Ceramic Matrix Composites

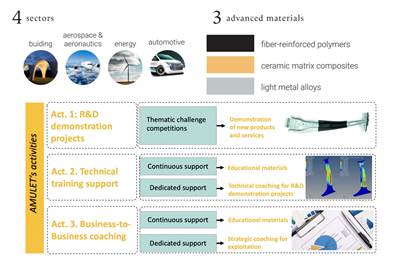

AMULET project aims to create new value chains for fiber-reinforced polymers and CMCs

R&D demonstration projects targeting current challenges in auto, aero, energy and building will be developed to reach TRL7 with the goal of accelerating industrial use of advanced lightweight materials.

Read MoreMag7 Technologies offers advance licensing for graphene CMC technology

The company’s process produces graphene-enhanced ceramic precursor for use in ceramic matrix composite (CMC) applications.

Read MoreGE Aviation reaches advanced manufacturing milestone for CMC and AM jet engine components

This past July, two sites, Asheville, N.C., and Auburn, Ala., shipped their 100,000th CMC turbine shroud and 100,000th additively manufactured fuel nozzle tip respectively.

Read MoreCAMX 2021 exhibit preview: Revolution Composites

Revolution Composites’ triaxial braiding process uses a wide range of fibers for for thrusters, nozzles and conical shapes in spaceflight.

Read MoreResearchers work to prove out ultra-high-temperature CMC for NASA Interstellar Probe study

A recent study by Johns Hopkins and Advanced Ceramic Fibers LLC worked toward ceramic matrix composites able to withstand up to 3,500°C for space heatshields.

Read MoreCFM RISE program targets composites, additive manufacturing and hybrid electric

GE Aviation, Safran program targets more than 20% lower emissions, 100% compatibility with sustainable and hydrogen fuels, with a technology roadmap detailing CMC, composite fan blades and more.

Read MoreAxiom Materials CerFace AX-8810 surface film improves outer finish of CMC components

Surface film protects exposed fibers and minimizes surface roughness of CMC components for operating temperatures of up to 1,093ºC.

Read MorePratt & Whitney to produce advanced metal and CMC turbine airfoils in North Carolina

New 1 million-square-foot production facility follows CMC R&D center and publicized strategy for next-gen engines.

Read MoreWSU-NIAR receives $13.5 million from Air Force for advanced composites research

Additional funding extends NIAR’s Modeling for Affordable, Sustainable Composites (MASC) research program, which will develop technologies to optimize digital twin data.

WatchClean Sky 2 announces program updates

Clean Sky 2 highlights several ongoing and recently completed composites-related projects including a small aircraft ground cabin demo, simulation tools and a CMC inter turbine duct.

Read More