Ceramic Matrix Composites

Highlights from 10th Intl. CFK Valley Stade Convention 2016

Annual conference featured new carbon composite technologies.

Read MoreGE Aviation breaks ground on CMC facilities in Alabama

The two adjacent factories in Huntsville will mass-produce silicon carbide (SiC) materials used to manufacture ceramic matrix composite components (CMCs) for jet engines and land-based gas turbines for electric power.

Read MoreGE Aviation to build ceramic matrix composite factories

One plant will be the first U.S.-based factory to produce SiC ceramic fiber on a large industrial scale.

Read MoreAeroengine Composites, Part 2: CFRPs expand

Proven in fan blade/case applications, carbon fiber-reinforced polymers migrate to previously unanticipated destinations nearer the engine “hot zone.”

Read MoreAeroengine Composites, Part 1: The CMC invasion

As pressure for commercial aircraft fuel efficiency continues to mount, ceramic matrix composites evolve as they battle metals for application in the engine hot-zone and elsewhere.

Read MoreCFM LEAP-1B engine begins flight test program

The engine features extensive use of carbon fiber and ceramic matrix composites.

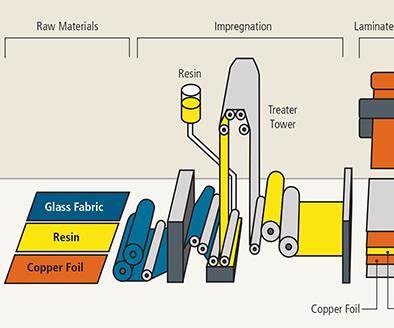

Read MorePrinted circuit boards: A mobile market

Glass fiber/epoxy prepregs have dominated the mammoth PCB market for decades. Will that continue in a time of great change?

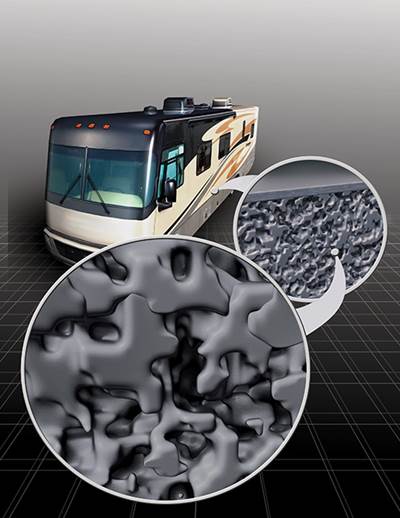

Read MoreMass reduction for mass appeal: FRPs and CMCs in RVs

Composites save weight, speed assembly, improve aesthetics and diminish warranty service and promote sales.

Read MoreJEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

Read MoreHighlights: JEC Europe 2014

Composites enable high performance and lower weight in washtubs, wheelchairs and engine exhaust cones. Plus new, ultralight materials.

Read More