Defense

The NCC launches first U.K. composites technology forum dedicated to defense

The forum brings together large industry primes, academia and SMEs to facilitate technical exchange and drive innovation for composites technology development.

Read MoreMoving toward portable, digitized composite part repair

Using digital twin technology, American GFM’s portable, automated inspection and scarfing system shows potential for on-site, data-driven composite aircraft part repair.

Read MoreLockheed Martin opens hypersonic strike production facility

Lockheed Martin’s 65,000-square-foot Hypersonic Missile Assembly Building 4 (MAB 4) integrates digital transformation advancements for training and virtual inspections.

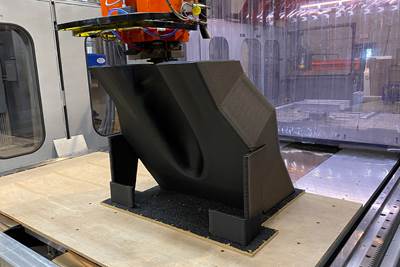

WatchCollaborative Boeing-led project validates large-scale composite AM tooling

The U.S. Navy-funded program demonstrated a large-scale, autoclave-curable 3D-printed carbon fiber composite tool using a Thermwood LSAM machine.

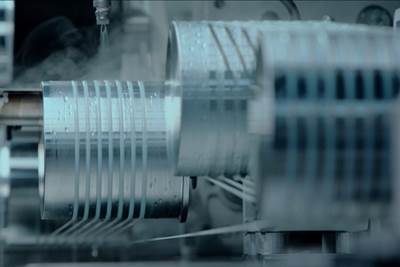

WatchLeonardo invests for the future, establishes pilot carbon fiber plant in Italy in collaboration with MAE

Part of government-supported project to innovate composites, pilot line will be operational in 2022 and enable testing of new precursors and process variations.

Read MorePermali develops fire-resistant systems for naval vessels

Permali has developed Permaglass XGR2/4, a new specialist fire-resistant composite material grade that passes strict Ministry of Defence regulations.

Read MoreBleeding Edge develops blast-resistant composite armor

Bleeding Edge has created a series of customized urethane composite materials that are reportedly capable of resisting the blasts from an IED and M19 landmine, as well as a polymer transparent armor that is ballistic resistant.

Read MoreBoeing to build new factory to produce MQ-25 Stingray

Located in Illinois, U.S., the facility will use digital design and production for the composites-intensive unmanned Navy aircraft.

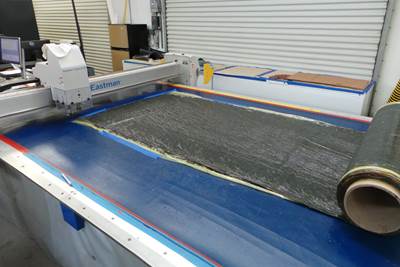

Read MorePrecision Cutting Enables High Speed Composites Molding Process

Automatic cutting of proprietary composite materials is critical for high speed molding of military-grade pressurized camera enclosures.

Read MoreVABO Composites' maritime fire doors pass 60-minute resistance test

FRD60 composite doors cover all B15 and B30 requirements and enhance VABO portfolio for the company’s commercial, superyacht and naval sector client base.

Read More

.jpg;maxWidth=300;quality=90)