Materials

Ilium Composites chopped strand mat demonstrates compatibility, sustainability and durability

Chopped strand mat (CSM) under the ULTImat range of reinforcements protects against osmosis and chemical erosion for maritime and relevant constructions while delivering smooth surface finishes.

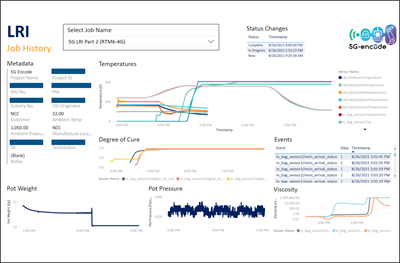

Read MoreNCC and Synthesites work toward intelligent manufacturing for resin infused composites

The National Composites Centre (NCC) and Synthesites develop an advanced closed loop control system for resin infusion with non-invasive sensors, real-time resin flow monitoring and accurate, in-situ estimation of online viscosity and glass transition temperature.

Read MoreCompoTech, Bilsing carbon fiber gondola beam development key for simplifying tooling management

Stiffer EOAT design for automotive tandem press line tooling increases load capacity and productivity, overcomes strokes per minute limitation and improves factory interchangeability.

Read MoreAthletic shoe developed with repurposed thermoplastic waste

Manufactured via a single-step molding process, Decathlon’s Traxium Compressor soccer cleats propel the sporting goods market toward more recyclable solutions.

WatchPRF Composite Materials launches Q.tool prepreg tooling system

Newly developed Q.tool combines RP800 epoxy with 1,020 g/m2 bulk plies for increased layup speed, reduced number of debulks and better surface finish.

Read MoreSaertex enters into sustainable partnership with Terre de Lin for flax fibers

The Normandy-based supplier will enhance Saertex’s textile composite capabilities in markets such as marine and sports and leisure.

Read MoreMitsubishi Chemical Advanced Materials, AMAC cooperate on thermoplastics business in Europe

Partnership to strengthen and develop sustainable composite business activity internationally, includes opening of KyronTEX textile production line in Germany.

Read MoreNotox surfboards combine upcycled carbon fiber from Airbus with Sicomin bio-resin

One-hundred percent upcycled fabrics declared unusable for aerospace applications go through a wet lamination process with vacuum bag consolidation to produce the sustainable Notox R-Carbon products.

Read MoreArkema introduces Clearstrength XT 151 toughener powder for epoxy formulations

The toughener is tailored to boost the durability and performance of thermosetting resins without compromising processability.

Read MoreArcher Aviation plans to work with Hexcel to advance eVTOL production capabilities

Under the proposed relationship, Hexcel will supply its high-performance carbon fiber prepreg material for the production aircraft.

Read More