Core

Leveraging motorsports composites for next-gen rotorcraft

FastCan consortium integrates hollow, solid and cored CFRP into single-cure, single-piece canopy for reduced weight and cost.

WatchCosiMo: Smart thermoplastic RTM process demonstrated for battery box cover challenge simulator

Project uses network of DEA, temperature/pressure and ultrasonic sensors plus digital simulation and AI modeling to monitor and optimize injection of caprolactam into complex glass fiber preform and in-situ polymerization of PA6.

WatchIndustrial-scale wave energy system enabled by mobile filament winding

Sweden-based CorPower Ocean designed its 9-meter-long, filament-wound GFRP buoy prototype for high-efficiency, durable wave energy generation and fast, on-site manufacture.

WatchStratasys, Champion Motorsport team up to test 3D-printed core technology

Stratasys proves out carbon fiber-wrapped, printed core for toolless, customizable manufacture, on aerodynamic prototype and production parts for a winning racecar.

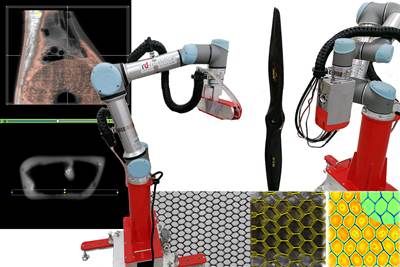

Read MoreRobotic computed tomography – removing NDT barriers for composites

Radalytica uses collaborative robots, ultra-sensitive X-ray photon detectors and the ability to combine CT with ultrasound, surface profiling and other inspection methods to optimize composites part quality, production and reduce cost.

WatchCAMX 2021 exhibit preview: Armacell

Armacell highlights its eco-friendly, recycled PET bottle ArmaPET foam solutions for composite parts in a variety of end markets.

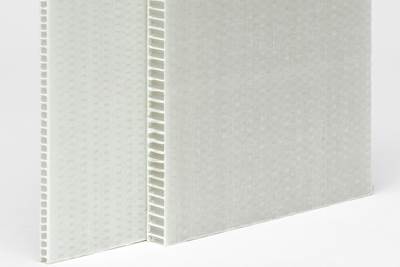

Read MoreThermHex, EconCore invest in automated production for PP honeycomb sandwich, recycled PET products

Targeting recycled and high-performance thermoplastic options, automated R&D lines increase volume and speed for honeycomb, sandwich panel and finished part production.

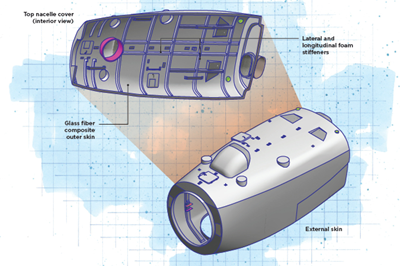

Read MoreOptimizing a wind turbine nacelle cover to meet LCOE demand

Suzlon Group redesigned a composite nacelle cover with in-situ molded stiffeners to reduce manufacturing and material costs while maximizing part performance.

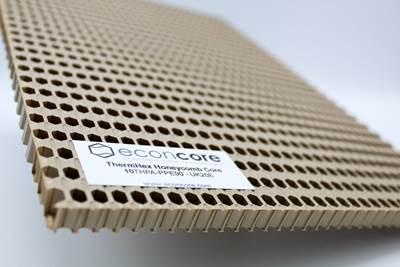

Read MoreEconCore thermoplastic honeycomb cores deliver high-heat performance, facilitates recyclability

Honeycomb cores incorporate Sabic NORYL GTX resin for improved dimensional stability, lower water absorption and demonstration of thermoset composite skin compatibility.

Read MoreCobra International rapidly scales up Radinn glass fiber electric surfboards

Cobra manufacturing platform to deliver 300 composite boards per month, with 25% weight savings, tight tolerances, detailed QC and documentation records.

Read More

.jpg;maxWidth=300;quality=90)