Out of Autoclave

RVB Infusion = Light RTM?

There is some difference of opinion as to whether parts infused under reusable vacuum bags (RVBs) are the equivalent of those produced by Light resin transfer molding (RTM). See why.

Read MoreRVB insider insights

Experts in reusable vacuum bag technology share insights into bags adapted for autoclave use.

Read MoreReusable vacuum membranes: Coming of age?

Durable custom elastomeric bags cut consumables cost and boost rate production.

Read MoreRecycling carbon fiber back into the automobile

There is some hope on the near horizon for reclaiming carbon fibers from the estimated 40 to 60 percent scrap volume that results from the manufacture of automotive CFRP.

Read MoreSPE ACCE 2013 Review

The SPE’s annual Automotive Composites Conference & Exhibition gets a bigger venue, an expanded program and its best attendance ever.

Read MoreAutomotive CFRP: The shape of things to come

CAFE and CO2 emission standards will drive auto OEMs to fully examine the physics of fuel economy, but will that, at last, steer them toward extensive use of carbon fiber composites?

Read MoreIBEX 2013 Show Review

Evidence of a marine industry rebound and a trend toward supplier M&A as the world’s largest boatbuilding trade show looks ahead to smoother sailing … and Tampa.

Read MoreAutomotive, going forward?

CT editor-in-chief Jeff Sloan asks when, if and how composites professionals will be ready to meet the challenges of significant use of carbon fiber composites in automobiles.

Read MoreBombardier sheds light on Learjet 85 composites manufacturing

Bombardier composites expert Pierre Harter talked in detail at SAMPE Tech about where and how composites were used on the forthcoming Learjet 85.

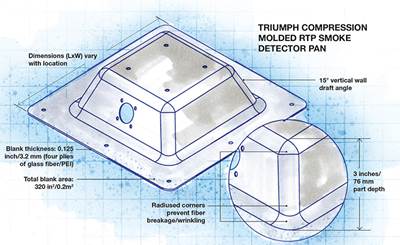

Read MoreCompression molding mass out of aircraft interiors

Continuous carbon fiber-reinforced thermoplastic lightweights smoke detector pan and slashes production cycle time.

Read More