Besting Big Ben: A Marvel in Makkah

Composite design makes possible the world’s largest clock and tallest clock tower.

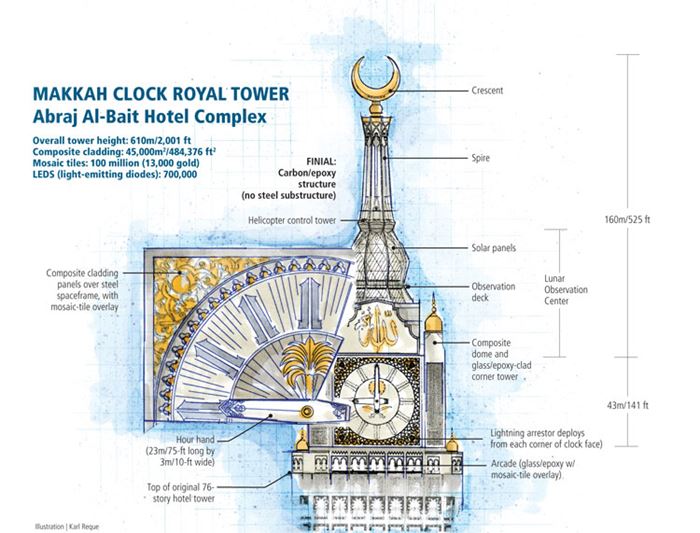

Rising above Islam’s holiest city, the 610m/2001-ft tall Makkah Clock Royal Tower is the focal point for the nearly complete Abraj Al-Bait hotel complex opposite the Grand Mosque of Makkah (Mecca) in Saudi Arabia. A key part of the Development of King Abdul Aziz Endowment (DOKAAE) project, devised to upgrade the mosque environs, the clock tower is the world’s largest — almost five times the size of London’s Big Ben.

When Premier Composite Technologies (PCT, Dubai, United Arab Emirates) was tasked by lightweight-architecture specialists SL-Rasch (Leinfelden-Echterdingen, Germany) to build and install the clock, it came well prepared. Previously, PCT had fabricated composite protection flaps for mechanized umbrellas (see bottom photos, at right) and, earlier, 27 fiberglass sliding domes for the Holy Mosque of the Prophet in Al-Madinah (Medina), Saudi Arabia, as well as composite domes up to 42m/138-ft in diameter for showpiece buildings elsewhere in the Middle East and Asia.

PCT’s managing director, Hannes Waimer, credits the failure-free performance of these structures, in part, to detailed design and testing performed by the SL-Rasch/PCT team. Paired on many projects, beginning with the sliding domes in 1988, PCT and SL-Rausch nevertheless faced some unusually large challenges in this massive tower. Because it is rectangular — the east and west faces are slightly more narrow (38m/125-ft wide by 43m/141-ft tall) than the north and south faces (43m/141 ft square) — PCT would have to fabricate two different pairs of clock faces, each assembled from hundreds of differently shaped panels, which would be drilled to accommodate a total of 700,000 light-emitting diodes (LEDs) for night-time illumination. Further, the clock would be crowned with a 22m/72-ft diameter, 160m/525-ft tall, crescent-topped finial (see drawing, at right), which would house a Lunar Observation Center. Compounding the difficulty, the hotel was already under construction when Saudi King Abdul Aziz decided that its main tower should be crowned with a clock — the original 76-story structure was not designed to support the 200m/656-ft tall addition. “This is where composites came into play,” Waimer explains. “Composites offered a very light, yet strong construction as well as a fast and economical fabrication process.”

Low weight/high function

To minimize weight, the team designed a steel spaceframe clad with composite panels strong enough to resist wind speeds of 53.8 m/sec (131 mph/211 kmh). Here, PCT enlisted the aid of materials supplier Gurit UK (Newport, Isle of Wight, U.K.) not only to develop composite laminate plans, but also to perform finite element analysis (FEA). The latter confirmed a stiffness-driven design, which pointed to sandwich construction; final materials selection also was influenced by the need to meet British Fire Standard BST476-7 Class I surface flame-spread requirements while maintaining sufficient laminate stiffness and strength in a structure compromised by thousands of LED ports.

“We … had to integrate [the] LEDs into this substructure and then extend them through the cladding to be visible from the exterior,” says Waimer. Gurit’s FEA determined both the local and global effects that the through-holes would have, and PCT verified the predictions via testing.

The clock tower’s scrollwork and other complex, three-dimensional (3-D) ornamentation tested PCT’s ability to keep pace with the client’s construction schedule. This, and the large number and intricacy of the molds, tipped the scale toward wet layup. This decision limited PCT’s core choices. “We looked at using aluminum honeycomb,” Waimer recalls, “but we were not comfortable that it would meet the significant bonding requirements due to our need to use wet layup.” Instead, PCT chose Divinycell P100 polyethylene terephthalate (PET) foam, supplied by DIAB International AB (Laholm, Sweden), because it met mechanical and fire requirements and was compatible with the wet lay/vacuum bag process.

Used in all of the clock tower cladding, the PET core thickness varies from 15 mm to 20 mm (0.6 inch to 0.8 inch) for most panels to as thick as 50 mm/2 inches in the clock tower corners. “We analyzed every part of the building,” says Waimer, “to put in precisely what material was needed, but no excess, in order to save weight.”

Next, he recounts, “We needed to develop an economical method for attaching the panels, which averaged 20m [66-ft] long and 2.5m [8-ft] wide, to the building.” To meet wind load requirements, PCT decided to attach the cladding to the spaceframe using a variety of steel brackets. Solid-laminate flanges, 280 mm/11 inches long were molded into the cladding panels, enabling the cladding to be through-bolted to the brackets.

Working with Stuttgart University (Stuttgart, Germany), SL-Rasch engineered and tested a system for incorporating lightning arrestors into the composite cladding. Further, in each of the tower’s four corners, 3m/10-ft telescoping steel lightning arrestors deploy automatically during storms (see drawing, top right).

Sandwich-construction cladding

The cladding panel skins, 2 mm to 3 mm (0.08 inch to 0.12 inch) in thickness, were mostly 800 g/m² (23.5 oz/yd²) and 1000 g/m² (29.4 oz/yd²), stitched E-glass quadraxials with balanced construction. Small quantities of unidirectional and stitched 0°/90° reinforcements were also used locally where additional properties were needed. Suppliers included a mixture of Chinese and European companies, including Formax UK Ltd. (Leicester, U.K.) and Saertex (Saerbeck, Germany).

PCT selected Gurit’s Ampreg 21FR epoxy with Ultra Slow hardener for the wet lamination resin, which offered structural performance, durability and compatibility with the epoxy adhesives used for secondary bonding of structures. Computer-controlled cutting machines from Aeronaut Elektron (Terrey Hills, New South Wales, Australia) minimized waste in kitting the fabrics and foam, and the fabrics were wet-out using impregnation machines designed and built in-house. After layup, laminates were vacuum-bagged, with some parts cured at room temperature overnight and others cured in an oven to shorten overall cycle time. All cured parts were then placed outside in the sun to achieve a postcure, as Waimer explains, “Some panels are very large, 30m² to 40m² [323 ft² to 431 ft²], fabricated in one piece; so everything must be postcured to ensure the required ... properties.”

Lightweighting the hands of time

More heavily loaded than the cladding panels and each equipped with roughly 3,000 LEDs, the clock faces’ minute and hour hands (3m/10-ft wide, 26m/85 ft and 23m/75 ft long, respectively) needed to be stiff and lightweight to prevent excessive deflection and vibration during service. Heat generated by the LEDs and absorbed by the predominantly black tiled finish in the sun demanded a higher design temperature (85°C/185°F) than the clock faces.

The clock hands are sandwich structures. Skins feature an outer layer of prepregged glass cloth, backed by three to nine plies of Gurit’s WE91-2 prepreg, made from large-tow carbon fiber manufactured by Zoltek Inc. (St Louis, Mo.) and SGL Technologies GmbH (Wiesbaden, Germany). The core is Gurit Corecell T-foam, a styrene acrylonitrile selected because it offers greater rigidity and strength than PET and resists temperatures up to 100°C/212°F. Core density varied from 80 kg/m³ to 130 kg/m³ (5 lb/ft³ to 8lb/ft³), and thickness ranged from 20 mm/0.8-inch to 30 mm/1.2-inch, with another three to nine plies of prepreg on the inner skin. To connect the hands to their steel hubs, 26 plies of prepreg were laid to form a solid laminate up to 21 mm/0.83 inch thick. The clock hands were cured under vacuum bag at 80°C/176°F.

Designed as a self-supporting structure to minimize weight, the finial was driven by a high stiffness-to-weight requirement. “The client wanted to use the inside space, so we could not use a steel substructure here,” Waimer points out. “It would have occupied too much room.” The laminate combines unidirectional, biaxial and, to speed production, multiaxial fabrics made from Toray Industries’ (Tokyo, Japan) T700 carbon fiber.

“The finial was actually not as difficult to mold because it was larger with more gentle curves,” Waimer recalls. “The scrollwork and other decorations on the clock faces required using thinner fabrics because we could not get the heavier textiles into and around the corners, so this slowed fabrication.” Because the finial was wet-layed, the same low-temp Divinycell P100 foam used in the cladding was sufficient. Ultimately, the finial adds only 12 metric tonnes/26,456 lb to the building load.

Analysis, testing and installation

During the past 18 months, PCT has built more than 18,000m² (193,750 ft²) of molds and already has fabricated 60 percent of the project’s 45,000m² (484,376 ft²) composite cladding. Approximately 100 million Italian mosaic tiles have been epoxy-bonded to the tower exterior — including 13,000 made from gold. The reflective tiles not only provide continuity with Middle East architectural styling, but also reduce panel surface temperature and, reportedly, will provide 100-year protection from UV degradation, under which, Waimer contends, “no paint will last even 10 years.”

As CT went to press, all clock tower panels and segments had been fabricated and shipped to the construction site. Waimer hopes to complete installation by the first quarter of 2011. With the finish in sight, Waimer says, “This has been an extremely challenging project, but also a once-in-a-lifetime project.”

Related Content

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=860)

.jpg;width=860)