CosiMo: Smart thermoplastic RTM process demonstrated for battery box cover challenge simulator

Project uses network of DEA, temperature/pressure and ultrasonic sensors plus digital simulation and AI modeling to monitor and optimize injection of caprolactam into complex glass fiber preform and in-situ polymerization of PA6.

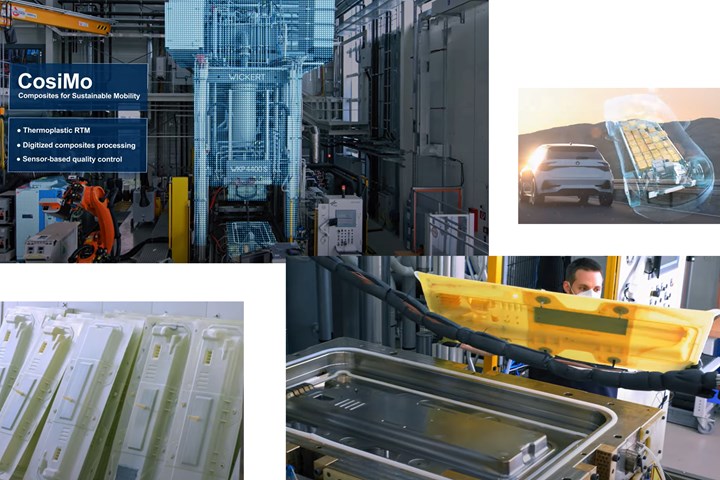

Photo Credit: Still images extracted from the DLR project video ©DLR, images and video by Marcus Lange Videograf.

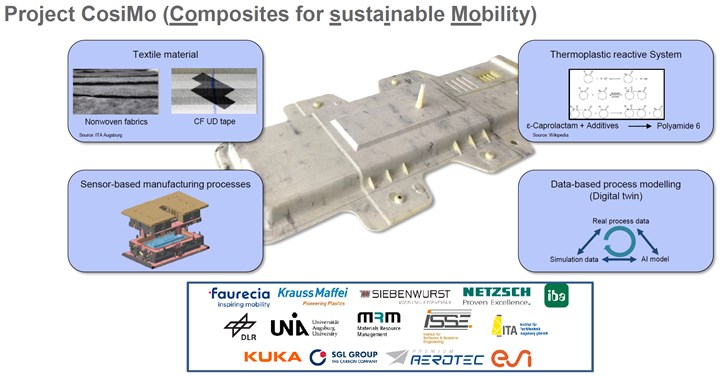

The “composites for sustainable mobility” (CosiMo) project was launched in 2018 by Faurecia Clean Mobility (Nanterre, France) to develop a smart thermoplastic composite resin transfer molding (RTM) process using a comprehensive sensor network including data from an intelligent mold as well as machine data from an injection machine and hot press. The project will be completed by the end of 2021 and CosiMo partners have gained knowledge and experience with closed-loop control combining real-time sensor data with material parameters from lab data and simulation data. CosiMo is funded by the Bavarian ministry of economic affairs, regional development and energy within the Campus Carbon 4.0 program.

The demonstration part, measuring 1,100 millimeters long and 530 millimeters wide was designed by Faurecia Clean Mobility’s research center in Augsburg, Germany. The goal was to explore material and process limitations, including metal and foam core, complex geometry, various radii and thicknesses varying from 2.5 to 10 millimeters. Glass fiber nonwoven fabrics up to 1,000 grams/square meter were provided by the Institute for Textile Technology (ITA) facility in Augsburg. Glass fiber noncrimp fabrics (NCF) and carbon fiber unidirectional tapes for local reinforcement were also investigated. The glass fiber materials allow for use of recycled fibers from end-of-life (EOL) composite parts.

The T-RTM demonstration battery box cover challenge part being demolded at DLR ZLP. Photo Credit: DLR Center for Lightweight Production Technology, CosiMo project

Based on the part design by Faurecia Clean Mobility and the preforming tool manufactured in Augsburg, the T-RTM process in CosiMo used a KraussMaffei (Munich, Germany) 3K (three-component) injection machine. The process is a derivative of a 2K process patented by Tecnalia (Donostia-San Sebastián, Spain) which was demonstrated by KraussMaffei at the 2016 K show in Düsseldorf, Germany. The 3K injection machine was combined with a 4,400-kilonewton Wickert (Landau in der Pfalz, Germany) hot press in which a steel RTM tool was installed. The RTM tool was manufactured by Siebenwurst in Dietfurt, Germany.

The main goal of the project was to investigate full automation and sensor-based process control for a single-step T-RTM process using a sensored RTM mold and hot press. Roughly 100 demonstration parts were fabricated in this project by the German Aerospace Center (DLR) Center of Lightweight Production Technologies (ZLP, Augsburg). “These parts, made with varying reinforcements, were high-quality and demonstrated high reproducibility,” says CosiMo manufacturing project leader at DLR ZLP, Jan Faber.

As project leader for the “HAP 3 – Intelligent Tooling” work package, DLR ZLP also provided the key interface between basic material characterizations in the “HAP 1 – Tailored Nonwovens” and “HAP 2 – Reactive Systems” work packages and the “HAP 4 - Data-driven Process Control”.

Sensor network

More than 70 sensors were integrated into the steel RTM tooling to monitor process parameters during resin injection and in-situ polymerization. This network comprised a variety of sensors including combined pressure/temperature sensors by Kistler (Winterthur, Switzerland), dielectric sensors by Netzsch (Selb, Germany) and ultrasonic sensors developed by the University of Augsburg. The latter are based on concepts of widely-used commercial piezoelectric sensors, but modified for the high temperatures and in-mold integration requirements of thermoplastic composites processing. Material, process and machine data was collected, processed and then published to the machine learning platform by a central data acquisition system supplied by iba AG (Fürth, Germany).

Process simulation and optimization

The sensor network enabled monitoring of resin flow and polymerization, as well as tracking of part parameters in the complex tool geometry. Process parameters such as temperature and pressure were used to analyze real-time resin filling and polymerization behavior.

Wickert heated press and T-RTM equipment setup at DLR ZLP. Photo Credit: DLR Center for Lightweight Production Technology, CosiMo project

Process parameter data from sensors was also used to optimize process simulation models. Based on a previously defined manufacturing demonstrator, sub-processes of the part manufacturing (e.g., resin filling simulation) and characteristics of the polymerized component (e.g., distortion simulation) were modeled with ESI PAM composites software (ESI Group, Rungis, France). DLR ZLP compared these simulation results with real process data to optimize the T-RTM process, as part of the HP3-Workpackage’s activities.

The project then developed automated and simulation data-driven process control based on machine-learning methods. The Institute for Software & Systems Engineering (ISSE, prof. Reif) within the University of Augsburg generated machine-learning training data and developed artificial intelligence (AI) models predicting the polymerization status as well as the time required for polymerization, and potential issues during resin injection, filling and polymerization sub-processes. This was done in cooperation with Kuka (Augsburg, Germany), another key partner in the project.

A kinetic model describing the polymerization progress was developed by the Institute of Materials Resource Management (MRM) within the University of Augsburg. Netzsch was also a key collaborator, transferring its knowledge of thermoset process monitoring to thermoplastic process monitoring to help establish the predictive AI models’ ability to predict at which time the PA6 polymerization should be finished and what the polymerization state would be.

Parts fabrication and testing

For parts production, the steel tooling was heated to 170°C and the reactive caprolactam resin components were heated to 120°C. The preform was placed into the mold, which was then closed. After a short dwell to allow the preform to come to mold temperature, the caprolactam monomer was injected, which took 20-25 seconds. Process simulation showed in-situ polymerization required 5.7 minutes after injection for 98.5% conversion. After this time, the press was opened and the part demolded at 170°C.

DLR ZLP produced roughly 100 high-quality demonstration battery box cover challenge parts for the CosiMo project. Photo Credit: DLR Center for Lightweight Production Technology, CosiMo project

Degree of polymerization was confirmed via infrared spectroscopy, rheometric data and DEA sensor analysis of polymerization. Finished parts were evaluated using nondestructive testing including microscopy, thermography and air-coupled ultrasound. Part quality was correlated with process sensor data and compared to similar glass fiber/thermoplastic parts on the market.

Future development

For DLR ZLP, says Faber, this project has been a success. “We have completed our part and have developed a lot of knowledge about using sensors to achieve fully digital closed-loop control of composites processing,” he says. “For industrial serial production, no one would install so many sensors and that’s not what we would expect. But for this research investigation, this large sensor network was very precise and helped us to have full visibility into the process and material behavior. We could see the local effects in the process in response to variations in part thickness or in the integrated materials, like the foam core.”

He notes that this project has generated a lot of knowledge and sees future potential to apply it to slower RTM and infusion processes, where the risk for part quality issues has been historically very high. Faber will also present CosiMo project developments and results in “Sensor-based process monitoring of in-situ polymerization in T-RTM manufacturing with caprolactam” on Wed., Sep. 29 during the live and virtual event, SAMPE Europe 21 conference, in Session 1, Room 1 – Automotive.

DLR ZLP is also one of three key partners in the Augsburg AI (artificial intelligence) Production Network — founded in January 2021 — which also brings together the University of Augsburg and the Fraunhofer Institute for Foundry, Composites and Processing Technology (Fraunhofer IGCV). As explained by Dr. Markus Sause, director of the AI Production Network and also a CosiMo project researcher developing ultrasonic sensors, “We’re going to extend this blueprint of collaboration that has been highlighted in the CosiMo project to a much larger scale, developing AI technologies for production with a strong focus on composites. Our new 5,000 square meter facility in Augsburg will be opened in 2022 and outfitted with a variety of machines throughout next year, enabling companies to see demonstrations of what AI can do for real processes in a production setting.”

Faurecia Clean Mobility, meanwhile, will extend internally the knowledge gained over the CosiMo project, which is fully aligned to Faurecia’s sustainability strategy and ecological transition. Faurecia would also thank the Bavarian Federal Ministry for Economic Affairs, Regional development and Energy, who has financially supported this research project.

Related Content

Owens Corning initiates review of strategic alternatives for glass fiber business

Owens Corning considers alternative options like a potential sale or spin-off as part of its transformative move to strengthen its position in building and construction materials.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreAl Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More