aisle aircraft by mid-2030s.

Read MoreBio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

Read MoreDITF Denkendorf advances sustainable carbon fibers, oxide fibers for CMC and more

The German Institutes of Textile and Fiber Research are targeting more sustainable carbon fiber via low-pressure stabilization and bio-based precursors, and working with Saint-Gobain to commercialize oxide ceramic fibers for CMC.

Read MoreRATH works with InVECOF project to mature oxide fiber production in Europe for CMC

Producer of Altra ceramic staple fibers aims to scale up continuous Ox fibers to compete with Nextel 610 and 720, and with its partners, offer improved fibers with creep resistance for higher temperature CMC applications.

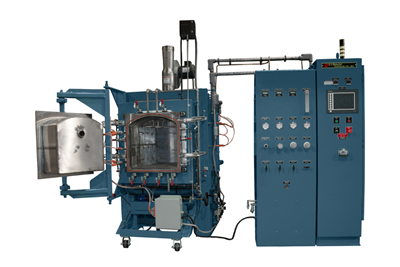

Read MoreL&L Furnace deliver atmosphere-controlled retort furnace for CMC

XLC3348 furnace model is tailored to produce lightweight CMC components for Midwestern aerospace manufacturer.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreHigh-temperature polyimide and CMC composite structures

CAMX 2023: Composites Horizons LLC showcases capabilities in high-temperature composite structures and assemblies manufacturing, including polyimides and CMC.

Read MoreLucideon, NCC partner to develop next-gen CMC solutions

This close collaboration will develop, analyze and evaluate advanced materials and applications to support the emerging demand for materials that can survive high-temperature, extreme and harsh environments.

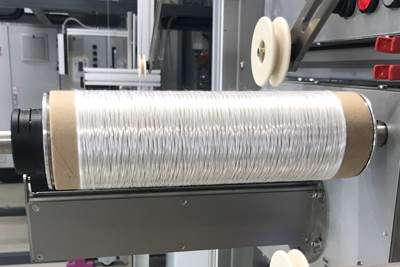

Read MoreAMRC fiber handling expertise aids CMC coating technology

The CICSiC project successfully developed equipment and processing know-how associated with the uniform, continuous coating of SiC-based CMC, to bring down cost, and improve performance and reliability for new designs, applications.

Read MoreCollaboration between NCC, UKAEA to develop fusion-grade SiC/SiC composites

High-volume composites development for future fusion power reactors under HASTE-F program accelerates U.K.’s net-zero energy generation, drives transformation in industries that use high-temperature CMCs.

Read More