Materials

Mateenbar GFRP rebar supports concrete sculpture

The Giant, a six-ton sculpture based in United Arab Emirates, comprises FRP rebar to eliminate the risk of corrosion, extend life cycle and maintenance.

Read MoreJoby Aviation advances toward FAA certification, highlights Toray prepreg and Coriolis AFP machines

Joby Aviation aims for FAA Part 135 certificate by end of 2022 and launch of commercial service by 2024 as it completes first production-intent aircraft from its pilot manufacturing facility; composites play a key role.

Read MorePultron Composites implements flexible composite rebar for skate park construction

The $2.6 million redevelopment for a skate park in Gisborne, New Zealand, reinforced its concrete with GFRP rebar, which easily bent to accomodate complex curves and improved construction times.

Read MorePlant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas

Veteran aerostructures Tier 1 transforms into 21st century leader in thermoplastic composites and multiple new markets.

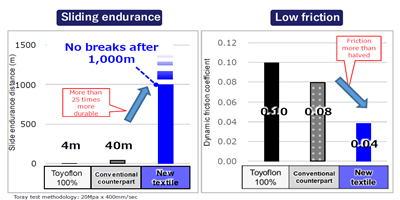

WatchToray develops eco-friendly Toyoflon textile

Toyoflon TM high-strength textile achieves slide durability 25 times greater than existing counterparts, with friction dropping by more than 50%.

Read MoreSHD Composites Group highlights MTB350 bio-epoxy prepreg system

The bio-epoxy system, compatible with nature fiber reinforcements, can be stored at room temperatures of 20°C/68°F for up to six months.

Read MoreBcomp, KTM Technologies brake cover listed as finalist for JEC Innovation Awards 2022

Flax fibers were used to reduce the CO2 emission of the motocross brake cover by 82%, with KTM’s Conexus for effective bonding between thermoset and thermoplastic parts.

Read MoreEvonik invests in modernized Rohacell foam production facility

The new plant, to begin production in April 2022, will ensure delivery reliability for future market demand and feature the latest technology and safety standards.

Read MoreHypetex creates colored carbon fiber covers for IQOS tobacco heating devices

The U.K. manufacturer and supplier of advanced materials coordinated all aspects, from initial concept to final solution, including a fully optimized production process.

Read MoreLaboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites

Four-year, 12-million-euro LaiLa project with Helmut Schmidt University combines R&D with industry collaboration to solve real production pain points, validate solutions in digital lab/model factory at CTC and transfer knowledge to supply chain including customized training.

Read More

.jpg;maxWidth=300;quality=90)