Materials

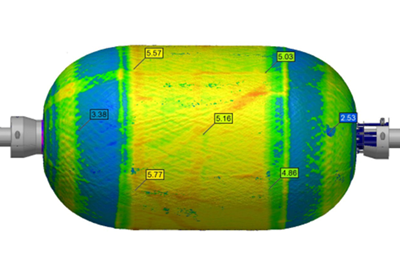

NCC’s all-composite Type V tank demonstrates future composite space tank technology

SpaceTank project delivers a 96-liter carbon fiber composite tank with 4.0-5.50-millimeter nominal wall thickness for 30% weight savings in launch vehicle and satellite propellant tank applications.

Read MoreHexcel prepregs power cleaner ocean transport with Chantiers de l’Atlantique Silenseas project

HexPly supplied M9.6 carbon fiber prepregs for a 34-meter-high cruise ship mast. Silenseas production scale-up objectives for future vessels intend for the development of three 66-meter-high carbon fiber masts.

Read MoreVestas looks to scale up blade recycling partnership solution offering to U.S. and other regions

Vestas seeks areas where local recycling infrastructure is robust, and customer demand can be established. Recycling methods can include cement co-processing, gasification, development of new composite materials and reclamation.

Read MoreIllini Solar Car team composite vehicle paves way for success in American Solar Challenge

AERO Sustainable Material Technology sponsorship sustainably safeguards the carbon fiber body of the car from degradation, further contributes to team placement.

Read MoreMETEOR project studies optimization of thermoplastic prepreg production

Completed project aimed at optimizing and reducing the cost and energy involved in CFRTP prepreg manufacture, with the end goal of industrialization.

Read MoreCarbon fiber in automotive: At a dead end?

For decades, carbon fiber has failed to break through into mainstream automotive applications as the composites industry has hoped it would. Alternative composite applications suggest future opportunities still remain bright.

Read MoreRML Short Wheelbase vehicle nears completion

While it has an unusual name, this limited-edition British sports car is fast, stylish and composites-intensive.

Read MoreAutonomous, electric shuttle retrofitted with CRP Technology Windform materials

Advanced 3D printing production process and Windform composite materials used to manufacture the required motor cover and washer reservoir flap valve components, account for Olli 2.0’s pod-like shape.

Read MoreTeijin to carry out life cycle assessment of carbon fiber

Life cycle assessment (LCA) will aid in calculating carbon emissions for all of its carbon fiber filament applications.

Read MoreUniversity of Limerick seeks to improve composites recycling solutions

VIBES project focuses on recycling technology maturation to develop bio-based, intrinsically recyclable materials for waste elimination, circular economy.

Read More