Compression Molding

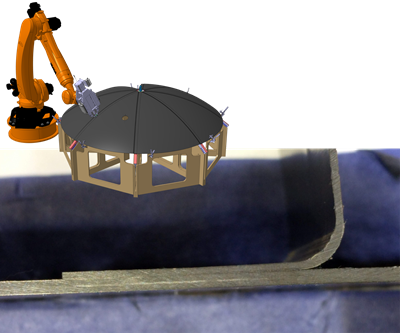

Rockwood Composites doubles capacity for large components

The company has added a third large press for producing complex composite components incorporating multiple elements and complicated geometries.

Read MoreCAMX 2018: Exhibit previews

If you are headed to CAMX 2018 Oct. 15-18 in Dallas, TX, you can catch a glimpse of some of the products and technologies you are likely to find on the exhibit hall floor.

Read MoreStoner Molding Solutions acquires Meguiar’s Paste Wax Mold Release products

Stoner will begin distributing M0811V2 Maximum Mold Release Wax, M8711 High Temp Mold Release Wax and M8811 Universal Mold Release Wax under its new Miracle Gloss brand.

Read MoreSustainable, inline recycling of carbon fiber

Shocker Composites and R&M International are developing a supply chain for recycled CF with zero knockdown vs. virgin fiber, lower cost and, eventually, lengths delivering structural properties close to continuous fiber.

WatchCAMX 2018 preview: Norplex-Micarta

Norplex-Micarta (Postville, IA, US) is featuring its recently introduced EnableX, a continuous fiber prepreg that can be co-cured in a multimaterial molding system to produce near net shapes.

Read MoreCAMX 2018 preview: French Oil Mill Machinery Co.

French Oil Mill Machinery Co. and TMP, A Division of French, are featuring a self-contained, three-press system with one central press controller for compression molding composite medical parts.

Read MoreNew horizons in welding thermoplastic composites

Latest developments in qualification, production and applications for aerospace and automotive.

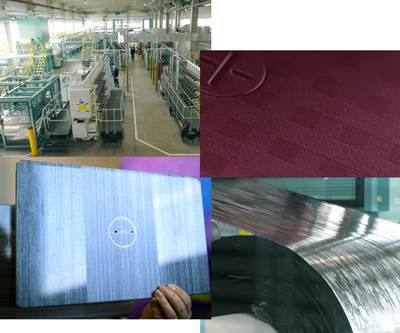

Read MoreCovestro establishes CFRTP as "a material class of its own"

Trademarked as Maezio, Covestro claims continuous fiber reinforced thermoplastic composites “outperform metals,” offering advantages in aesthetics, lightweight and robust process flexibility.

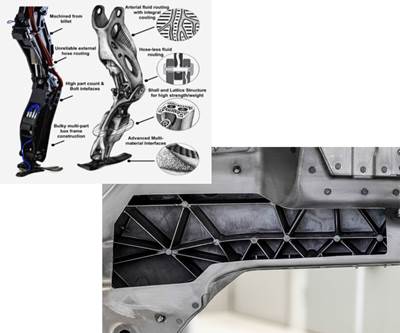

Read MoreConnecting the Dots: Generative design, bionic structures and future composites

The trend shows cast and 3D printed metal, but fiber-reinforced composites offer the potential for multifunctional structures.

Read MoreReinforced phenolics: Still disruptive after all these years

Fiber-reinforced phenolics could be a key enabler of a coming automotive industry disruption.

Read More