Materials

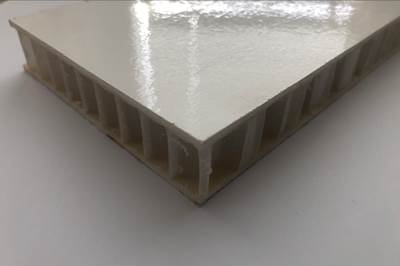

EconCore, Renolit honeycomb sandwich panel developments explore diverse applications

EconCore lightweight honeycomb enables Renolit Gorcell product line to overcome technical challenges and push the application spectrum for automotive and other markets like furniture and garden.

Read MoreNASA Ingenuity helicopter succeeds in historic first flight on Mars

Ingenuity’s two 4-foot-wide carbon fiber and foam core rotor blades successfully interacted with Mars’ gravity and atmosphere, logging a total of 39.1 seconds of flight.

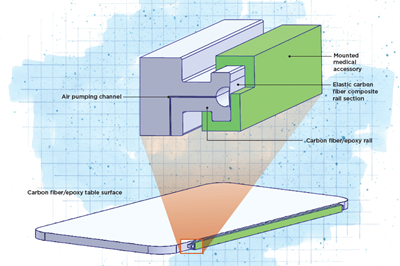

Read MoreDesign innovations improve efficiency of composite medical table

WIT-Composites' efforts to design a more effective all-composite surgical table led to development of complex components and an elastic carbon fiber material.

Read MoreTRB Lightweight Structures manufactures prepreg material in-house to streamline part production

Company reaches 25,000-part milestone via rapid-cure prepreg technology.

Read MoreCato Composites expands thermoplastic composites production capacity

Larger facility and expanded development team to increase market position and fulfill new orders in safety and sporting goods.

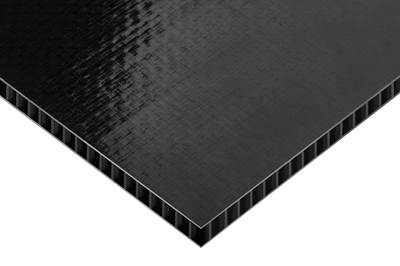

Read MoreThermHex, Brixtone complete honeycomb core panel production for 400 commercial vans

Cargopan wall panels incorporate ThermHex polypropylene honeycomb core for increased robustness damage resistance, waterproofing and a tripled lifespan.

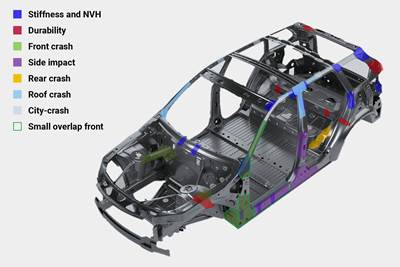

Read MoreComposites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

Read MorePurdue University to establish Thermwood LSAM research laboratory

Industry-funded research to pursue large-scale composite thermoplastic additive manufacturing, with the goal of providing services to enhance, encourage and expand the adoption of large-scale AM for diverse industrial applications.

Read MoreGerman composite specialist INVENT collaborates in SUSTAINair for increased aircraft circularity

Three-and-a-half-year, 11-partner EU project will include metals and composites spanning design, manufacturing, maintenance, repair, assembly and recycling.

Read MoreWing of Tomorrow ribs: One-shot, thermoplastic, OOA consolidation

GKN Aerospace’s carbon fiber thermoplastic aircraft rib design accomplishes 45-minute cycle times, reduced weight and competitive costs via a customized press system.

Read More