Materials

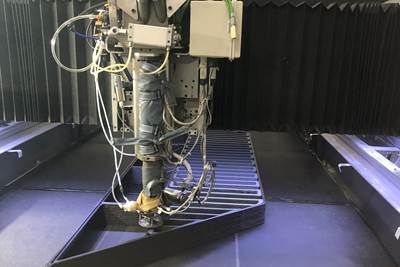

Cincinnati Inc. BAAM printer demonstrates 3D printing with recycled composites

Dual-material thermoplastic extrusion system produces monolithic composites tool exceeding 10 feet in length, without manual intervention.

Read MoreTeledyne CML Composites invests in thermoplastic processing capability

In conjunction with the NCC, the automated processing cell supports high-performance thermoplastic and compression-molded thermoset parts production for the commercial aerospace and defense markets.

Read MoreWH Lipex introduces single fiber applicator for glass fiber sizing implementation

Coating module individually displays glass fibers for complete fiber wetout and improved bonding capabilities.

Read MoreContinuous Composites, Siemens Energy apply high-performance materials for power generators

Continuous Fiber 3D Printing (CF3D) enables new designs for AM with thermoset GFRP composite and exceeds material requirements for generator components.

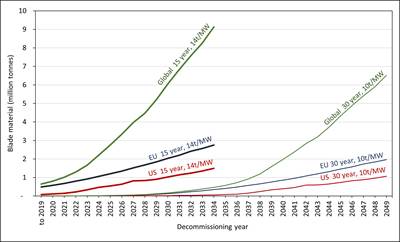

Read MoreDefining the landscape for wind blades at the end of service life

There is a generation of wind turbine blades at or near the end of their useful life. Disposing of them, recycling them or reusing them requires a better understanding of the blade end-of-life landscape.

Read MoreMagma Global delivers high-pressure composite riser pipe to HWCG consortium

Carbon fiber-reinforced thermoplastic m-pipe designed for flexible and more rapid deepwater oil and gas emergency responses for the U.S. Gulf of Mexico.

Read MoreHeatcon to distribute Hexcel prepregs for UAV/AAM market

The partnership includes North American distribution of Hexcel carbon fiber prepreg tapes and fabrics to support urban air mobility manufacturing and repair.

Read MorePartnership promotes Hypetex colored carbon fiber materials to North American market

Massachusetts-based CompositesTech will perform sales and marketing for the Hypetex fiber reinforcement portfolio and introduce it to new customers and markets.

Read MoreMAMBO tests the waters for 3D printing large marine structures

With its MAMBO boat, Moi Composites demonstrates use of its continuous fiber 3D printing technology for customized, automated production for the boating industry.

Read MoreWest System provides materials for Atlantic-crossing rowing boat

The crew plans to be the first to sail its carbon fiber/fiberglass composite, pure class rowing boat non-stop 3,800 miles from Europe to South America.

Read More