Out of Autoclave

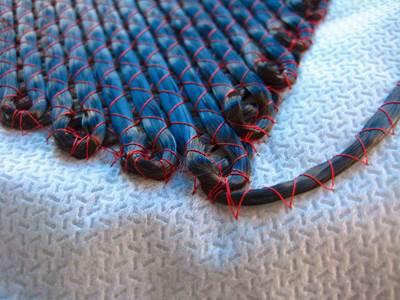

Tailored Fiber Placement: Besting metal in volume production

Affordable automated production of highly optimized preforms and parts.

Read MoreParis Air Show 2013: A century of aircraft progress

Torrential rains couldn’t dampen the spirit of innovation or stop the flood of business aerospace announcements.

Read MoreTooling up for larger launch vehicles

NASA and Janicki Industries demonstrate composites’ cost advantage in tooling for fabrication of 10m/33 ft diameter payload fairing for next-generation launch vehicle.

Read MoreWanted: Big thinkers and risk takers

Quickstep Composites (Dayton, Ohio) president and independent consultant Dale Brosius challenges the auto industry to think big and take risks in composites R&D.

Read MoreIBEX 2013 preview

Louisville gets the nod for the fourth year in 2013, but in 2014 IBEX returns to Florida by popular demand.

Read MoreAdditives and modifiers: Matrix optimization

New and reengineered modifiers for thermosets and thermoplastics target previously elusive goals in composites processing and performance.

Read MoreModular design eases big wind blade build

First segmented composite blade increases power generation, eases installation and keeps weight and costs in check.

Read MoreBig blades, big innovations

In the process of designing its G128 wind turbine blade and the INNOBLADE segmented blade technology that simplifies its transport (see “Modular design eases big wind blade build,” under “Editor’s Picks,” at top right), Gamesa (Vizcaya, Spain) has introduced several innovative auxiliary technologies that reduce cost and simplify processing, particularly in the context of blade delivery and installation.

Read MoreIf not automotive then ... what?

CT columnist and president of Dayton, Ohio-based Quickstep Composites Dale Brosius says it’s not too early for composites industry operatives who are pursuing the automotive holy grail to begin exploration and market development elsewhere.

Read More