Feature

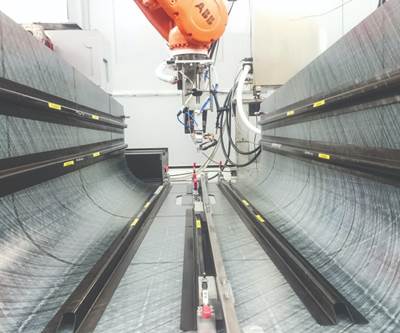

Consolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

Read MoreI want to say two words to you: “Thermoplastic tapes”

Thermoplastic tapes are not new to composites, but they soon will join the primary aerostructures material palette and could be their future.

Read MoreConsolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

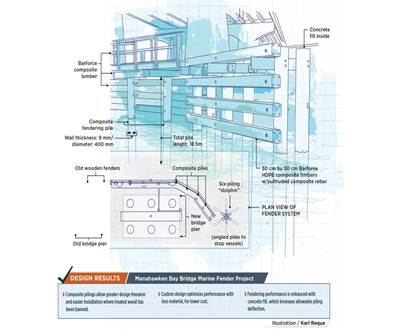

Read MoreComposite fendering piles fit the bill

Composites replace wood in New Jersey marine fender project.

Read MoreComposites and Industry 4.0: Where are we?

As the tide of the Fourth Industrial Revolution rolls in, how will composite manufacturers ride the wave?

Read MoreReconfigurable tooling: Revolutionizing composites manufacturing

Shape-changing molds eliminate tooling for large 3D panels while automated assembly fixtures go modular, using metrology to reduce cost and shimming.

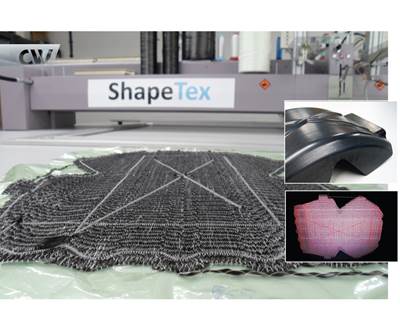

Read MorePreforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

Read MoreSMC: Old dog, more tricks

In the sheet molding compound renaissance, the advent of new resins and compounds are broadening the definition and application of this versatile family of composites.

Read MorePreforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

WatchComposites recycling: Gaining traction

Recycling of carbon fiber, glass fiber and — at last — resins, is growing as new players enter the space.

Read More