CAMX 2018: Exhibit previews

If you are headed to CAMX 2018 Oct. 15-18 in Dallas, TX, you can catch a glimpse of some of the products and technologies you are likely to find on the exhibit hall floor.

- Cutting/Kitting

- Automotive

- Sheet Molding Compound

- Pultrusion

- Carbon Fibers

- Out of Autoclave

- Workforce Development

- Molds/Tools

- NDI

- Machining/Drilling

- Materials

- Fabrics/Preforms

- Adhesives

- ATL/AFP

- Weaving

- Processes

- Epoxies

- Resins

- Thermoplastics

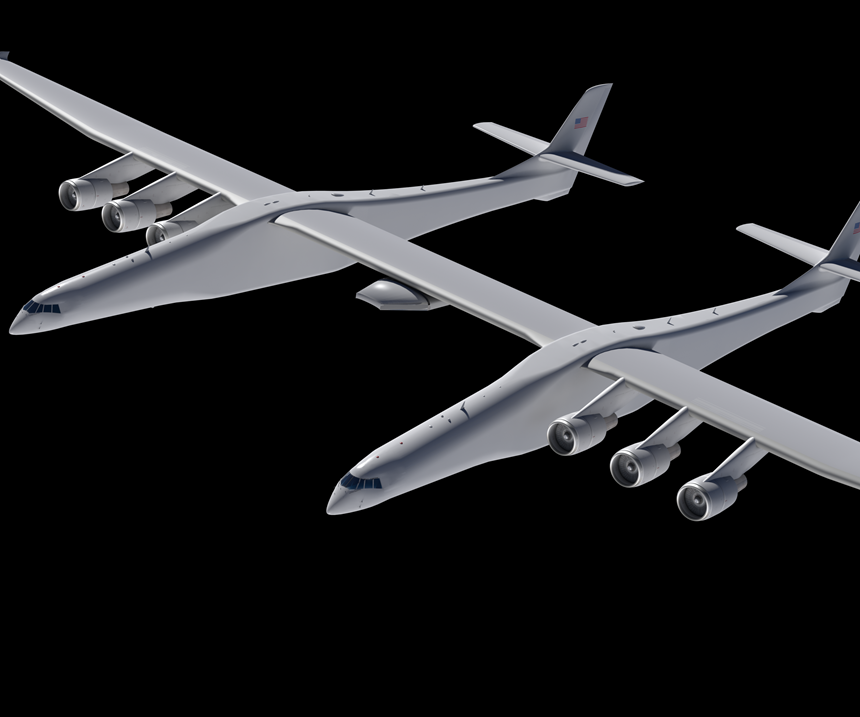

- Aerospace

- Reinforcements

- Design & Tooling

- Autoclave

- CAMX

- Hi-Temp Resins

- Compression Molding

- Ketones

- Additive Manufacturing

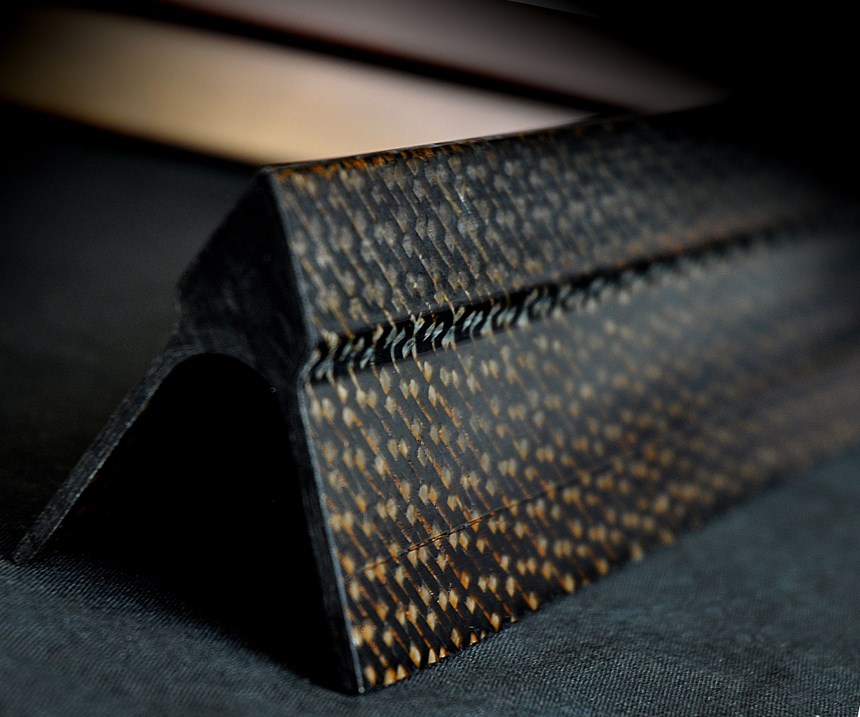

- Braiding

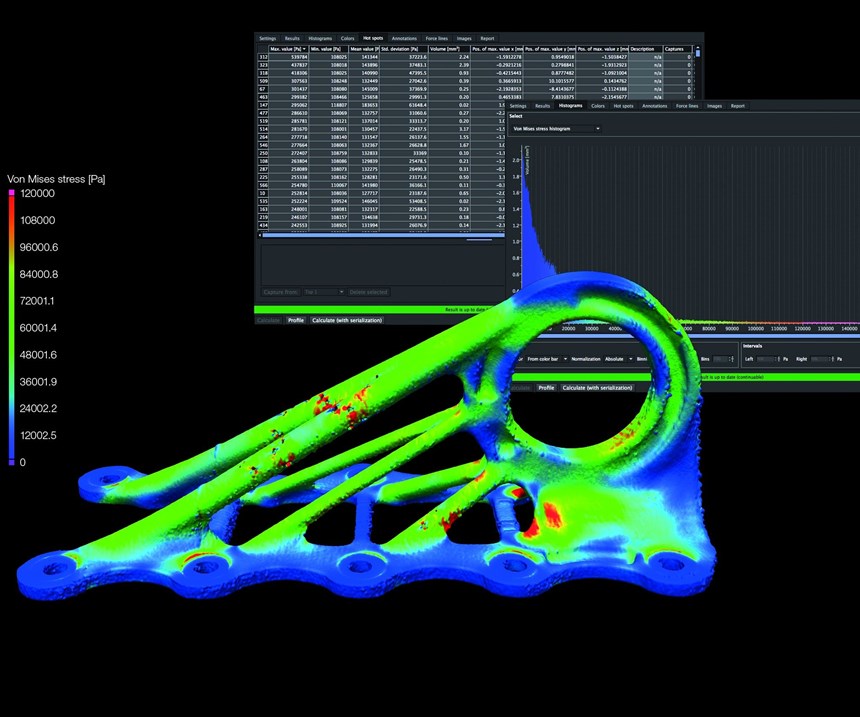

- Design/Simulation

- RTM

- Curing

- Infusion

- Materials Testing

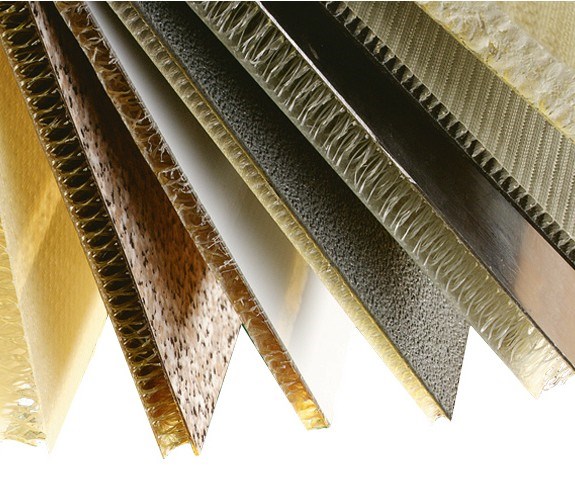

- Core

- Filament Winding

CAMX 2018, Oct. 15-18 in Dallas, TX, US, is North America’s largest composites trade show and conference. The exhibit hall will feature the very latest in materials, equipment, software and services for all types of composites design, engineering and manufacturing. Below is a preview of just some of what you will find at the show. We hope to see you there.

- A&P Technology: Engineered braided fabrics designed to enable cost savings

- A. Schulman: Sheet molding compounds

- Abaris Training Resources: Composites manufacturing and repair training services.

- Accudyne Systems: Customized automation equipment for intermediary materials, preforms and finished parts

- Airtech: Tooling prepreg, consumables for vacuum bag molding

- Andara: Styrene-free NOVOC resins for coatings, composites and other applications

- ARM Automation: Fully automated solutions for cutting table clearing, ply inspection, kitting and ply layup

- ATSP Innovations: Ultrahigh-temperature resins for coatings, composites and stock shapes

- Autometrix : Automated cutting tables and associated systems

- Bally Ribbon Mills: 3D woven joints and thermal protection systems

- BriskHeat: Fexible heating, insulating and temperature control solutions

- C. A. Litzler: Thermoplastic prepreg machines

- Center for Integration of Composites into Infrastructure: FRPs for infrastructure applications

- CGTech: Machine control and software software solutions

- Cold Jet: Dry-ice cleaning systems

- Composite Development Centre of Québec: Applied research services, technical assistance

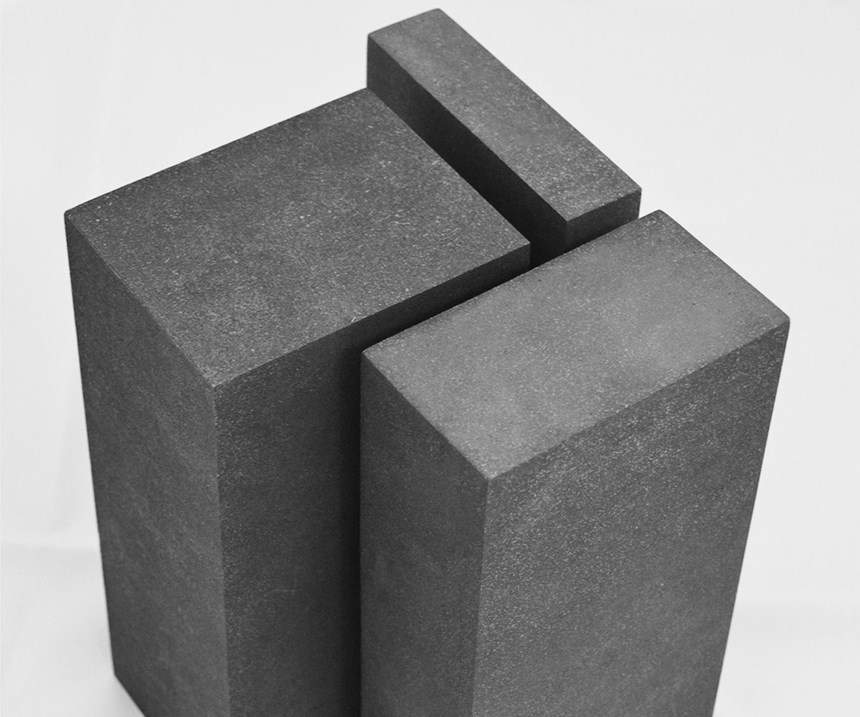

- Compotool: Inorganic tooling board made from calcium silicate

- CoreLite: Core coating solutions

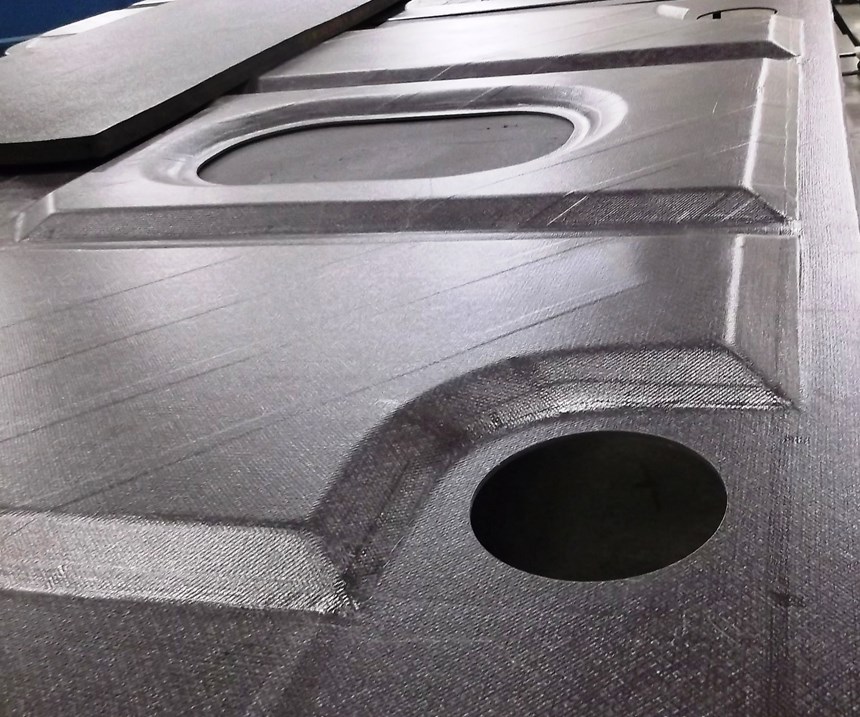

- Diversified Machine Systems: Hybrid 3-axis additive/subtractive machining

- Dixie Chemical: Anhydride curing agents, reactive diluents, tougheners, resins and bio-based raw materials

- DWA Aluminum Composites USA: Aluminum metal-matrix composites

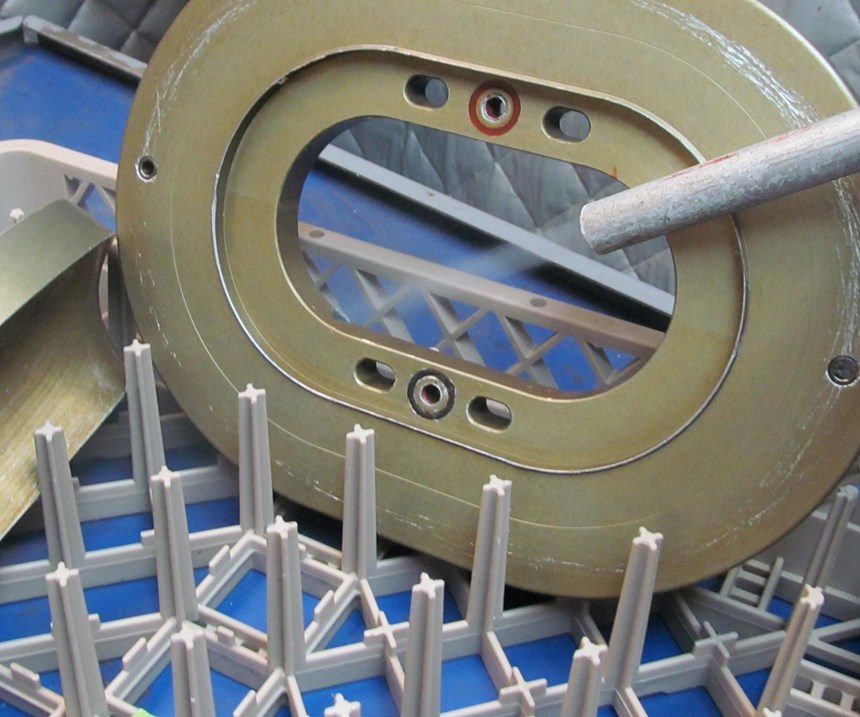

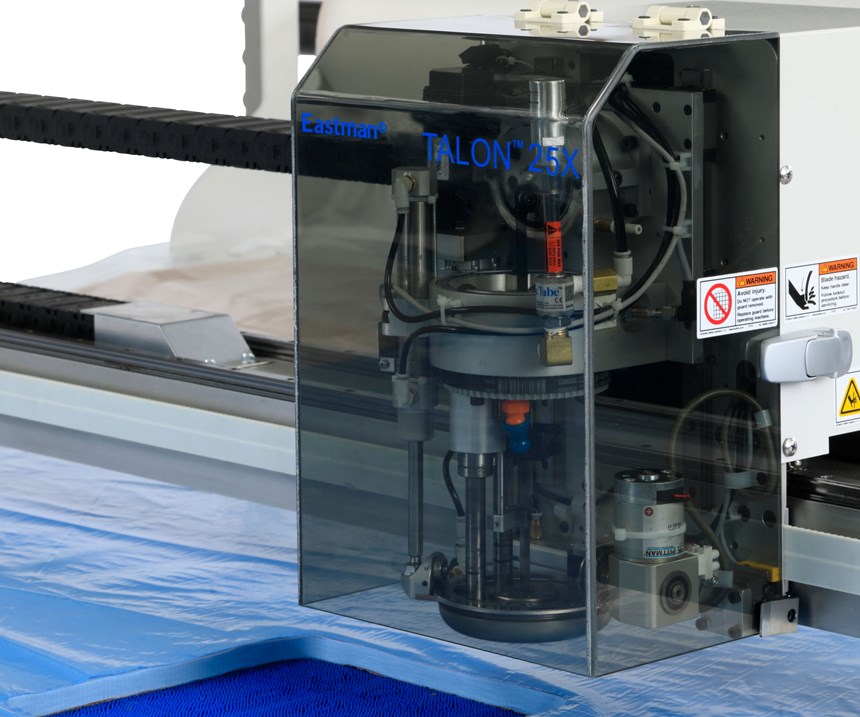

- Eastman Machine: Cutting tables, ply management systems

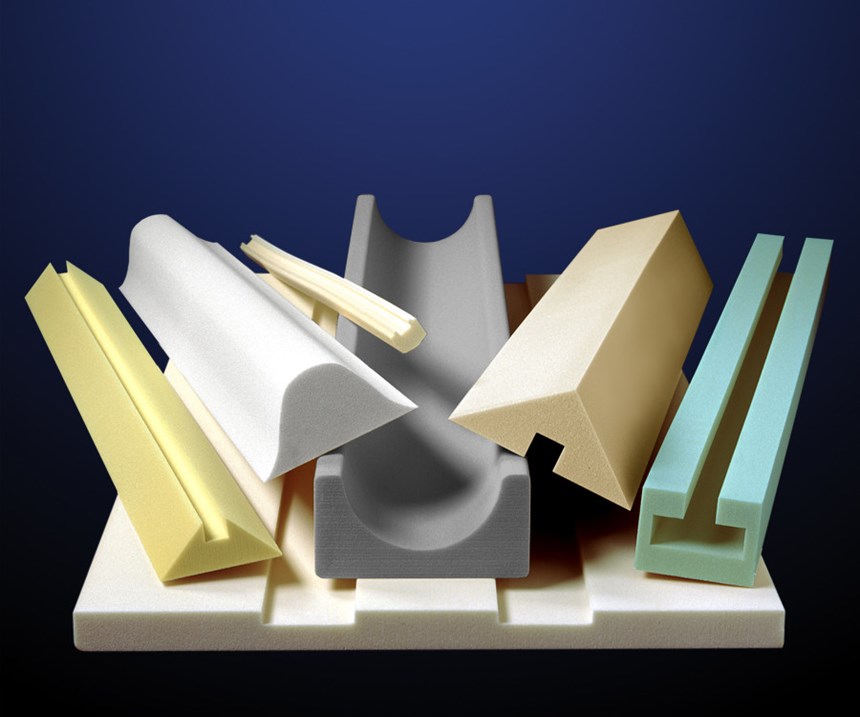

- Elliot Co. of Indianapolis: Rigid unfaced polyisocyanurate (urethane) closed cell foam cores

- Entec: Filament winding systems

- Eurovac: Dust removal systems

- Fiber Dynamics: Design and fabrication services using resin transfer molding (RTM) and lost core RTM processes

- French Oil Mill Machinery Co.: Compression molding machines

- General Photonics: Optical transmission scanner for nondestructive testing

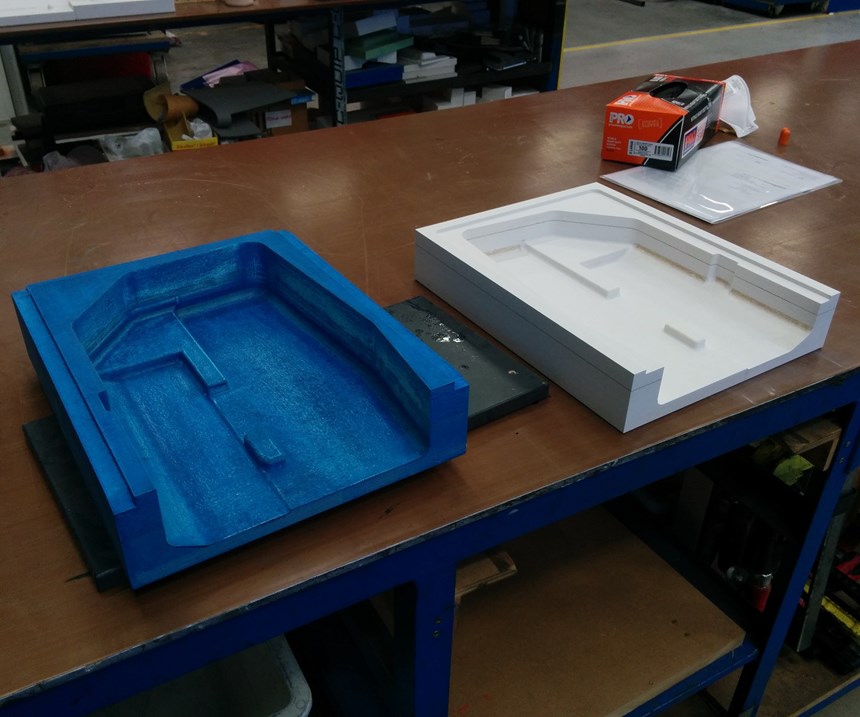

- General Plastics: High-temperature, low-CTE tooling board

- Gerber Technology: Cuttings tables and cutting table software

- HEATCON Composite Systems: Composites repair equipment

- Henkel: Mold releases, liquid shims, lightning strike protection, surfacing films, paste adhesives, syntactic pastes and films, adhesive films, low-viscosity composite resins

- Hennecke: Polyurethane composites fabrication solutions

- Heraeus Noblelight America: Infrared emitters for composites curing

- Hexcel: Additive manufacturing technology technologies, carbon fiber, prepreg, resin solutions.

- IDI Composites International: Polyester/vinyl ester-based bulk molding compounds, sheet molding compounds

- IKONICS: Abrasive machining solutions

- Inman Mills: Thermoplastic yarns and fabrics

- International Thermal Systems: Out-of-autoclave curing systems

- Janicki Industries: Carbon fiber composites design, tooling, prototyping, fabrication services

- Kent Automation: Pultrusion systems

- KRÜSS: Analyzers for quality control of pretreated or coated surfaces

- L&L Products: Room-temperature cure adhesives for FST applications

- L.S. Starrett Co.: Motorized digital test frames

- Langzauner: Hydraulic presses for thermoplastic and thermoset material processing

- Leadgo-tech: Vacuum bagging process materials

- LEWCO: Batch ovens, conveyor ovens, drum ovens, tote ovens, hot boxes, drum heating tunnels, large field-assembled ovens and high-temperature furnaces

- Mafic: Basalt fibers

- Magnolia Advanced Materials: Ultralow-density syntactic foam for core splicing

- Matrix Composites: Designer and manufacturer of high-performance composite components and assemblies

- Maxcess: Distributor of products from Fife, Tidland, MAGPOWR, Webex, Valley Roller, Menges Roller and Componex

- METYX: Multiaxial reinforcements, carbon fiber reinforcements, RTM reinforcements, woven reinforcements and vacuum bagging products

- Montalvo: Closed-loop, modular, individual tow-tension control systems

- Morrow Hill: Property leasing, development and purchase solutions

- MSC Software: Additive manufacturing design optimization software

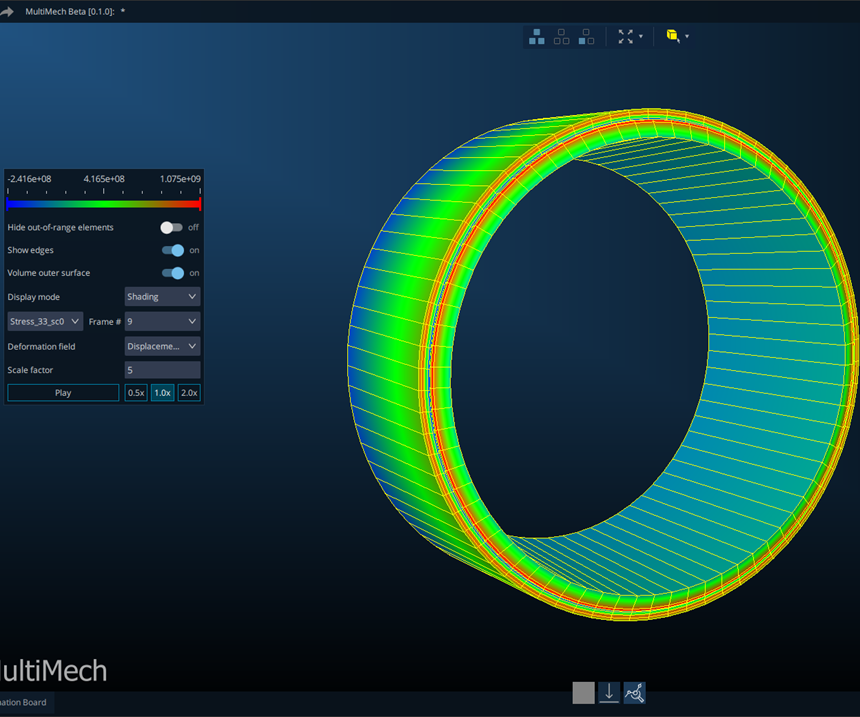

- MultiMechanics: Composite tube and pressure vessel optimization tool

- Norplex-Micarta: Continuous fiber prepreg for near net shapes

- Nor-Ral: Composite tools and parts fabrication

- Olin: Epoxy resin systems

- OMAX: Waterjet cutting systems

- Pacific Coast Composites: Composites distribution services

- Parabeam: 3D E-glass and hybrid fabrics, fiberglass sandwich systems

- Piercan USA: Natural rubber latex bladders for composites fabrication

- Porcher Industries : Fiber reinforcements for aerospace and automotive applications

- Pultrex: Standard and bespoke filament winding, pultrusion and auxiliary equipment

- Quartus Engineering: Engineering services for the design, analysis and manufacture of aerospace, mechanical and optical systems using computer-aided technologies

- Renegade Materials/Maverick: Non-MDA, polyimide-based, high-temperature prepregs and adhesives

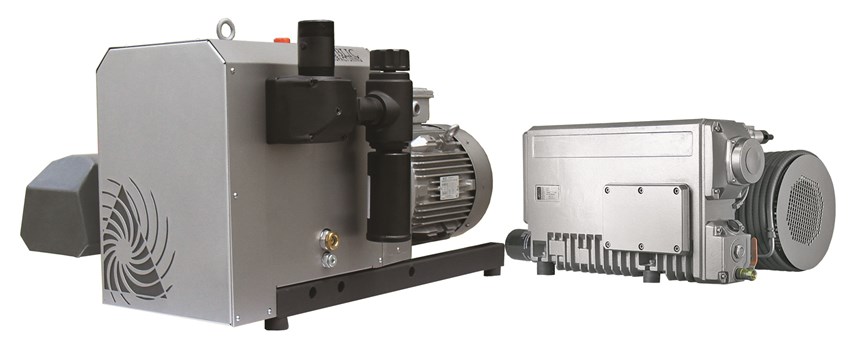

- Republic Manufacturing: Vacuum pumps for composite manufacturing operations

- RobbJack: PCD drills for machining composites

- Rock West Composites: Development and manufacture of composite products, components and assemblies

- Roth Composite Machinery: Filament winding and prepreg solutions

- SAT Plating: Plating solutions for carbon fiber composites and high-performance PEEK and Ultem materials

- Schmidt and Heinzmann: Cutting, dosing, distribution of fiber reinforcements

- Scott Bader: Adhesives, resins, gelcoats and matched tooling systems

- Smartech: Reusable vacuum bagging materials

- Specialty Materials Inc.: Boron monofilament and prepreg, silicon carbide monofilament (SiC).

- Stat Peel: Nanofiber detection system

- Structural Composites: Composites design and fabrication services.

- Sumitomo: Polyethersulfone (PES), liquid crystal polymer (LCP) and high-temperature alloy resins

- TE Wire & Cable: Thermocouple assemblies for high-temperature aerospace autoclave applications

- TenCate Advanced Composites: Thermoplastic and thermoset composite solutions

- TFP: Nonwovens for composites surface finishing

- Thermwood: Large-format additive manufacturing and machining

- Thinky USA: Vacuum mixers

- VitaFlex: Composites fabrication safety equipment

- Volume Graphics: Metrology software systems

- Wabash: Standard and custom compression machines

- Westmoreland Mechanical: Non-metallic and composite materials testing services

- Wisconsin Oven: Electrically heated, gas-fired and indirect gas-fired curing batch ovens

- Zwick: Tooling, grips and fixtures interlaminar shear strength testing

Related Content

PUR composite sandwich panels for 3D automotive parts, high-volume panels and more

At its U.S. sites, Ascorium produces glass fiber/PUR 3D parts via semi-automated molding, high-volume flat panels via a continuous line while working toward bio-based PUR and recycling.

Read MoreHyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

Read MoreTeijin Automotive innovates core technologies for body panels

The company’s latest Hexacore and Foam-A-Core products have been developed to meet needs for high impact, fast cycle times and low moisture absorption.

Read MoreA new generation of PP foam core for lightweight truck trailers, RVs

Extruded PP (XPP) foam core offers lightweight, high-performance monomaterial panels that are easily recycled for truck flooring, sidewalls or cabinet/furnitureboards as the transportation industry seeks a replacement for plywood.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More