Out of Autoclave

Highlights: JEC Europe 2014

Composites enable high performance and lower weight in washtubs, wheelchairs and engine exhaust cones. Plus new, ultralight materials.

Read MoreComposites Industry Outlook: Positive

An exhibition like CAMX 2014, which draws together all aspects of the composites manufacturing industry, demands a comprehensive and thorough review of the health of the industry and where it’s headed.

Read MoreDow epoxy joins the fast-cure race

Dow Automotive made waves at JEC Europe with the debut of VORAFORCE 5300, a low-viscosity, <90-second cure epoxy for automotive composites molding applications.

Watch3-D preformed composites: The leap into LEAP

The LEAP jet engine is the next generation of the successful CFM56 engine for narrow-body aircraft which powers more than half of the commercial aircraft ordered in the past decade.

Read MoreAlbany Engineered Composites: Weaving the Future in 3-D

This 3-D weaver turned composite component supplier pursues a future in 3-D structures through continuous technology development.

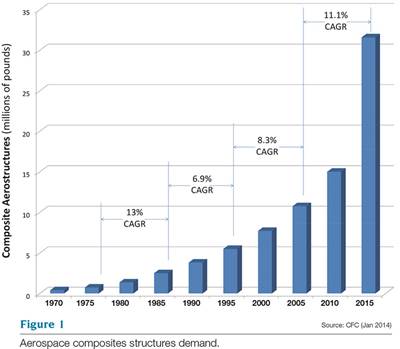

Read MoreThe market for OOA aerocomposites, 2013-2022

In the coming decade, out-of-autoclave technologies will increase composites penetration into primary flight structures.

Read MoreAFP/ATL evolution

A view of the trends in automated fiber placement and automated tape laying from inside the supply chain.

Read MoreIt's time for the U.S. to invest in advanced composites manufacturing

Consultant and president of Quickstep Composites (Dayton, Ohio) Dale Brosius suggests that it’s time for an Institute for Manufacturing Innovation (IMI), created under the proposed U.S. National Network for Manufacturing Innovation (NNMI).

Read MoreOne for the history books?

HPC editor-in-chief Jeff Sloan wonders if a current and radical proposal for change in the way aerospace materials and processes are certified — namely, certification of design/simulation software — will find the brave advocates it will need to become a watershed in aerocomposite history.

Read MoreNo-oven, No-autoclave (NONA)

Room-temperature cure epoxy composites with a 400°F Tg, comparable properties vs. commercial systems without external heat or post-cure, and offering reduced cost and cycle time. Really?

Watch